|

January 7, 2012 The first official blog entry. Of course the big news is that thanks to very strong sponsor support so far we are going forward with the Quest. Our entry to PPIHC is in, with David Donner as the driver and a D4 as the car. But not just any D4. As fast as the standard car is at sea level, to take on the likes of Tajima and Millen at 9,000-14,000 feet of altitude we'll need more. Quite a bit more. There are three primary areas of modifications that are necessary to compete: chassis, powertrain and aerodynamics. In this entry I'll talk briefly about each, to be expanded on in detail as development unfolds over the coming months. Chassis: The primary driver behind chassis mods are the PPIHC safety regulations. These in turn come from the unique characteristics of the course - it is narrow, surrounded by sheer drops and rock walls. No runoff areas, sand traps or tire barriers here. Therefore the rollcage requirements are more stringent than you'd find at a normal racetrack. I have already posted a preliminary picture and have in fact shared the design with race organizers and gotten their initial approval. This is by no means final - the design will evolve and any final approval will be the result of a complete tech inspection of the car in person by PPIHC staff. The important thing for now is that I know what needs to be done, the direction has been set and the dialog has been started.

Powertrain: Currently we are facing some choices. The basic goal is to get over 300hp start to finish and preferably 400+. Combined with approximately 900 lb weight this will give us the power/weight ratio to run with the top competitors. There are several options here and the deciding factors are cost and risk. The lower-cost approach would be to go with a built Hayabusa, turbocharged and tweaked to the extent practical. Generally turbo 'busas are a known thing both in performance and cost. The concern is power delivery and ultimate power capacity - to get the necessary oomph there may be too much sacrifice in drivability, which would hurt us in tight corners. The tight stuff is exactly where we're trying to gain an advantage so it would be counter-productive. The other approach is to go with a Hartley H2 (basically half of the H1 V8 that's used in the D1) and the same Hewland gearbox that's in the D1. This powertrain would sit oriented north-south, like in the D1, as opposed to the transverse orientation of the 'busa. A turbo version of the H2 has shown as much as 650 hp so if we shoot for 400-450 we should have a lot of flexibility in tuning. The Hewland box is also a preferred solution to the stock 'busa. It has better strength, wide choice of ratios, a reverse gear and it eliminates the primary chain which would be rather stressed at this power level. Seems an easy choice? - Well it would be, except for cost. It would take approximatly an extra $25,000 to go the H2/Hewland route. That's additional money we would have to raise and soon. Below are some pictures of an early H2 (we don't currently own it) and the stock Hayabusa engine/gearbox setup. Weight is only about 30 lbs more for the complete H2 setup.

Aerodynamics: The rough estimate is that on the course we will lose about 30% of downforce vs sea level. There is much analysis to be done in terms of average corner speeds and the actual impact of aero on overall time. This is planned for the coming months. Also, we have a brand new aero configuration to test which we hope will be much better than what we had last season. The primary bet is that the new setup, with some appropriate tweaks, will work well enough to do the job. However as a contingency I have been evaluating some things we could do as a bolt-on 'fix' to get more downforce. It has to be something that we can easily install and remove so we can evaluate its effectiveness in June. Below is an early concept, naturally it will evolve. With luck I'll be able to improve on the looks somewhat, too :)

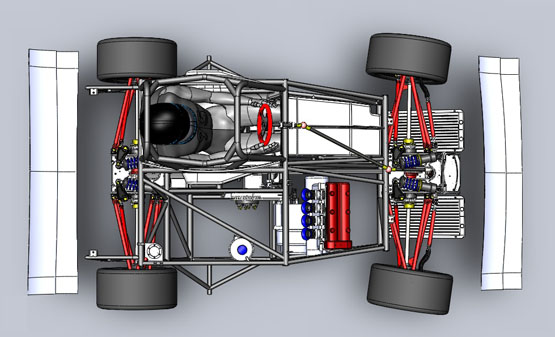

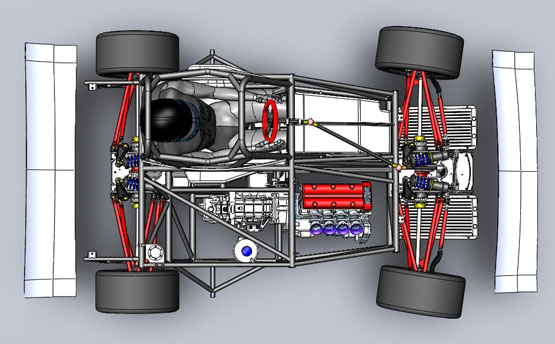

There is a lot of work and learning ahead. This is going to be fun! :) January 21, 2012 There is a lot of design and building activity on other projects but only a portion of the technical resources are going towards the Quest at the moment. Right now the primary focus for the Peak Quest is on fundraising because the available resources determine what we are going to do, when and how. So we are in the process of reaching out to potential commercial sponsors and looking at other sources as well. Even though we are a very lean operation, there is a cost associated with every choice. The choice of powertrain is the main one - I touched on it briefly in the previous post and will expand on a bit more here. But before I do, a clarification: I was asked earlier if my mention of fundraising is a request for current sponsors to increase their contributions. It isn't. We are very grateful for any and all support you've chosen to give us. I also want to make it clear that we are not asking for charity or handouts. Every one of our sponsors will receive something and we will work very hard to make sure that everyone, regardless of their level of contribution, will get their money's worth and more. The reason for bringing up finances is that this blog is about relaying our story, as it unfolds, and the issues and challenges we face. It just so happens that at this early stage the greatest issue and challenge is money. It is the lifeblood of any endeavor but when you read or watch a story about some quest, money is seldom mentioned - it "just happened" in the background and now magically the heroes charge forth to victory or at least fame and glory. I suppose it's not fun, or maybe considered in bad taste by some, to talk of finances. That's boring accountant stuff, let's see some race video! :) Well, the inconvenient truth is that without money there are no videos. As I always say "money is not everything, it's what you get everything with" :) Anyway, enough on the subject, I just wanted to explain. On to the more fun subject of drivetrains, transmissions and power. Let's start by saying that we are up against very experienced and skilled competitors running anything from 800hp to over 1,000hp. We do have the advantage of less than half their weight but at the end of the day, it's a looooong uphill run and needs to happen quickly. So the more power, the happier. The default choice, a turbo Hayabusa, is actually a sound one. 'Busas have been around for over a decade and much has been done with them. There are many drag bikes out there with over 500hp. The weak points are known and solutions exist to address them. If we go with a 'Busa, we'll be looking for at least 300hp at altitude and preferably 350+. The tradeoffs are primarily in drivability. For strength we'd have to keep displacement at 1,300cc (don't want to bore out the cylinders, it weakens them) so we'd have to pay close attention to engine management and overall system design to keep the turbo on boost. Since we are planning on using an electronic paddle shift it will help with both maintaining boost and making life easier for the gearbox. So while I would have concerns about the box in an endurance race, for a sub-10-minute run it should be fine. Of course the preferred solution is the Hartley H2 with a custom Hewland JFR, same box used in the D1. The H2 uses a Hayabusa top end but completely replaces everything below the cylinders with custom billet parts. The crank is 4340 billet and has not only longer throws (for bumping displacement to 1.5L while keeping piston bores stock) but also has larger journals for more stiffness and stronger rods. The case is drysumped by design (by contrast Hayabusa drysump is a bandaid), the engine sits lower in the chassis, and even allows more cooling airflow around it by sitting North/South. On the gearbox side the clutch is stronger, the box is stronger and has its own oiling system, and there is a wide choice of ratios. Even a reverse, not that it would matter for us. As a result of all the advantages we could readily expect an extra 100hp from the H2 setup, with better drivability and reliability to boot. Below are some pictures that illustrate the two layouts.

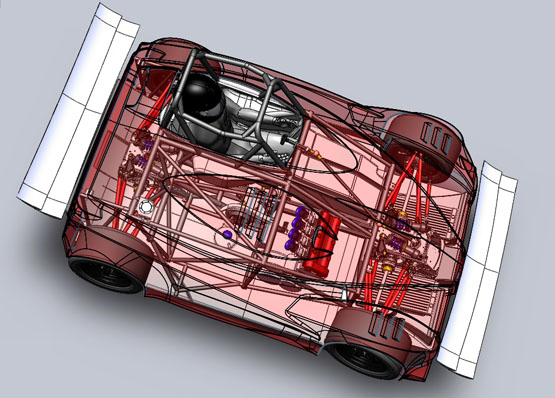

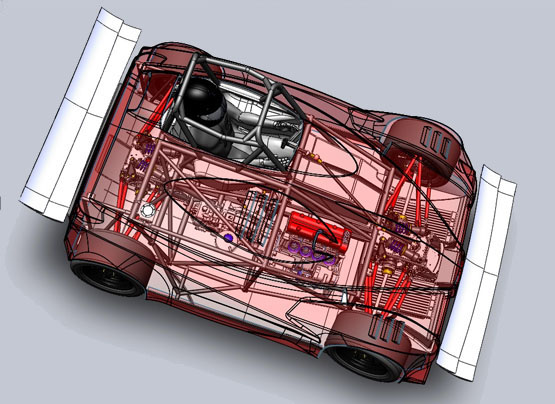

In terms of balance the H2 setup is slightly heavier but it's also closer to the centerline so overall I think both solutions would have a near-perfect weight distribution with driver onboard. I am currently looking at possible ways to be able to accommodate both approaches in the same frame. The central torque splitter retains its position which is good, but there are several concerns with mounts that would need to be worked out. Because of the tight packaging in the chassis it is not an easy task. Would be great to be able to pull off this level of flexibility, though. It would provide a ready fallback in case something goes not-according-to-plan. So while operationally funding is top priority, design-wise this is my current challenge - to figure out a way to use either engine in the same frame. Meaning that some systems would have to be designed twice, but that's what it takes. We already have a frame tube kit and all the suspension pieces onhand so while replacing some tubes like the rollbar with new ones is unavoidable, a further element of challenge to this design exercise is to keep as much of the existing stuff as practical. On the plus side both Tristan and I are getting more proficient with the CNC every day so when we do need to make custom parts it shouldn't be too big of an issue. We'll see how it goes. February 4, 2012 Quite a bit of progress. The big news is that we have decided to go with the Hartley H2/Hewland combo, AND use the longer D1 chassis and bodywork. It's still technically a D4 since it's not a V8 so we're calling it D4S for 'Special'. And it will be. The exact power numbers won't be known until we dyno it (and even then we may not necessarily reveal them) but I can say that the target is around 400 hp at the finish line. In a 900 lb car it should move right along. Yesterday we received the engine and the order for the gearbox was placed last week. The engine will need quite a few mods to make it fit our purpose but when all is done it will work really well.

Another item I've been looking at is the rollcage. I've been discussing it with David (he's the one who'll be going all-out with sheer drops and rocks on either side) and we've moved towards a setup similar to what he had on his open-wheel car in '05. Still subject to official approval and perhaps some change but below is generally what the car will look like. It should be fun!

Over the next two weeks there will be a lot of design work and activity, at the end of which we should be able to order the frame tubes. I'm also researching turbo options and we're planning to do quite a bit of simulation to figure out the best setup. It's a science in itself and there's a lot to it. The altitude makes it particularly challenging - by comparison if I were just picking out a turbo to run at sea level it would be a relative slam-dunk. But while or testing has to be done at sea level, where atmospheric pressure in 14.7psi, the race starts at 9,400 feet where pressure is about 10.5psi and finishes at over 14,000 feet with pressure dropping to a mere 8.5 psi or so. The goal is making the power delivery as consistent as possible and have the boost come in as early as we can. Yes, dual turbo setups will be evaluated to see if it's worth the extra complexity, cost and weight. When the testing starts at ORP we will be running this car back to back with a D1 and a standard D4 so there will be a lot of learning taking place.

|