|

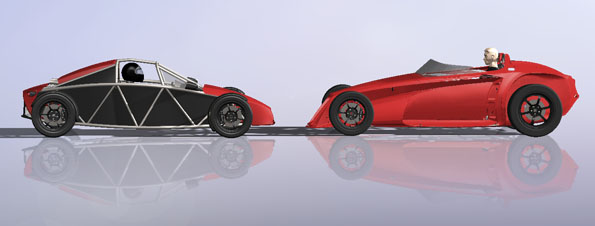

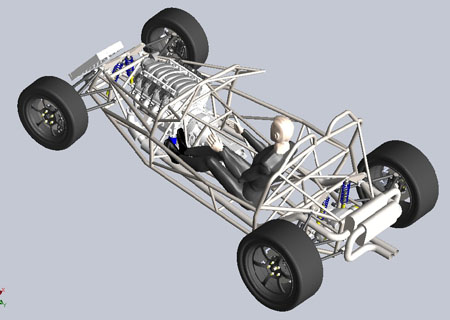

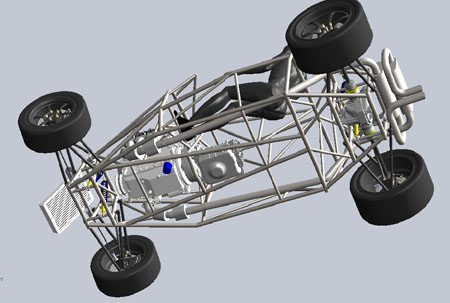

08/12/11 I've occasionally mentioned customer projects I'm working on. One of these is the Stiletto Roadster - it is the brainchild of Al Denk and done in cooperation with Contactscale. I joined the project when styling was already decided and it has been an interesting challenge to package chassis, occupants and mechanicals into a styling exercise. Once the first car is built, tested and refined we will be building the rolling chassis. The premise behind the car is a modern hotrod - inspired by the traditional Rod/Custom styling and powered by a GM LS3 V8 but with a sophisticated chassis that can actually use the power in more than just a straight line. With 430hp pushing roughly 1,600 lbs I think it's a nice thing to have :) And yes, I'm aware of the Factory Five coupe. Theirs is a nice design and an improvement on the cookie cutter ladder frames that dominate the field, but it still uses a live axle in the back and the front is a fairly straightforward cantilevered setup. The Stiletto goes several steps further with a full chromoly space frame and independent pushrod-operated suspension at all four corners.

The Stiletto is closely related to the D2 in terms of frame and suspension technology, although the only parts the two cars directly share are uprights and engine. Each car has a unique mission which drives its design. For example the wheel and tire sizes on the Stiletto were chosen for styling reasons to stay true to the Hot Rod genre whereas on the D2 they are selected for optimal performance.

As a reference for size, the D2 is the same length and height as an Elise, the Stiletto is about 10" longer and the seating position is much more upright (no the rollhoops would not meet SCCA regulations but they're better than not having anything). The design and first prototype of this car is actually pretty far along, as the progress pictures below demonstrate. After the frame design was complete the build started with a tube kit like all our other cars.

The suspension is the first application of the GTS uprights, the 'street' version of the GT design but using balljoints instead of rodends. It uses inboard Bilstein shocks and coilover springs all around.

A lot more progress is coming soon, with the goal of having the car on its wheels by the end of September. Depending on how development goes production cars are targeted for Spring of 2012. 09/30/11 I spent the day down in San Jose visiting Contactscale. The purpose of the visit was to discuss the progress on the bodywork, compare/transfer files and dimensions, make some decisions on interior, doors, windshield, exhaust and so on. We did all that.

The body shape looks cool in person. Very compact - remember there's going to be a 430hp V8 in there. My kind of car! :) As I mentioned earlier I did not do the styling on this car but it does kind of tie in with my own while still standing apart. Did it influence the recent D2 design changes? Not directly and not consciously but now that I look at the pictures there are definitely shared themes. Make of it what you will.

And yes, there will be doors. The precise details of where the cuts are and how they open was the subject of some discussions. And yes, there will be a stout tube inside the door that will serve as shoulder-level anti-intrusion beam when closed (it will tie the hinges and the latch together structurally). Another detail that got worked out was exhaust routing, shown below. The catalysts upfront come as part of the GM E-Rod LS3 kit.

Yes, the exhaust will be properly shielded and no, interior heat will not be an issue when all is done. Most production cars run exhausts under the floor (but there will probably still be comments on some forum somewhere ;). Ditto for radiator size, which based on previous experience with the Atom (similar power output) is perfectly adequate IF configured right, especially since this is not a track car. Anyway, much progress but much more to go. 10/19/11 Lots of progress on all fronts and that includes the Stiletto. We now have the braking system finalized, the drive axles are made and ready to be installed, and a lot of detail design is either done or nearly so.

The rear brakes use Wilwood's integrated calipers which have a mechanical parking brake built in. The rotors are 12.2" diameter vented units. The Stiletto website is evolving as well although like the car itself it's still a work in progress. Keep in mind that the renderings on those pages were the original concepts, before any actual design work with real-world dimensions began. So while the car will look generally like that, it won't be EXACTLY as depicted. Wheels, especially!

The real wheels are neither small nor narrow (use the bicycle or the D4 wheel for scale) but they are still tiny relative to the reality-unconstrained concepts. Top drawing is to scale, bottom one is concept. The actual rear tires are 295/45-20 and are about 30" overall diameter. I don't know what the supposed size was in the lower drawing.

I think the Stiletto is going to look good when all is done and on a hotrod I actually prefer a somewhat taller sidewall, but this illustrates one of the bigger challenges in making a real car. It's easy to make a car look 'exciting' with 35" rubberband tires and other dramatic features. Then the designer walks away and production people pick it up and try to make it work. If whoever is doing that work has an artistic eye the result can still come out OK but ideally a design would be an iterative process with communication back and forth. That's why normally I prefer doing both the esthetics and the structure myself. Makes for very short design meetings :)

|