|

10/05/23 Fast forward three years and a bit more. I think I mentioned perseverance in an ancient post :) Well, the D7 project is alive and has been moving forward. The major gating factor is the batteries. I have been busy - 20+ patent applications filed, six issued so far. Two companies started - ModBatt and metaLINXX. Got investors, hired people, and so on. None of this is easy. On the plus side, technology moves forward and Cascadia now has very nice integrated motor/inverter units, the IM-375, which did not exist three years ago. More power, less space/weight, and a lot less cost.

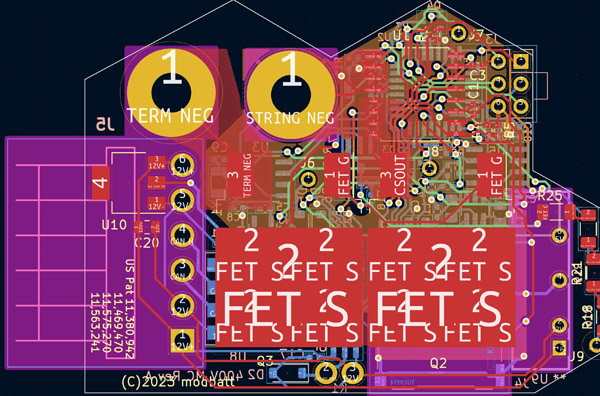

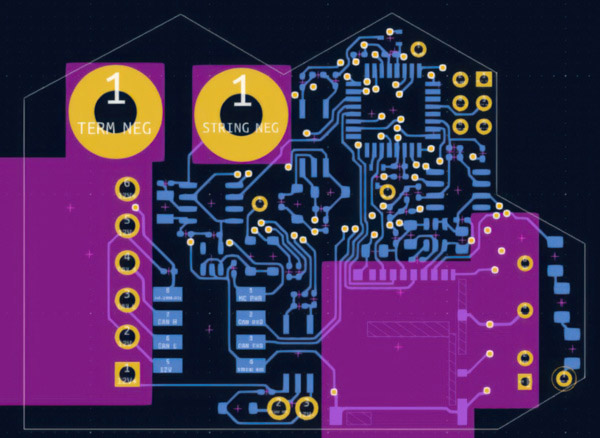

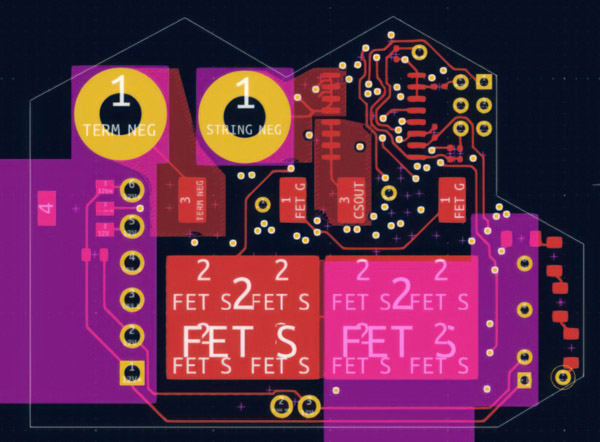

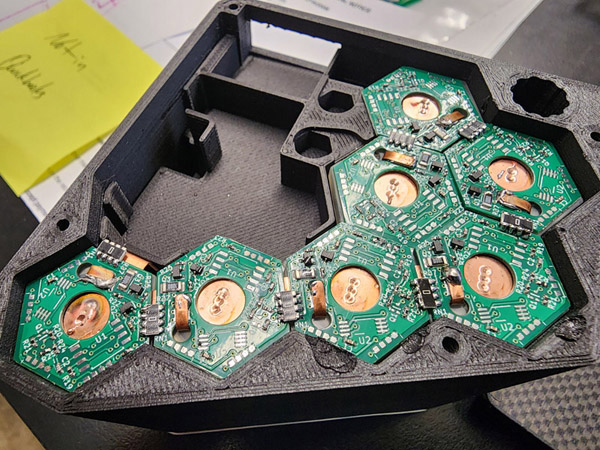

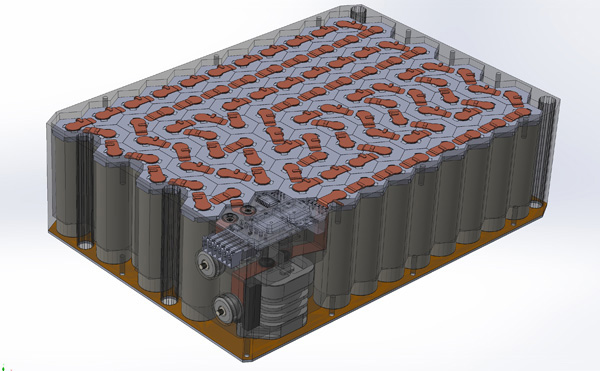

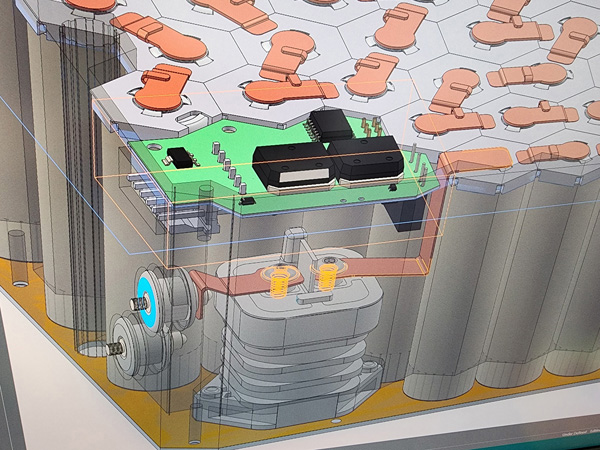

And now we have a D7 lead customer. It is a very high profile individual with visionary ideas - I can't disclose who it is, nor what the finished car will look like. But I can provide some entineering-level updates. First, the batteries. I've pursued the IP-first strategy, writing patents (because I can do that myself) to build a foundation. In the process, I have figured out a lot of things - which leads to more patents. The tech overview linked on ModBatt site has a list for anyone geeky enough to dig. The site also has a whitepaper and links to some articles. the metaLINXX site has info on the LCTs that will control, well, everything really. Now we're building the batteries. 400V modules first, for a major OEM, then 800V ones for D7/D8 and next gen D47. I won't go into technical details here, the above links have the info for those interested. It is very different from what's been done before, and solves all the problems. Really. It's been forever since I've done circuit design and board layout, but after trying to get several people interested I ended up just doing it myself. I'm better at it than most, anyway :) There are two separate circuits (tried doing at as one but not practical as it turns out).

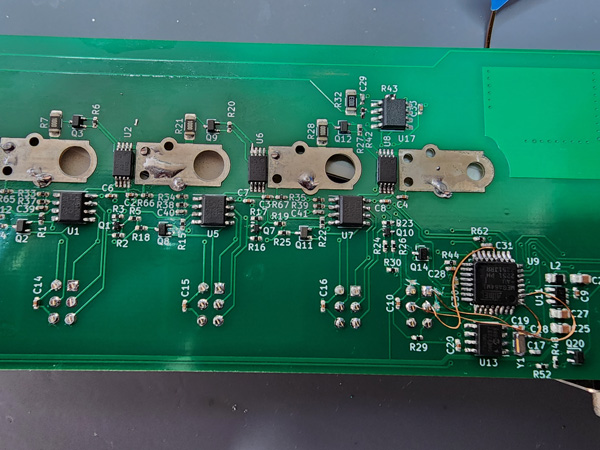

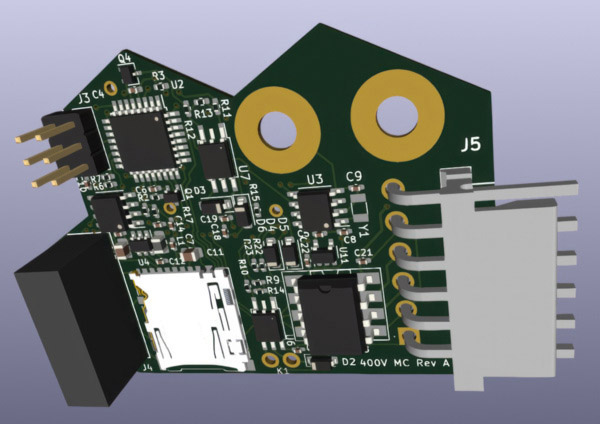

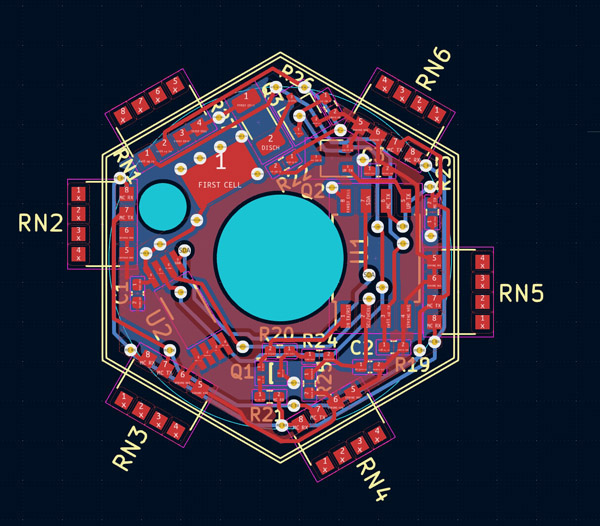

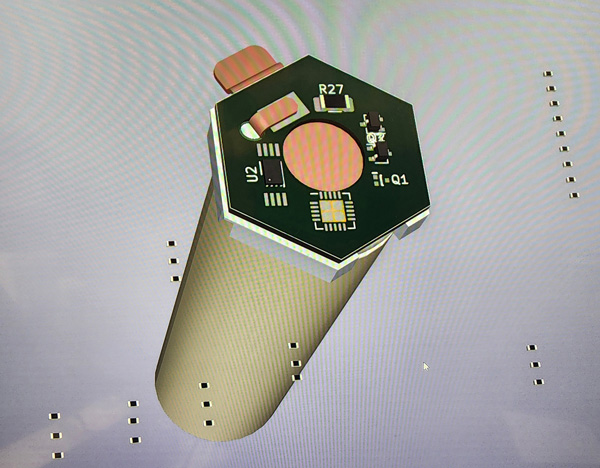

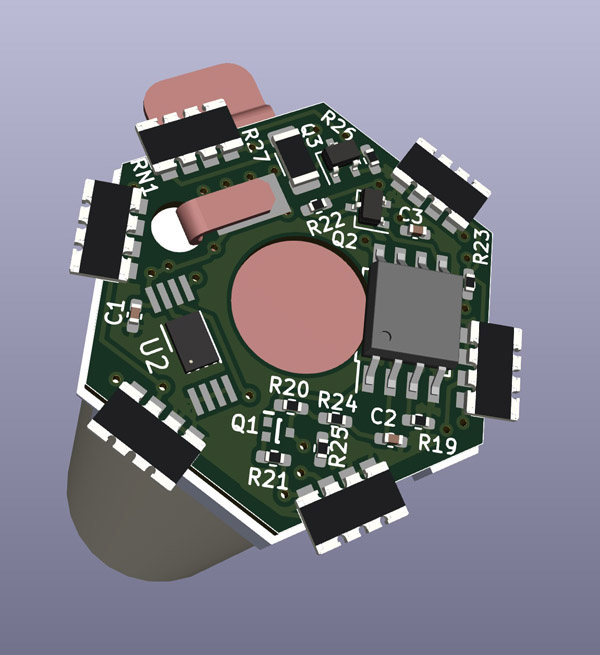

The module controller, and the cell monitoring circuits, one per cell. Both are very challenging. The module controller has a combo of digital/analog, numerous power supplies, some isolated, 400V separation, and 50A current. With very specific packaging/mechanical limitations.

I got it done, staying up all night before a zero-notice trip to Florence (see experience section). We wanted to work with US based vendors and requested quotes from several. Also from China. We had fully built boards in hand from China, for 1/10th the price, before we even got a quote locally. There is a reason all manufacturing is there - they are just better at it. Sad but true, really wish it wasn't the case but can't ignore reality. The cell circuits are another challenge. Had to solve numerous electrical and mechanical problems. Still working out the process but it's moving forward.

Before tackling the 400V modules that can deliver 20KW of power if accicentally shorted, we're starting with a 28V prototype.

Since Sam has to be able to assemble the modules in high voltage protective gear, we're practicing that from the start. It's doable.

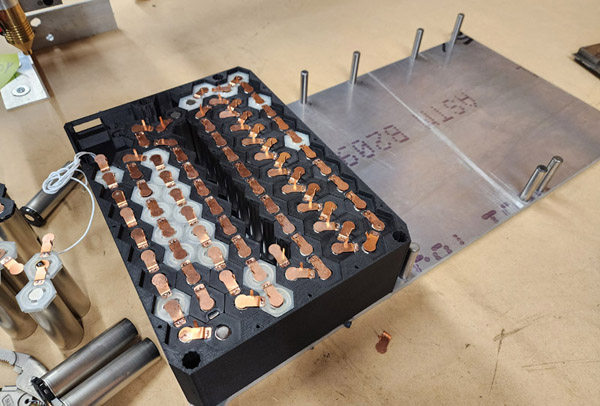

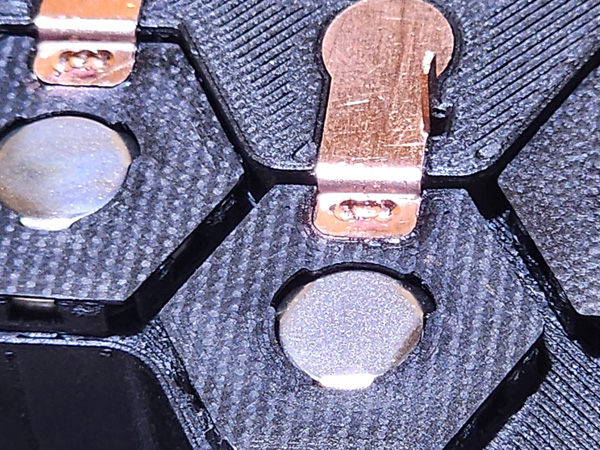

The actual modules required a number of unique solutions but we're sorting it out. We even tried laser welding the copper interconnect to cells. Didn't work :)

Ended up making injection-molded cell 'tops' and stamped copper connectors.

Below is an early concept test for comparison. It takes many steps.

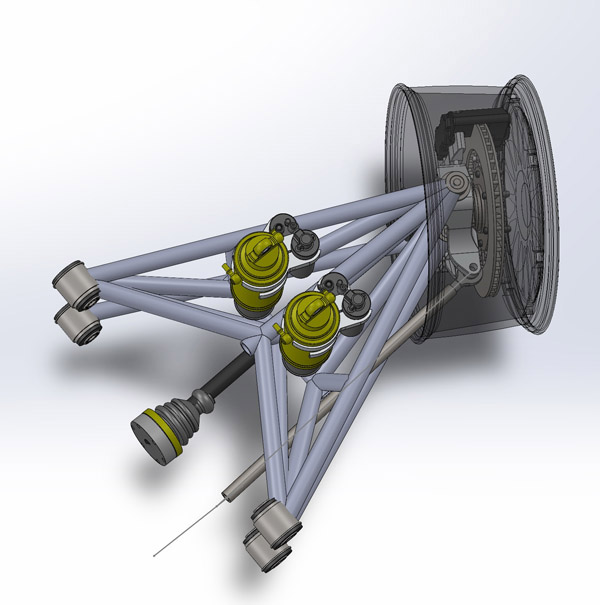

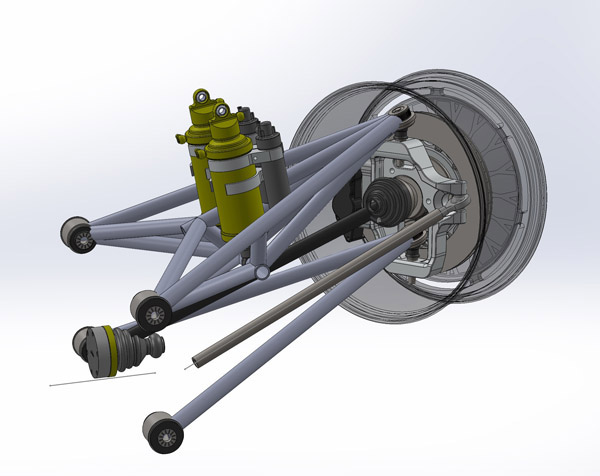

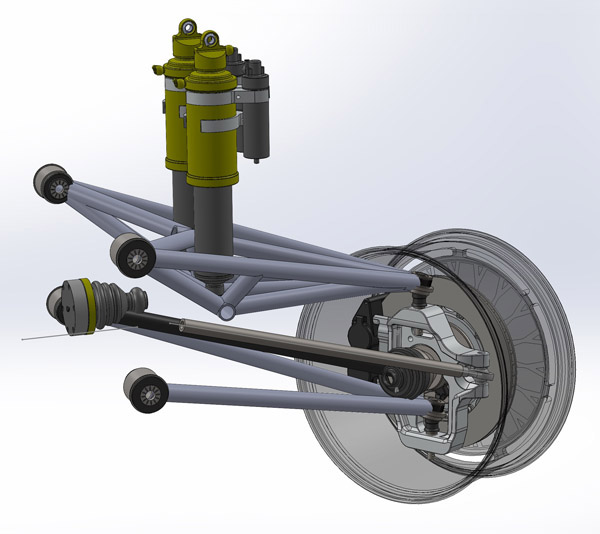

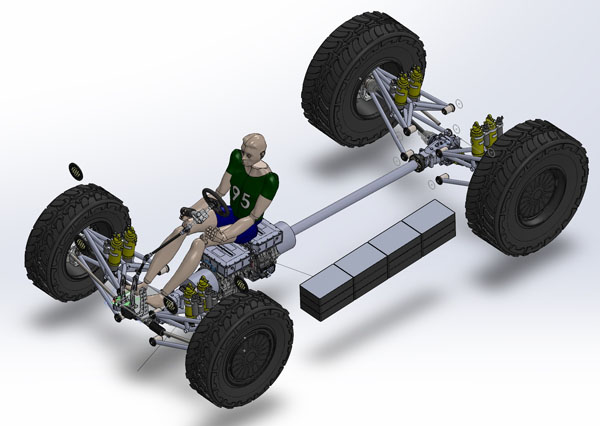

Many months of development, trial and error there. But it's coming together. And now that the batteries are materializing, we can do some mechanical stuff. The suspension will have 18" of travel and 40 degree steering angle, which presents a number of challenges. Solvable. The suspension uses Penske air springs and shocks. The reason for double units is that the travel dictates motion ratio, motion ratio dictates force, and it just takes two to handle the numbers. Yes $20K in shocks/springs alone.

Per customer requirement, the wheels and tires are not small - 35" front, 42" rear.

Another challenge is logistics - some parts were ordered a year ago and are only now starting to trickle in. Halfshafts and differentials from SADEV received today.

Hopefully will be less than three years before the next update :) There is also progress on D47. D8 and D9 will move ahead before long as well because they all have been waiting for the same parts.

|