|

March 21, 2012 The various internal engine bits are here. We're taking them up to Seattle to GDRE this weekend, along with the engine itself, to get the buildup started.

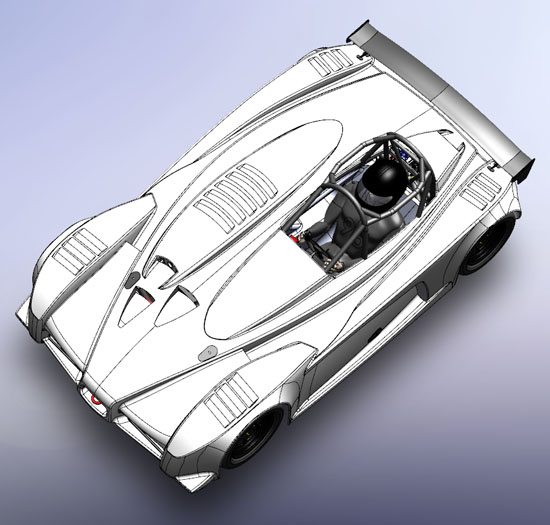

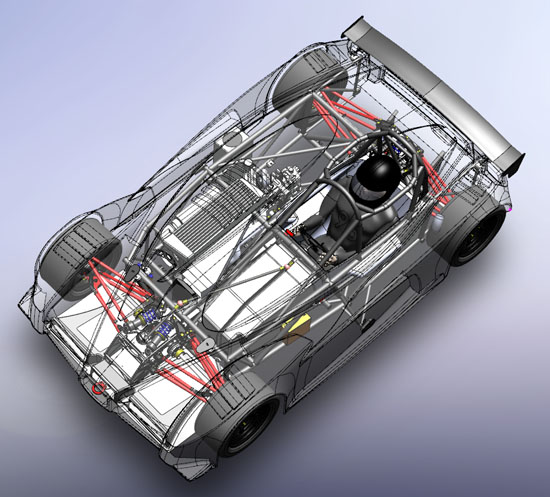

The turbo is on order and I'm working on all the manifolding in CAD. In the meantime, Tristan is making progress in putting the frame together. The ingress/egress has been a question up till now. It's one thing to have it all in the computer, quite another in real world. Thankfully it all goes together exactly as planned and Tristan has personally confirmed that not only can he get in and out through the top (the default way) but also through both sides and front. This puts to rest any concerns we may have had in that regard.

Much is done, much is still left to do. Overall pretty happy with progress so far. The clock is ticking though and we all hear it loud and clear. March 31, 2012 Last weekend the engine and its future parts got dropped off at GDRE. Another challenge is simulating the altitude. At the finish line the ambient pressure is 6 psi lower than at sea level. May not seem like much and the first thought was to try and use the dyno chamber's exhaust fan to drop the pressure. However I know that air pressure can produce amazing forces. So a quick calculation - the sturdy steel dyno chamber has a safety glass window. The window is about 50" square. That's 2,500 square inches. Times 6 pounds for every inch and that's 15,000 pounds pushing just on the window. Can you park a semi truck on the glass? Doubtful. So another plan is needed. I have a couple... We'll see what ends up working best but it's a safe bet it'll take a couple tries. In the meantime steady progress continues. The frame welding is pretty far along.

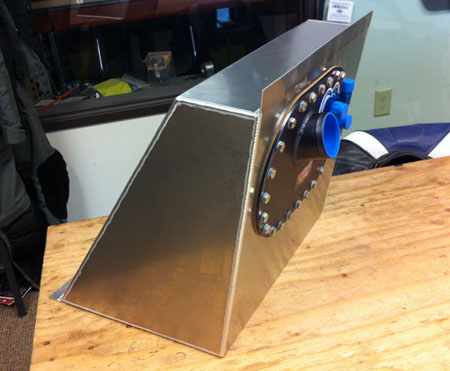

There are a couple hundred welds in the thing, some quite tricky. It takes a bit of time. Other parts are coming in as well. The FuelSafe fuel cell is here. It has a full rubber bladder and a high-pressure fuel pump inside the aluminum enclosure. Capacity is 7 gallons, just enough to get us to the top.

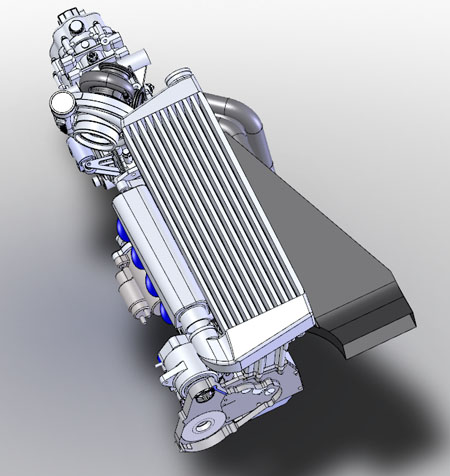

Intercooler showed up recently as well. It's quite large and one might wonder where it's going to go in the car - never fear, I already have a good spot for it and it's actually going to be pretty clean. One surprise is how heavy it is - about 18 pounds. Looking inside shows why. It being an air-to-air heat exchanger, both the inside air and the outside air need equal surface area for best efficiency. This means that all the fins you see on the outside are replicated on the inside, internal to the 'tubes' the compressed air flows through. It's a lot of aluminum. The bet is that its efficiency will more than offset the weight. We'll see.

The weather here is still thoroughly lousy but one can only hope it will get better. Soon. When that happens we will start aero testing, using the D1 at first until the D4PPS is fully drivable. To that end the D1 is being put back together. Aside from a few system upgrades which will take a little tinkering, it is nearly ready. Timing everything just right is going to be quite a feat!

The race is still 3 months and one week away but I feel like we're up against the deadline in a few days. Which isn't far from reality (there are just 98 days left) - we have to have things ready soon in order to have enough time to sort them out. The mountain is formidable and so is the competition. We have our work cut out for us! Of course I have several layers of contingencies and plans B through X, give or take, but the challenge and the pressure are very much there. I'm really eager to hit the track and start testing. April 18, 2012 Progress is good but we're definitely feeling the deadlines looming. The engine is back from GDRE with all the new internals. The turbo is complete and is about to ship to us. The shocks have been custom valved by Shock Shop and are the final piece of suspension that we were waiting for, the rest is here already and will be all together shortly. They are Ohlins units which have been set up and dyno tested by Chris Billings specifically for the car. We've sourced our shocks and custom valving from Chris for several years and have been very impressed with the results. Chris is one of the very few people out there who truly understands what shocks do on a race car. It's not as straightforward as one might think and there's a huge difference between merely tweaking the adjusters and properly setting up the internal shim stacks to obtain the desired characteristics. There's skill in the setup but the real trick is figuring out what characteristics are desired in the first place.

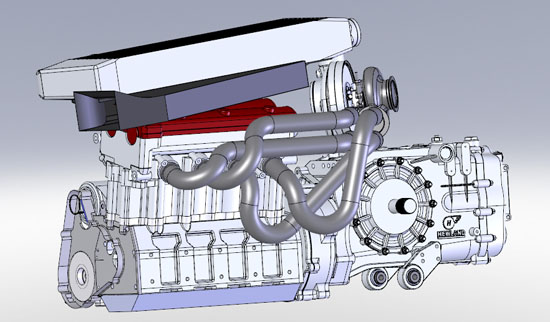

The next couple weeks will be very hectic. There is a lot of work ahead on the various subsystems, fabrication of all the custom pieces and the integration of all the parts into the car. It's a good thing we have the CNC machine inhouse - there's a lot of unique machined components. A lot of material has already been ordered and programming has started for the parts. As with all our cars this one will be put together with the bare unpainted frame, driven a few times, then torn down, painted/updated and put together again. We're planning to do a timelapse of the final assembly. In the meantime, now that the weather is starting to look more promising, testing will start Friday using the D1 which has nearly identical chassis, bodywork and aero. We'll be running primarily at ORP. This is where we'll start getting videos on the blog so it should be fun. April 28, 2012 Only 10 days since the last update but seems like it's been a month. Lots of things happening. The most important is that we've started testing using the D1 chassis. Since the D4 PPS shares the basic layout, chassis and bodywork/aero with the D1 (and has a similar power output) we can accomplish a lot of testing with the D1 that is directly transferrable to the Pikes Peak car. We've posted a video of a typical test lap. At the same time the actual D4 PPS chassis is being assembled. While that is happening I'm nearly done with the intake and exhaust design and some of the parts are already here.

One of the things we've already confirmed through testing is that this engine is going to need a lot of airflow. To that end we're adding new ducts in the bodywork - in addition to the standard intake scoop there is also one to feed the large intercooler and another to keep the air moving around the engine bay.

The next four weeks are going to be a very intense mix of fabrication, design refinement and testing. So far the results are encouraging... May 6, 2012 Thought I'd post some of the in-progress chassis assembly pictures from the past few days...

For the moment we've got the D4PPS shocks/springs on the D1 so the D1 units are temporarily on this chassis. Our next test with the D1 is in two days - the goals are to test and tune suspension setup, brakes, aero and some heat management strategies. We've made some adjustments to the Geartronics paddle shifter and we'll test that also. We really like the system on the D1 so we're getting one for the D4PPS as well - the ultra-fast shifts will help keep the turbo on the boost and let David focus better on driving the course. The turbo itself is here also. It's a custom configured Garrett Motorsports unit that has much wider operating range than Garrett's standard aftermarket turbos. The compressor and turbine are sized specifically for our application.

Exhaust parts are on their way from Burns Stainless, which will be the last major bit of fabrication that should happen next week. The last major purchased component - the custom gearbox - is due to ship from Hewland on the 16th. Yes, it's cutting it close and we have the contingency of borrowing the D1 box for the June testing. The D1 unit is not ideally geared for the mountain but will get us started. The whole bolting-it-together-as-it's-loaded-on-the-truck is a very common theme in racing (we built the dp1/e in the paddock at Laguna two years ago and I keep hearing similar stories from others). This is why we're treating the June test as the deadline and not the race itself! As of right now it's looking like we'll have a week to do final assembly and test on the car before we take off for Colorado on June 4th or 5th. In the meantime, having the D1 up and running will really help us get the basics sorted so that when the gearbox shows up we can focus almost exclusively on engine tuning. I expect in June we'll have only a preliminary configuration. We will definitely learn a lot from the test on the mountain which will help us finalize the setup for the race itself. We're still two months from that and we're all very stressed already :) That's what we signed up for, however, and it is certainly quite exciting. In a good way. Another quick item - the first shipment of the Simraceway SRW-1 wheels is on its way to us so our 'Blue Sky' level and above sponsors will be getting the wheels shortly after we receive them. Our most sincere thanks to all of you for your support - quite literally we couldn't be doing this without you!

|