|

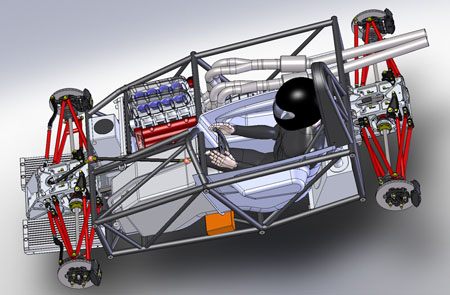

04/02/11 Busy day yesterday! Much progress, this is the fun part where a lot of very visible things happen. After this is fitting things like wiring and plumbing which is far less exciting... Started with tacking the rollbar 'cover' in place. It does serve a structural purpose (after it's fully welded) but also makes it cleaner both visually and aerodynamically.

Next was the assembly of the center drive unit. As previously mentioned, this version drives the fronts via a sprag clutch while the rear drive is permanent. Based on how the testing goes we might build a 35/65 split planetary unit that I already have designed.

And finally, the engine is positioned and the mounts are tacked in.

The drive flange in the picture above is just used for alignment. In use there will be a large 'guibo' elastic coupler between the gearbox and the center drive unit, both to reduce shock loads and to allow for any slight misalignment due to various forces. A very long list of tasks remains before the car is drivable but this feels like real progress. The design has certainly come a long way from the initial sketches, nearly nine years ago!

06/30/11 Sometimes things go slower than I'd like and this project has had some setbacks. The molds for the bodywork are still not done, the floor plug needs finishing, a lot of other things have to get accomplished. Soon. We are a small team trying to create four completely different cars from scratch simultaneously (plus other projects) so it's not entirely unexpected but can be frustrating nevertheless. So as an additional motivation I did some renderings of the car, to remind myself of the target :) Click on each for larger version. Several items on the list are currently being worked on so expect updates shortly. 07/06/11 Pete has been a great help around the shop - wish he could stay around longer than a month! His newest project is prepping the plug for the floor molds.

The design is an evolution based on everything we've learned from original prototype and the dp4. On the side you can see the profile - the entire car is an inverted wing which has a lot of advantages over more traditional approaches. The two main reasons it's not normally done are packaging constraints, especially at the back, and racing rules. Neither is a problem in the case of dp1 or dp4 (the latter still complies with DSR regs which are fairly permissive as far as racing rules go). Still, the devil is in the details so some tweaking is likely as we go forward. Should be fun. And no, I'm not going to explain it any more than this :) 07/13/11 If it seems there hasn't been much activity on the dp1 front lately, well it's true. Running a business is a constant juggling act of deadlines, priorities, resources, emergencies and so on. For a while we weren't really in a position to make much dp1 progress (but other things got done). Now you're going to see a lot of action here. The bodywork molds are progressing...

The floor plug is coming along, to be followed by molds and then actual parts...

The left fuel cell is now mounted, the right one has been ordered...

A whole lot of other pieces to the puzzle are in the air and about to land in their designated spot. Pilot pod, bodywork, floor, wing, tires, plumbing, electrical, paddle shifter, and a number of other items. Much more to come :) 07/15/11 There is a bunch of progress in the real world (on this car, as well as the others - new cush drive installed on the proto, motor is back in and running in the yellow car, and so on). In the meantime I've finished the dp1-specific Pilot Pod design. The forward section is shared with the dp4 but the main cockpit is different due to a more laid-down driving position and other packaging differences.

The files have already been sent off for machining, hopefully this one will go quickly with everything we've learned. Floor plug is nearing completion as well while the bodywork molds are being worked on at Stohr. This is fun :) 07/26/11 The bodywork mold is nearly done...

First body is expected in less than two weeks. Getting pretty excited to see it in the flesh. Floor plug is nearly done and mold construction will start next week. This car is now the main focus so there will be lots of rapid progress. Just designed floating rotor hats for the brakes and they're being made. Pilot pod and other parts are in the works as well. We're going to upgrade the oil pump on the V8 to a newer design so hopefully those parts will be here in two weeks or less. Working on fittings, brackets, plumbing and similar bits right now. Mid-August is the target first start. We shall see...

07/28/11 More progress - the steering is in. This car gets the Geartronics paddle shifter. A really neat system that I'm looking forward to experiencing first-hand.

The bolts on the steering wheel are temporary - the actual items will be much more appropriate looking :) The pedals are mounted as well. We are awaiting the completion of the Pilot Pod before all the controls are finalized. 08/04/11 A few updates. The bodywork mold is now done and the first part is due in less than a week. Stohr only has an 8'x8'x8' oven and the mold fits in with literally 2" to spare, when sitting diagonal. Yes I did check this in CAD before we started.

The floor plug is now complete and has been dropped off to get the mold made. The forward portion of the Pilot Pod is done. The plugs for the main portion are being machined.

Lots of progress on the mechanical side, too. We're pushing hard to have the car ready to run by the 15th but it's a tall order. Lots of wiring and plumbing has to happen by then and there are still many parts to be fabricated (and some still need to be designed). We'll see how it goes. 08/10/11 A few more bits of progress. While Tristan is welding miscellanous brackets and assembling bits, I've finished the updated design of chain management system and it's now being made.

The Pilot Pod side plugs are here and I've started on their prep.

For this car I've decided to try floating rotor brake setup, so I designed the hats and they're now on the car. We'll see how that works. If the scalloped rotor proves inadequate we can switch to a regular one later. Lots of testing ahead!

08/24/11 Things are progressing. The engine is now back together with the new pump and installed in the chassis.

The right side fuel cell has arrived from FuelSafe and is now installed, bringing total fuel capacity to 10 gallons. Should be good for 2 track sessions at a time (about 40 minutes).

The Pilot Pod plugs are now glassed, primered, sanded, primered and sanded again.

Ready for final coat of primer, then more sanding, polishing, waxing and finally parts. Composites are a LOT of work even when the base shape is CNC'd. Since Tristan has been busy with the mechanical bits and we don't currently have an intern the sanding has been up to me. With the heat and humidity lately I've dubbed the composites room 'the sweat lodge'. All part of what it takes. A final bit, not directly D1 but I'm too tired to make a separate D4 update... The Pearl has seen much tracktime and we cover the nose with tape to limit the damage from debris. This is what it looks like after 2 trackdays:

Having learned from the splatter and rock chip patterns we've determined that paint protection film is a necessity. I've done my own installs on some previous cars I've had, most notably the first Elise and the two MCoupes, and I know how much work it is. So this time we've deferred to the pros at OneSource to do the install and develop a kit we'll be selling as a (strongly recommended) option. They came out and did the yellow car which is in for some upgrades - a great job, especially given all the curves and complex shapes. The film goes up to the louvers on the fenders and you have to really look close to see it - even on the actual car. In pictures it's completely invisible.

The D1 will have paint protection installed as standard, of course.

|