|

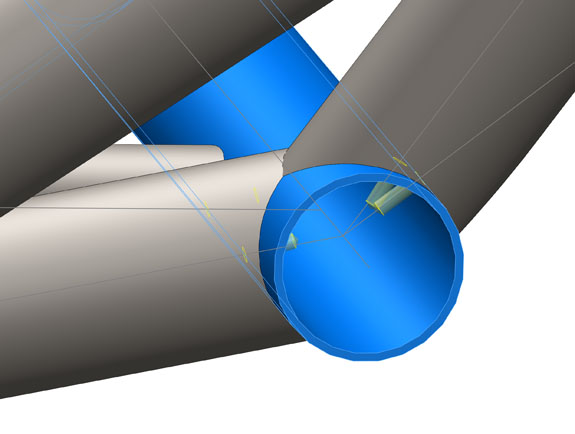

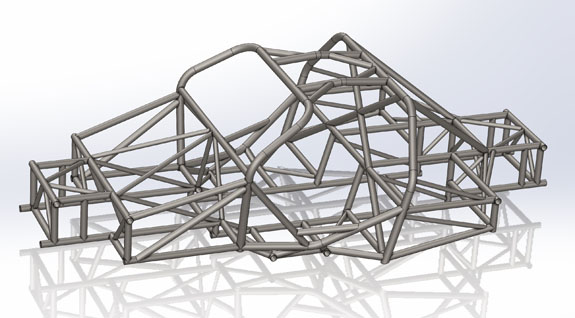

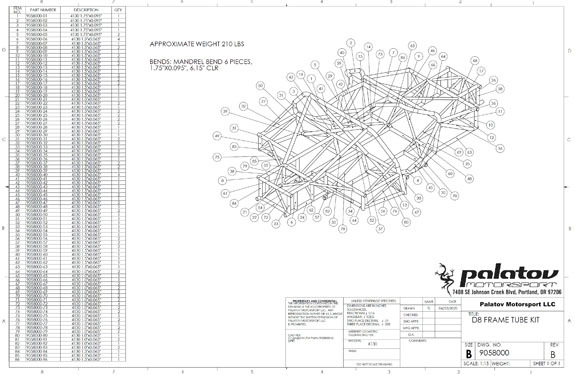

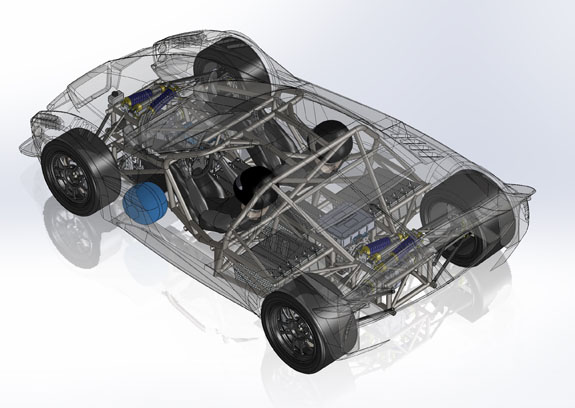

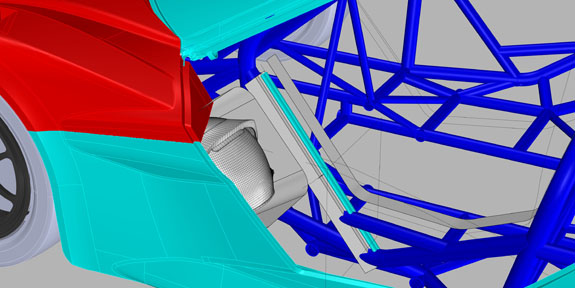

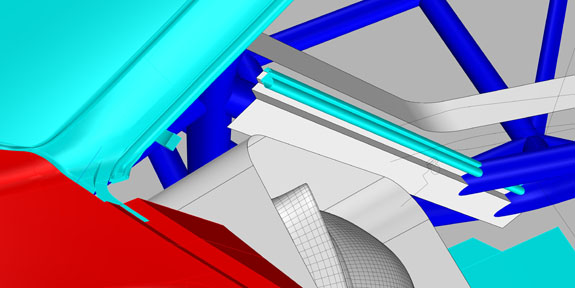

12/13/21 The detail work on every design is both frustrating and rewarding. The frustration part is that there is just so much of it. So many details. And every now and then, small details require big changes to resolve. All part of the process. The rewarding part is the realization that every step takes me closer to the vision that has resided in my head for so long finally becoming tangible reality. Having been through this a few dozen times, it doesn't get old. In fact it only gets better, because each new design is informed by all that came before. Some of the smaller details are finalizing the chassis tubing and, simultaneously, the bodywork details. Detailing the chassis involves verifying placement of every tube, down to the vent holes that prevent hot air from blowing out the welds during construction. Interference checks are run to make sure all tubes are trimmed properly, and corrections are made as needed. The finished CAD files will be sent to VR3 Engineering who will cut and bend the tubes. The accuracy of their process has been truly impressive and consistent over the dozen years we've been working with them.

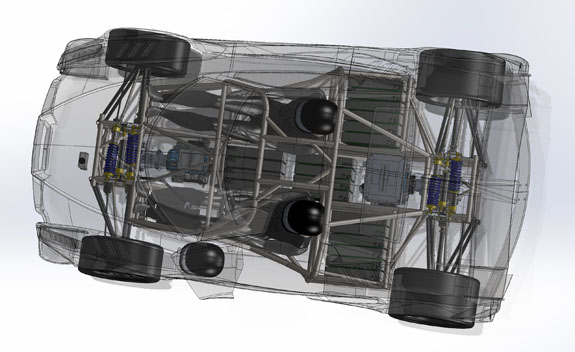

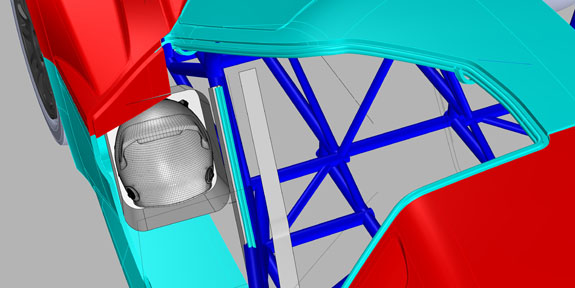

At this, near-final, stage there are 137 tubes with 86 unique shapes (some are duplicates). Every shape has a part number and its own CAD file. Total weight is about 220 lbs. With the requisite brackets and tabs the chassis will be about 250 lbs - nearly 100 lbs less than the D2. A neat detail, inspired by Lancia Stratos, is room for storage of two helmets. This is primarily a track car, so having room to bring a couple helmets is a plus (the Stratos had pockets in the doors for that, this is a modern take on it).

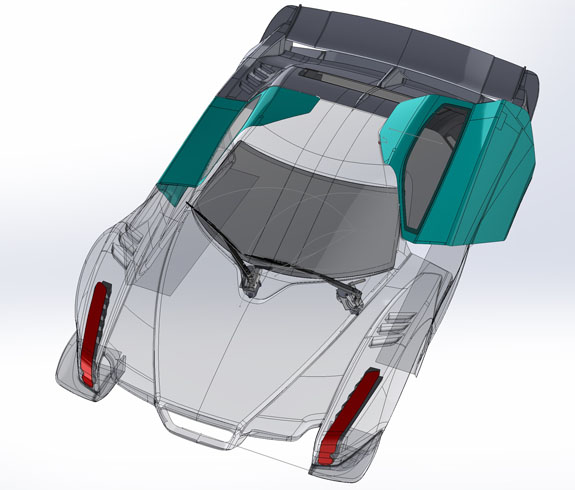

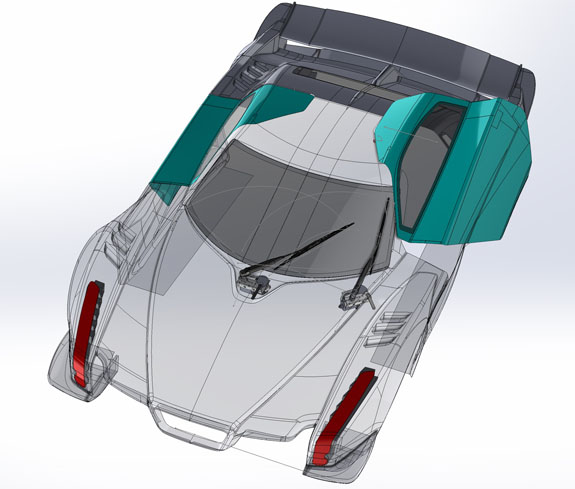

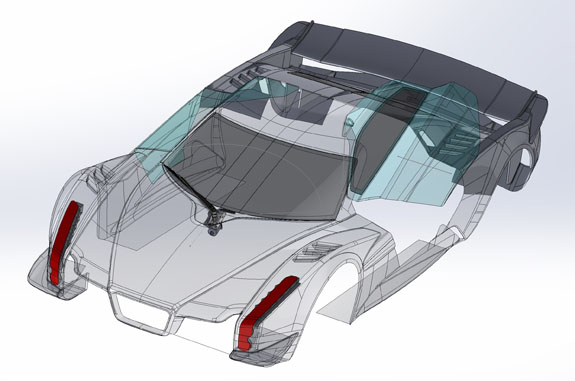

The multicolored screenshots above are from Michael Young, who has been working with me on the styling and is now taking care of the details like door seals, hinges, latches, and so on. This draws directly on our D2 experience as well as his work on other projects. Another detail is the windshield wiper setup. I briefly considered a two-blade approach, due to the highly curved windshield, but ultimately settled on a single centrally mounted blade. There is some concern about blade contact with corners, but if they made it work on the Stratos in '74, hopefully I can make it work fifty years later.

And of course the ModBatt battery tech is moving forward as well. In the last 12 months I have written and filed seven patent applications on everything from module construction to BMS architecture to blockchain-based tracking and control of modules and vehicles. Which brings me to the last bit of news. A couple of the patent applications have to do with controllably linking NFTs (non-fungible tokens) with computer-controlled devices like cars and battery modules. Currently, NFTs are being associated with things like artwork - both digital and physical. Problem is, if someone breaks into your house and steals the physical artwork, or takes a screenshot of your digital art, owning the NFT to it is of little help. Not so with computer-controlled devices. If they are linked to the NFT through my patent-pending methods, the owner of the NFT can prevent the car from being driven with a couple clicks.This goes beyond cars of course, but a car is what we're currently building. And no, it won't turn off the car while it's driving, but once the car stops it won't drive again until re-authorized through the NFT. So, each D8 will have an NFT associated with it. The owner of the NFT will own (and control) the car, and vice versa. This is actually a cornerstone of the ModBatt architecture. There are many more aspects to it, this is just a start. Also, I've decided that the production run of the D8 will be limited to just 8 cars total. These cars are the ultimate form of self-expression to me, the result of many simultaneous creative processes and a lifetime of cumulative experience coming together just so. I don't want to just 'turn the crank'. When these eight are built and delivered, I will go create the next thing, whatever that may be. If you find this site useful or interesting, consider supporting it with a paypal donation in the amount of your choosing to dp@dpcars.net

|