|

11/21/14 The work on the windshield continues. The supports are still evolving and I have a couple thoughts on the retaining mechanism. This is just an in-progress update to illustrate the steps.

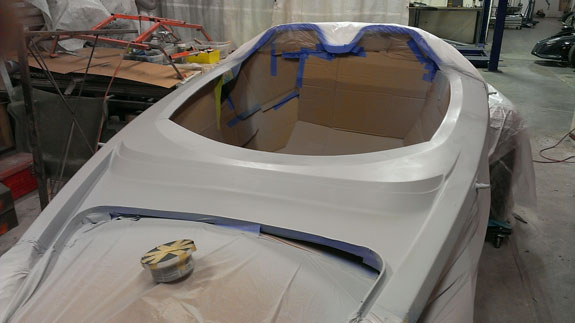

12/5/14 Some more progress on the cowl/windshield area. The windshield support shape has been finalized and the area is prepped for molding. Since everything is built up as a mixture of aluminum, fiberglass and bondo we're going to take a mold of the modified shapes, then cut out the temporary build up, make a replacement part in the mold and then bond it into the existing bodywork. This will ensure that the new area is as strong as the rest of the body and won't crack from vibration on the road. The mold will also be used to make 'splices' for initial production bodies until we can create updated tooling. Yes, Stiletto will be offered for sale as a kit with third-party assembly options like the D2, at similar pricing. We are going to be making the chassis and the rest of production details are still being worked out. Contact me for details.

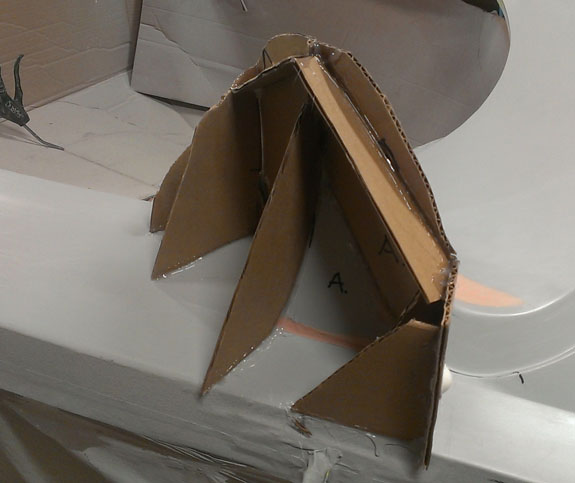

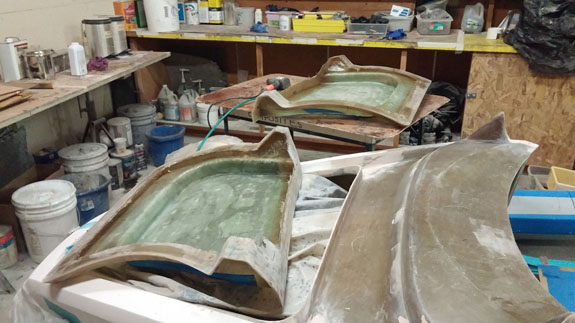

Mold is going to be in three pieces to make sure the part comes out cleanly. First, the fences are built up with indexing features that will ensure proper alignment on the mold sections.

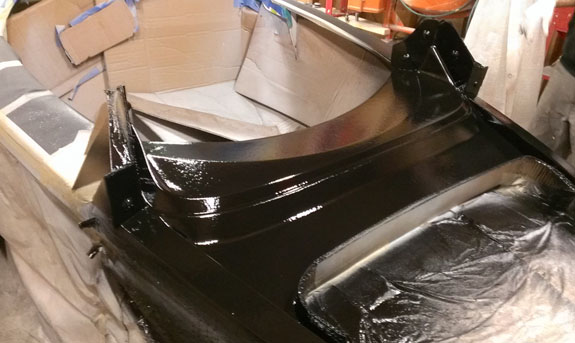

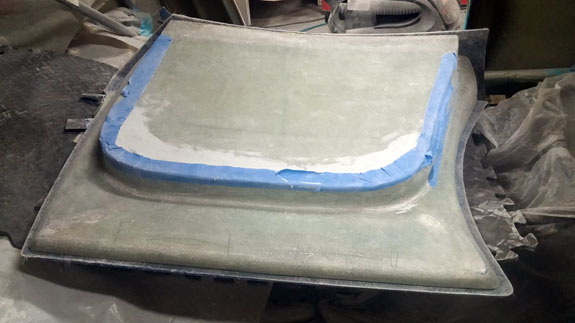

Next the center section is waxed, sprayed with gelcoat and the mold is laid up. After that the fences are removed and the end pieces of the mold are laid up against the center.

After the mold is fully cured it is removed, cleaned and trimmed. Then the temporary buildup is cut out (I always cringe when destroying plugs, knowing how much work went into making them, but it's all part of the process).

Part layup is next. 01/17/15 The updates haven't quite been keeping up with the work lately, so here's a chance to catch up. The cowl part is now made and has been spliced into the bodywork.

Next are the doors. The challenge is to trim the inner skins to fit the outers, then build up flanges for later bonding while keeping everything aligned and not allowing it to twist. There are quite a few steps to this process.

Once this is all done I'll get going on the hinges. Have been spinning them in the in-head 3D simulator in the meantime. It'll be a bit of a challenge due to the shapes involved but looks doable. And good practice for the upcoming D2 door project. Related to bodywork, since the rear wheels were too close to the fiberglass we went ahead and made a new set of longer rear suspension arms. They're now powdercoated and fully assembled and will be installed when the messier parts of the bodywork are done. 01/28/15 On the D4 page I mentioned there is Stiletto progress so here it is. The longer rear suspension arms are now on and there's clearance to the bodywork. May not seem like much of a difference but functionally it's between not working and working.

Could we have done it with just a spacer? Probably, but then there are other issues with bearings, stud length and so on. The more important point is that I'd rather just do it the right way. Cowl and door skins are now sanded, primed and ready for the next steps (such as door and hood hinges).

Overal the car is starting to look more and more finished. Simultaneously we're digging into the wiring for the engine, transmission and other systems. Also I like how the windshield has turned out.

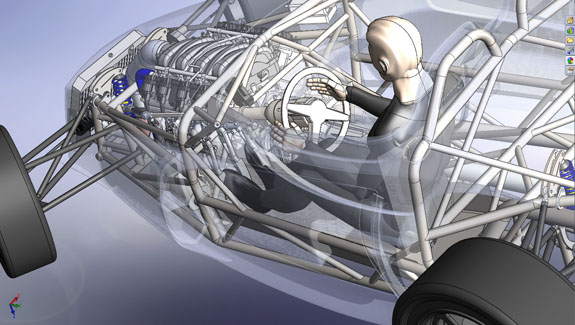

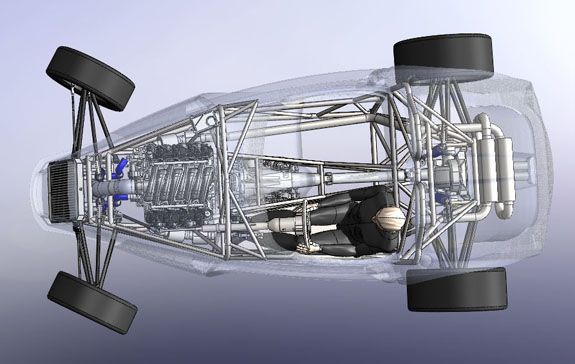

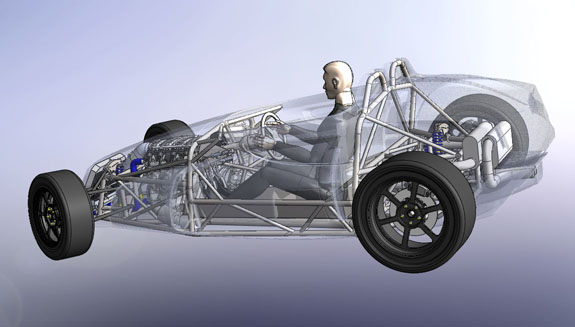

Lots of work remains (interior being not the least of it) but the progress feels good. It's also an ongoing learning experience, as always. It's getting there. In the meantime anyone interested in owning a Stiletto can email me for details. 04/20/15 Among all the other projects, Stiletto is moving forward as well. Right now it's all about the subsystems - plumbing, wiring, etc. The custom radiator is made and installed. Fits well. In the meantime I've realized that we've always taken pictures of the car in close confines of the shop and I was curious to see what it looks like out in the open. So we rolled it out in the street. Pretty cool, as it turns out :) Pix below (Tristan is included for scale). Yes, it's a 430hp, 1,900 lb car like the D2 and shares much of its chassis DNA.

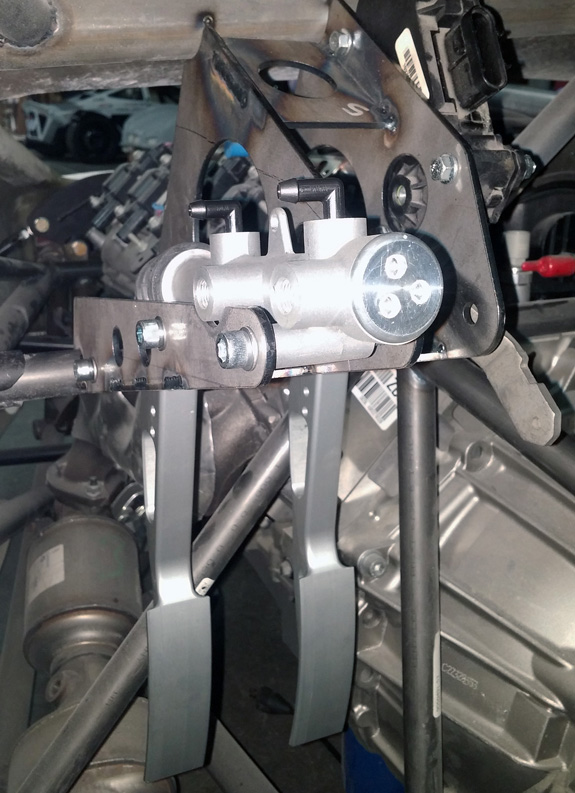

09/22/15 More Stiletto progress. This is the part where all the details and tolerances get worked out and practical solutions to the various packaging challenges are developed. Obviously we want to use as much D2 technology and parts as practical, but some things just have to be unique to the car in order to work. One example is the pedal arrangement. The seating position in the Stiletto is more upright than in the D2 and the cockpit layout is different. As much as I would have liked to use D2 pedal set as-is, the best solution here is to use a top-pivot setup. Especially considering that this car is an automatic, although I want to make sure manuals can be accommodated with the same design. Steering is also a challenge as it needs to be routed around the engine while not exceeding the max operating angle of the U-joints. After many attempted packaging solutions that ultimately didn't pan out, I finally came up with a combination that should work.

The pedals themselves are same as in the D2 but all the mounting structure and linkages are quite different. The next step is to fabricate all the pieces and test them. But first, a quick reality check to make sure the steering wheel clears the door side panel in its intended position.

Looks good so far. The steering intermediate shafts are already fabricated, now we need to fabricate and weld the mounting brackets in place. More soon. 10/15/15 The laser-cut brackets are here so it's time to install them and test-fit the pedals. I still have to machine mounting collars for the steering column, that will happen in the next couple days.

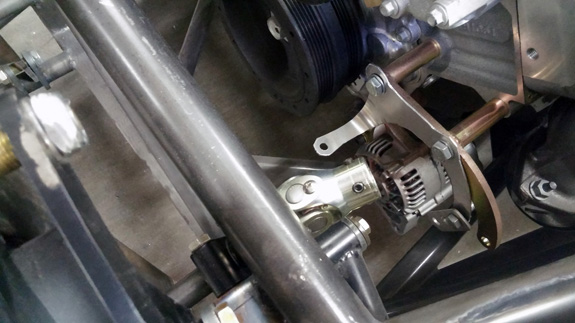

Other brackets being worked out are alternator mounts (not final yet) and all the interior paneling.

As we push towards completion, both this car and the entire project (including tooling, CAD and manufacturing rights) are now available for puchase. Email me for details. Site Sponsors and Links:

|