|

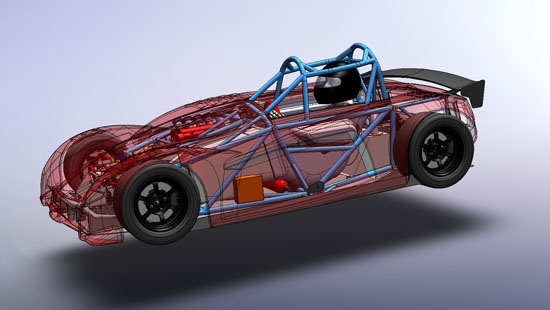

February 5, 2012 (Updated February 6) A bit of further and more detailed review of the rules, some conversations, and the result - an updated rollbar structure. I've been trying to come up with something that doesn't totally butcher the looks of the car and, to me at least, this one is fairly pleasing.

Again still not official but more likely to become so. All part of the process. UPDATE 2/6/2012: Some additional challenges - we tried listing the car on eBay but they promptly pulled the listing because the delivery date is too far out. Perhaps I will rephrase the listing and clarify that what we're 'selling' is a sponsorship, the fact that the sponsor gets to keep the car after the race is just part of the package. More stuff to deal with... In the meantime, if you know of anyone who'd like to own a Pikes Peak Unlimited car for a mere $75K send them our way! February 7, 2012 A nice milestone - after some revisions (mainly beefing up the side structure) the proposed rollcage and frame design has received the official OK so we're going to go forward with construction.

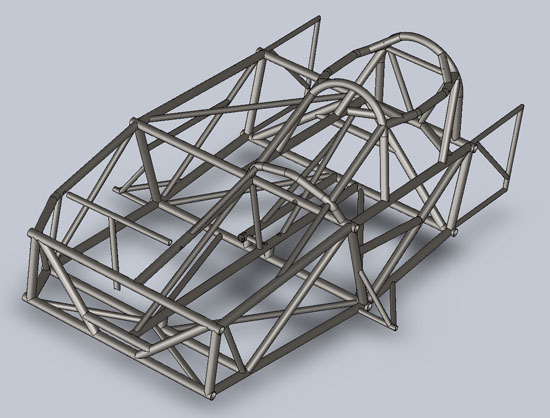

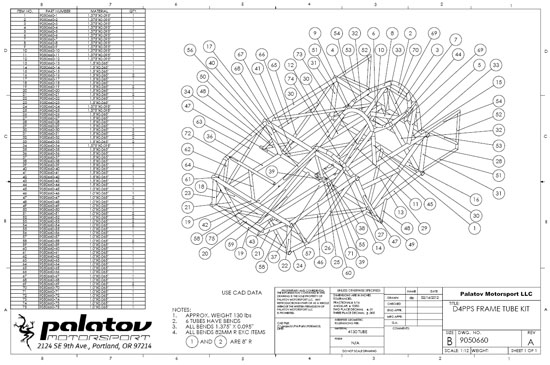

The weight penalty vs the standard car is only 20 lbs overall, including rollcage and other reinforcements. For people intending on using our cars in hillclimbs (rocks, trees, cliffs) the beefed-up structure is a good option and we will offer it as a regular production item. First order of business is to generate the detailed CAD files for each tube that's different from the racetrack frame and then we can order the tube set. Our goal is to have something put together that starts resembling a car about a month from now. So far we're right on schedule with the timeline but it will take some considerable effort to keep it so. We're committed to doing what it takes. February 16, 2012 Things are moving forward. The detailed frame design is done, now it's off to be made. There are 100 separate tubes and each one needs to be individually documented. About 130 lbs total weight, not too bad considering the beefy structure.

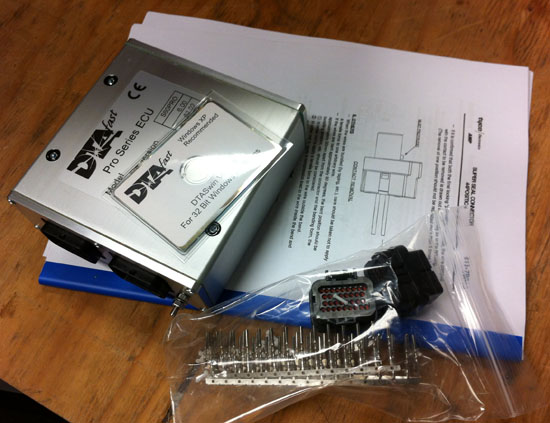

A lot of items have been ordered and some have been received. The real tangible progress will start in about a month. In the meantime we're going to have some fun announcements coming up. Stay tuned! February 26, 2012 The mountain offers many challenges and a major one is altitude. At the top, at 14,000 feet, the air pressure is only a little more than half what it is at sea level. It's hard to breathe - for both the driver and the engine. David has driven the course many times and knows what needs to be done on the driver side of the equation. For the engine, I have to figure it out. Obviously we are going to use forced induction. But how the system has to be configured for optimum perfomance is not quite so obvious. The altitude and the small displacement mean that to get our target power numbers we'll need a pressure ratio of around 4 (approximately 24psi boost), at 40-50 lbs/min corrected airflow. If we were only interested in top end power that wouldn't be too difficult with modern turbos. Boost would come in (with a bang) at about 5K rpm and give us usable range of 6K-10K to work with. Great if the whole course were high speed but there are many tight switchbacks and getting a good (and controllable) drive out of them is very important. So for the last week or so we've been running some simulations with calculated torque curves and actually 'driving' them on a virtual Pikes Peak course. There's much more of this to be done but so far the results have been very educational. The main conclusion is that we will most likely need to go with a twin-turbo setup of some form, to give us both the low and the high end that we need. At the moment everything is on the table - variable vanes, twin-scroll housings, parallel, sequential and staged setups. I'm learning a lot (the BMW 535d setup is quite interesting for example) and starting to come up with ideas of my own... If we were running at sea level none of this would be necessary. But I have to say I rather enjoy the challenge :) A big part of making the whole system work is controlling it. For that, we've just purchased a S60Pro ECU from DTA. It has a lot of flexibility and even provides a sophisticated ALS (anti-lag system) which we could use as a fallback. But, as the DTA manual explicitly says, you need to have a big racing budget to run ALS because it creates super-high exhaust temperatures and greatly shortens the life of many expensive components. I consider this a last resort but it's good to have contingencies.

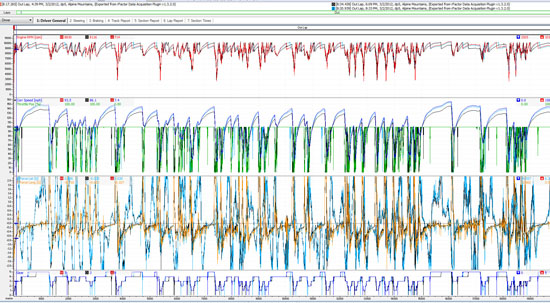

I've used the bigger S80 DTA computer on the D1 (and on the V8 Atom before that) so I'm familiar with the product and how to set it up and tune it. It's good to have some known things in the mix :) We will start assembling the suspension this coming week and welding the frame shortly after that. There are some things I need to do for the engine (design/machine different endplates and bellhousing to mate it to the gearbox) and of course have to design and build all the plumbing and valving for exhaust/intake/turbo setup. We'll be using a large intercooler and it's scheduled to arrive in the next couple days. Once that's here I can get it in CAD and start on the packaging in earnest. March 3, 2012 Over the years I have found that computer simulation is a very valuable development tool, when used properly. This includes CFD, FEA and in this case Driver-In-The-Loop simulation (DIL). Basically DIL simulation is what people think of as video games but there is a difference. While console and arcade games actually have a lot of very sophisticated computing at work, their design criteria are fun and player engagement. Therefore accuracy is deliberately sacrificed for entertainment (think Hollywood). But there is a class of programs out there which are generally referred to as 'racing sims' that harness the power of today's PCs to deliver a good deal of accuracy. Yes, this makes them harder to master and at times more work than fun but for the dedicated enthusiast (or racer) there is a lot of value in it. So in this post I want to talk a bit about simulation and how we're using it. But first, some background. Whenever doing simulation of any kind you have to accept that the simulation is just that - it is not reality and is only useful for development purposes when the limitations and assumptions are understood and accounted for. It is very tempting when the computer spits out a number such as a particular lap time to take it as fact. Afterall, look at all those decimal points... But one has to look beyond the numbers and put them in context. There are many aspects of it and I'll only touch on a couple of them here. One way to look at a sim is a series of very complex real-time engineering calculations. It is common engineering practice to calculate loads and forces for a given static condition. A sim does this literally billions of times a second for every inch along the track, and it does what no traditional engineering calculation could - take actual human driver input as part of the equations. When looked at in this light the value is quite obvious. There is even a way to keep track of all the data and analyze a test 'run' in detail that only F1-level teams with annual budgets in tens or hundreds of millions have access to in real life. The catch of course is that it isn't real, so all data gathered must be interpreted carefully. One specific example is our effort to select a turbo configuration for the car. We have a reasonably accurate version of the paved Pikes Peak track in the sim (will have a much better one later, more on that when the time comes). We also have our car's physics loaded and we've gotten some calculated torque curves from a turbo expert at Garrett Motorsports based on our specific parameters. Using all of this we did several virtual test runs up the mountain with different turbine and compressor configurations, to see what effect the various tradeoffs have on the overall time. A sample set of plots is below.

Yes, the picture is intentionally blurry and no I won't go into the specifics here - this is just an illustration of the kinds of data available. The traces from top to bottom are engine revs, speed, lat/long g load and gear selection. Lots of other parameters are avaialble too but of course to have any accuracy the input data has to be quite good. In this case we're just looking for trends and apples-to-apples tradeoffs. We can see what percentage of time the engine spends in various rev ranges, what gears are used and how often, what (theoretical) speeds are reached and so on. Then we have to make reality checks - just because the sim says the car will go through a corner at 140 mph, in real life the cliffs and potential for gravel may dictate otherwise. Overall so far the simulations have been very educational and we're close to finalizing the choices. I've already made changes to the gearing based on data from the sim. While on the subject of sims, here are a couple more thoughts that are not directly related to the current stage of development but are good to keep in mind: A sim can teach you a lot about how you drive, paradoxically by depriving you of some senses - the 'seat of the pants'. There are some synthetic feedbacks being generated - sound, force feedback in the wheel and in some fancier rigs even motion. But one has to be careful because generally no feedback is better than bad feedback. Here's an example - let's say you put perfect earplugs in which blocked all the sound. You can adapt to that and after a bit use other senses to compensate. But now imagine that instead of earplugs you got headphones which pipe in sounds kind of related to what's going on around you but all wrong. There's no adapting to this except to tune it out and rely on other senses instead, but it's extra work. So how can a sim teach you? The most important thing to realize is that high-performance driving is all about ANTICIPATING, PLANNING and EXECUTION rather than REACTING. Talented drivers do it intuitively, the rest of us have to do it consciously to be any good. Normally, seat-of-the-pants inputs provide you with feedback that let you know what's happening and help you REACT. Which, in an unknown environment, is very useful. But the key is that a track is a known environment, to go fast you have to have it all pre-programmed, preloaded and just click off queued tasks based on triggers such as brake markers and other reference points. If you're reacting you're too late. Soo... by depriving you of inputs that feed reactions a sim can force you to plan, anticipate and execute BEFORE things happen. It takes a bit of introspection and self-analysis (and treating a 'game' as work, which is counter-intuitive and not always fun) to benefit from this but it's well worth it. After gaining proficiency in the feedback-limited sim and jumping back into real life, the full benefit of live sensory feedback becomes clear - it is there to give you additional information about how your plan is progressing so you can employ some ready contingencies as needed. Because a real working plan is never static. It's a constantly moving target and contingencies are what lets you stay on it while inputs help you choose. You pitch the car into a corner intending for the back end to step out and then wait for it to happen so the next part of the plan (acceleration) can commence at just the right moment, already thinking several steps ahead. As opposed to going into a corner then being surprised by the back end stepping out and scrambling to react with all focus on just getting through it and no thought of what comes next. This of course applies to design just as much as it does to driving, and simulation can be equally helpful there. When used right. Our goal is to show up on the Mountain with a plan ready to execute and as many contingencies as we can manage. To that end we've teamed up with Simraceway - there are lots of synergies in what we're doing and I'm very excited about the potential of this relationship. More on that as things develop. March 16, 2012 There is a lot of progress on all fronts. The most visible is the frame itself - it's coming together quickly.

We now have CAD for the turbo and I'm designing the exhaust and intake manifolds. The fuel cell is being made, as is the gearbox. The remaining engine internals (pistons, rods and cylinder block) are on their way to us. Shocks have been received and are now being custom valved by Shock Shop. The rest of the suspension is already here and ready to be assembled. While all this is happening, last week we went down to California with the standard D4 to have Simraceway staff and a couple journalists drive it at Infineon raceway. The main objective was to compare the real-life D4 directly to the same car in the sim, on the same track. The links to the press coverage are on our Facebook page and more is coming. The significance of the trip to the Pikes Peak effort is that it helped correlate simulator to real life. In the hands of Nico Rondet, Simraceway's chief instructor, the standard D4 did 1:38 on the 12-turn configuration of the course which is pretty quick for a 175 hp machine and given that Nico only had half a dozen laps the car. Add another 200+ hp, AWD and better aero and you can get an idea for what the Pikes Peak car should be like. We want to get the most value out of simulation and understanding the extent of correlation is critical to making the best use of data. In plain words, we need to know which detail information we can rely on indepth and which can only be used as a general guide. Very pleased with the results so far and we'll continue working with Simraceway as the project moves forward. The weather is still unfriendly here but this will (hopefully) start changing over the next several weeks. When that happens we will run our first tests at ORP, initially with a standard D4 and then the D1. This will get David more familiar with the chassis and its characteristics and will get us a head start on the aero since it's very similar to the D1. This is where it gets fun :) |