|

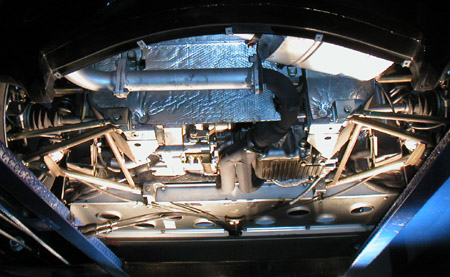

01/02/03 In the hopes of furthering the progress, I decided to make a list of everything that needs to be done to the Elise. Here it is: - Replace gearbox with closer-ratio one - Replace cluch and throwout bearing - Install the engine brace kit - Install the shifter bushing upgrade kit - Fix or replace throttle cable which was misbehaving and sticking on some occasions - Bleed the brakes - Fix the fuel spillage problem I will probably rent a storage space, put the Westie and the kart there for the moment so I have room to work on the Elise, get the Elise back up and running, then swap it with the Westie and take care of that. Or should I finish the Westie first? Decisions, decisions. I could of course keep putting it off but the new track day season is closer than I like to admit.... 01/25/03 Finally rented the storage space, moved the Westie, the kart and a bunch of other stuff out of the garage, and started on the Elise. With undertray and diffuser removed it's easy to see how difficult the task is going to be. It will involve removing the left lower wishbone, unhooking the right upright and undoing a lot of impossible to get to bolts just to get to the gearbox. This is why I've put off installing the new one for over a year....

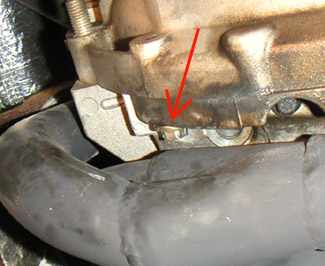

But of course there's more to it. A while ago I had installed Lotus aftermarket header, with great difficulty (see page 2). Well, it so happens that the new header greatly limits access to one of the gearbox bolts.

There is no room to even put a box-end wrench on it. So I tried loosening it with an open-ended wrench, promptly rounding the head. It of course has to be the tightest bolt in there. So now whatever I do about the bolt, the header has to come out to do it. Which means pulling out all the heatshields and getting to a couple bolts that are virtually inaccessible.

But again there is really no choice. On the plus side, since the super-duper coating on the header has been flaking off, I can take it back to the place that did it and have them recoat it.

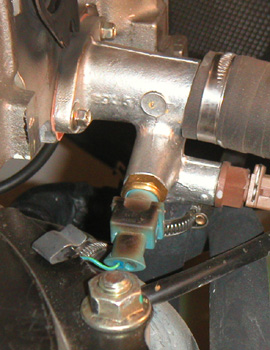

That's whenever I finally work up the energy to tackle the task, which won't be today. And this was the reason for clearing other stuff out of the garage. I kinda suspected the Elise will take a while to take care of, and this gives me the luxury to do it at my own pace without moving things around or leaving the mcoupe outside. The whole experience is of course a much needed lesson in designing for serviceability - lest I be tempted to do something too clever in the dp1 and regret it forever after. Well, hey, I seriously need a silver lining in this particular cloud :) 01/26/03 Figured today is as good a day as any and pulled out the exhaust. It only took 3 hours (this of course considering that the car was already on the lift with the undertray and diffuser removed). The procedure involved removing several heat shields and their brackets. The oil filter also had to come out - ah well, the car needed an oil change anyway. The header coating is not in too great a shape.

It also didn't work that great as a thermal barrier, as evidenced by a connector located a full 4 inches from the nearest pipe.

I have seen the headers glow at idle. So I guess when I suspected that black wasn't the best color choice for the coating, I may have been right afterall. I now have to get the header re-coated and am debating whether to take it back to the place that did it originally and try to have them redo the work free of charge, or just take it somewhere else. I also need to come up with some shielding for the connector! Another thing I realized is that one of the exhaust studs was missing. So now I have to procure one and a corresponding nut. Might as well get new gaskets too... Again, on the plus side, this needed taking care of anyway. And the gearbox will be a lot easier to access without the header in the way. A blessing in clever disguise? I choose to see it this way :) 02/02/03 Finally worked up the energy to do more work on the Elise. Did a lot of disassembly, after figuring out how to support the car on the lift with wheels off. Some bolts are very difficult to get to. This car was definitely not designed for ease of maintenance! I remember changing the engine and clutch a couple of times in my old Fiesta - a task that was easily accomplished in 3 or 4 hours, without a lift. In contrast the Elise project is turning into a multi-day affair, despite having much better equipment and facilities.

The halfshafts are now disengaged from the gearbox, the right upright is partially disassembled, the left lower wishbone is disconnected, air intake removed, left arch liner removed... Now I need to unbolt the starter (easier said than done), support the engine, figure out how to get to the mounting bolts for the gearbox, then maneuver the thing out. I somewhat dread to see what the clutch looks like - it did not sound good at all. And from what I've learned from a newsgroup online, the installation is going to be more difficult than removal. Joy. Also discovered that one of the rear toe link bolts was loose. I'm sure that didn't have any positive effect on handling! But at least I caught it before it got much worse. 02/04/03 Had to ask online for tips on removing some bolts. No revelations but I did get some confirmation that it IS as difficult as it looks and I also got some encouragement. Internet is indeed a wonderful medium :) Armed with that I did in fact remove all the pesky bolts. Took a few hours. What didn't help is the fact that the breaking torque on most of the bolts was in excess of 150 lb-ft. Don't know if this is due to some procedure Lotus uses or just the fact that my car is over 3 years old now. Sure adds another level of challenge to it. Six-point sockets help, but only just.

The good part is that now the box is ready to come out. Which I decided to leave for tomorrow. In removing the dust shields I saw a lot of metal flakes. Which makes me suspect the the insides of the bellhousing look as bad as they sounded. We'll see. In the meantime picked up the recoated headers. Will be interesting to to see how this version holds up. Right now it's a little hard to picture the whole thing back together.

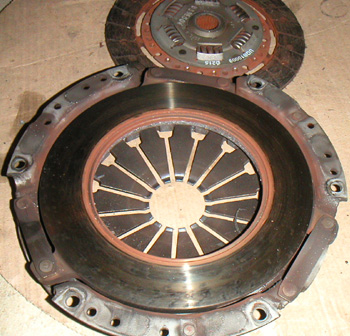

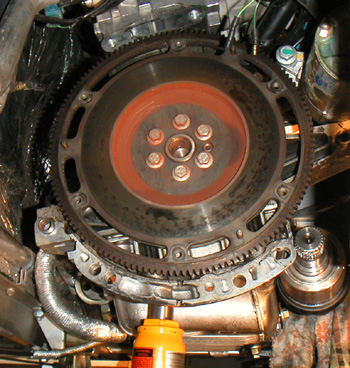

02/05/03 Ok, the gearbox is out and it's not pretty. The thrust bearing had seized up and was completely destroyed, chewing up the gearbox case and spreading debris all over the insides of the bellhousing and into the clutch.

The gearbox case got torn up pretty bad, and if I didn't have a replacement box ready to go I'd be buying one right now! The clutch itself actually wasn't damaged too badly, but I'm replacing it with an upgraded one anyway so it doesn't matter. The nice lightweight steel flywheel seems to also have escaped unscathed, save for some surface glazing that I'm sure can be easily cleaned up. There are no scratches on it.

So now I need to figure out a complete list of everything I should do while the car is apart, and do it. May need to order some parts. Also contemplating whether to get flywheel and clutch balanced.

The lift is certainly nice but it is not without its hazards, as I had forgotten that the car is jacked up from normal position and ran it up into one of the overhead fluorescent lights. When all was cleaned up only two tiny dings on the car (the size of rock chips) but at the time it sounded like the end of the world in a shower of glass. I feel really stupid, but nothing to do now except move on and hope the lesson is learned. 02/15/03 Finally got the car mostly reassembled (enough to where it's driveable) and took it out for a quick run. The new box has straight-cut gears and is quite loud! Sounds quite cool, actually, though I wouldn't want to put up with it on any kind of long drives. For a track car it's perfect. The new ratios are great - can't wait to get it out on the track. Quite a bit of tinkering remains but the toughest part is (knock on wood) behind me. Took roughly 35-40 hours to get this far. Whew. |