|

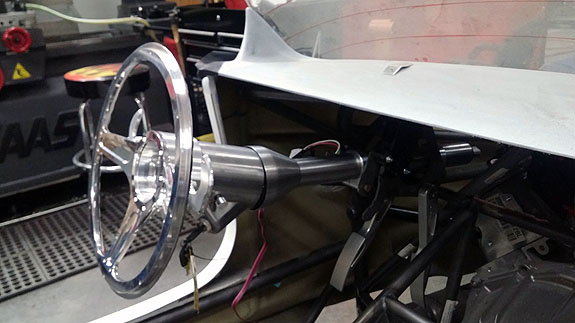

10/27/15 Just a quick update. The steering column mounts did get machined.

The controls package is starting to come together. It still needs a bit of tweaking, and of course actual seats need to be mounted in the chassis before we can decide if it works, but progress is being made.

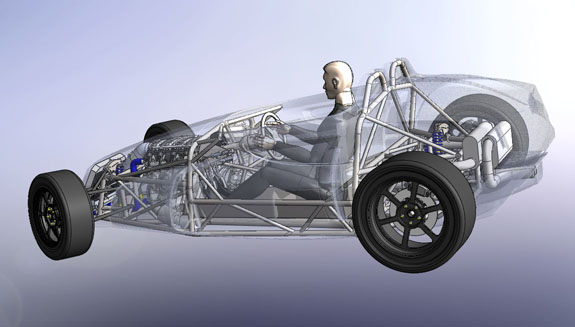

In the meantime we learned a few new things from additional D2 testing this past weekend (yes, still learning after nearly 4 years of development!) All that is going to be applied to the Stiletto as well. It's going to be a pretty cool machine when all is done. 11/02/15 CAD will get you pretty close (especially after models have been tested and refined), but when it comes to ergonomics there's still no substitute for trying it on for size in real life. And in order to do that, one must make something to try. So it's a bit of a chicken-and-egg which leads to an iterative process. Now that we have a first cut of steering and pedals in place, the next thing is to make a temporary floor out of a scrap piece of plywood, and try to sit in it.

Turns out the steering wheel had to move up quite a ways and half inch to the right. As an example of how intertwined the packaging is, moving the steering wheel placed a U-joint in a spot where we could no longer plug a connector into the water temp sensor, so we had to swap the sensor to the other head. I expect there will be quite a bit more of this. For test fitting we just used some 2x4s to mock up what the seat location would be. The actual seat is going to be fairly upright and there are limitations on size. I was able to find something that should work and fit with the overall character of the car. A pair of seats has been ordered, we'll see how well it all works when they show up. Another item that we're redoing, now that we've had some time to look at it, is the exhaust routing around the suspension. We're moving the pipes farther away from suspension arms, and from the gas tank too.

The floor is already raised to give 1.5" clearance to the pipes and allow room for additional shielding, if (when) it is needed. The real floor will be aluminum of course. Putting the car up on the lift allows more room to work on it, and a different view.

Work is also progressing in CAD on things like firewall, interior paneling, and the fuel tank. We couldn't find a tank that fits right so we're going to make it - just as well, since this gives us the opportunity to install reasonable baffling, which isn't normally present in tanks you buy off the shelf. Yes, it's a hotrod, but it will handle like a Palatov and therefore needs something to keep fuel from just sloshing around. It's gratifying to see this project moving along. Looking forward to driving it. 11/10/15 Got the seats. Looks like they will work. The Stiletto is a fairly compact package so I had to look for seats to match but which would allow a range of drivers to fit. What I found is 'Bomber' style aluminum shallow buckets. They are very comfortable, light, strong, and they fit. The stock covers are OK but down the line we can do custom upholstery. Getting it drivable is the first priortity of course. Right now the driver's seat is just in there on blocks. After a few more test fits and tweaks, making the real floor, panels, and seat sliders is next.

Fuel tank is coming along, door hinges and latches are in the queue. Quite a few details still to work out but we're knocking them down. 12/04/15 Continuing to work through all the details. There are lots of them - for example, the routing of the cooling lines requires that a spacer be made for the thermostat housing, in order to clear the belts.

There are also custom alternator brackets and a lot of other things. Like figuring out the wiring harness, or more specifically how to mate the GM engine harness to the aftermarket transmission controller and then to the rest of the car.

As in any car, everything is connected to everything else, and the tight packaging of the Stiletto means that we have to pay close attention to many systems at once. It's no different than our other cars in that regard so this is not unexpected, but the work still has to be done. 12/23/15 I had mentioned earlier that the entire project is for sale. So I thought I'd expand on what that entails. The car that we're building right now is obviously included. But also full manufacturing rights, including CAD, molds, bodywork pattern, and technical support to get going. The pattern was damaged slightly when the molds were pulled (this is typical) but it's handy to have if some modifications are contemplated down the road. Some are easiest by altering the first article body and taking new molds, as we've done with the windshield, but conceivably some could be done by modifying the main pattern and pulling new molds from that.

We can supply parts, do some or all of the manufacturing intially, or long term. There is a lot of flexibility, including possibility of changes to make it your own. E-mail me for more info.

Site Sponsors and Links:

|