|

06/30/11 Among all the things going on I have inadvertently ended up with a tinkering project. A few months back I purchased a 1973 Honda CB350Four. Well, actually I wouldn't have gone out to buy something like this. Originally it was given to me but then somehow I was asked to pay for it after I had done a bunch of work already. Nevertheless it was cheap and kind of cool and I thought it would be a nice beater to run around on. There was some concern about its age and condition but my brother Jared is well connected in the Portland bike scene, (The One Motorcycle Show, SeeSee Motorcycles, THP, Inc., and The 555 Ride) so I figured I have a good source for parts and knowledge.

When I got the bike it was running and came with a un-dented ready to paint gas tank to replace the beat up one on the bike now. A number of things needed fixing, like non-functioning electric starter and a lot of miscellaneous bits. The plan was to slowly work on it whenever I have the time and can figure out how to do the task by myself. To start, I thought I would give the Honda a once over as I have a rule about new-to-me, used vehicles: change the oil when you buy it, because you don’t know when it was done last. And so it began, the hell that is repairing vintage motorcycles with little knowledge of bike maintenance. I made a list of things that needed to be done, bought the parts, and rode the bike to my brother’s shop. I started with a new starter button and petcock (it was leaking a lot of gas). I did the repairs myself with a little guidance and my brother even gave me new handle bars to install. All went well and I rode the bike back to the shop in the rain. I was thinking this is not too bad, I have a bike! This was last Fall. Then in the following days (weeks, months) weather turned really bad and the bike sat for quite a while. Once I found the time again, I decided that since I’m changing the oil I might as well do the spark plugs and the chain. Again I bought the parts and got to work. I soon found out that I was given the wrong spark plugs, and my oil filter housing is missing some parts. Also the chain was so bad that Tristan needed to cut it off. Once the chain came off it was clear I needed a new rear sprocket. A phone call to Jared and I had a new rear sprocket for the price of a few dozen homemade cookies.

I put the bike back together with the old sparkplugs, started it up and went for a ride around the neighborhood, then it sat for a while more. One day the weather looked good so I got ready to ride and fired the Honda up only to find out the bike was leaking gas really bad. One of the carburetors was just dumping gas through the overflow tube straight onto the exhaust. I put it away and made plans to buy the carb re-build kits. A few weeks later I had the re-build kits and was ready to learn how to rebuild carbs as I go! I don’t have a manual for this machine and the kits didn’t come with instructions. RTFM wasn’t an option. So trial and error with a lot of bugging Tristan was the way I did my first carb rebuild.

I only got 2 kits because only 2 carbs were leaking (or so I thought). Tristan and I tested and retested the carbs before I put them back on, all was fine. The next day I wanted to ride so I got all geared up. Sitting in front of the shop the Honda was idling fine and sounded good. I got on the bike, put it in gear and it instantly died. On top of that it started to leak gas again. I was so mad I almost purposely kicked it over on its side in my cursing tantrum. After calming down I bought 2 more carb rebuild kits and did the whole thing all over again. By now the process only took me about a hour. Check and recheck, all carbs are no longer leaking, reassembly time. Everything is back together, I go to start it and I have no electrical power. I check all connections everything is fine. I know nothing about electric systems so I bugged Tristan yet again. He couldn’t find the problem either. So now the cursed thing sits there waiting for someone to help me diagnose the issue (dp has been alternately too busy and not willing enough to tackle it). I can’t help but think that this isn’t worth it any more. I’ve put more than half again as much money into parts as I originally paid for the whole bike and a whole hell of a lot time and blood. I’ve only ridden it about 5 miles. I know that it could be a great commuter for me and just be plain fun, but it’s hard going right now. As dp would say, maybe I just don't have enough Zen to do motorcycle maintenance? UPDATE: dp looked at it and fixed it in a couple minutes. It was a loose connector on the main relay. 38-year-old wiring, it's amazing any of it works really. 07/06/11 Alright time for a very belated post about the two day Porsche Train day at ORP. It has been quite a while since I last drove on a track, in fact I just looked in up and it was October 2010. Since then I did run a 5-minute session at Pat’s Acres kart track but it’s not the same. Lately I’ve felt like pit crew, a role I don’t mind. It can be fun at times. I’ve even brought my kindle to the track quite a bit lately knowing I’m not the driver that day. I guess I could have driven since October if I had asked or bumped someone else’s time. I just felt that the guys have earned the seat time so they should get priority. I wasn’t really planning to drive at this event either but dp basically made me do it. By now I know my patterns, I’m very reluctant to get into the car at first, when I finally do I’m extremely slow. After about 20-30 mins I pull off and say yeah I had fun, when in reality I was scared and just trying to keep the car on track. Then about 20 mins later I’m jumping up and down to get back into the car. This second session usually proves to be a little faster, and not scary at all, very fun actually. Once I’ve gotten past this I’m hooked and I want to be in the car all day (this is how I am with any car, not just the dp4). I’m not the type to leave early from a trackday, but I guess that’s because it takes me so long to get in the damn car and get going! With the combination of not being a morning person and not sleeping well the night before, I slept in until 10am for the first day. I ‘took my time’ getting ready, then it was lunch time. I finally got pushed into the car after lunch. I only did one 15-20 min session that day with a best of 2:14 which is quite slow for this car but wouldn't be too horrible for something like the MINI. dp and Tristan did most of the driving for the day. BJ also ran a short session and did a 1:43 on his 5th lap! Monday night I did some ‘homework’, I looked at my data and BJ’s data and talked with dp about the line. I find it funny how being told to go faster works. Well sometimes. I’ve known for a long time I just need to use the gas, floor it!! Tuesday was my day, I kept asking dp and Tristan if they wanted to drive, both said no thanks. This left me with the dp4 to myself! My long-term goal at ORP has been to break the two min mark. It’s not very ambitious of me, but considering I’ve been doing laptimes in the 2:16s it was a realistic goal to set. Throughout the day dp and I looked at data and videos, most of it boiled down to just go faster! And that’s exactly what I did. I started using the throttle and revving out the motor. I even started stepping the back end out a little in turn 8 or the “north bowl”. This car is amazing, it just wants to go faster and faster.

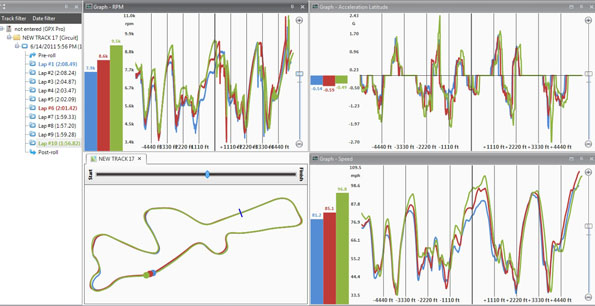

I should have had a helmet mic, it would have been hilarious. I spent most of the time cursing at myself when I messed up, saying things like don’t lift-don’t lift-don’t-lift, and shouting in happiness when I crossed the finish line with a new personal best time. At some point during the day I had a little group of people cheering me on at start/finish. The data for my second (and best) session of the day is below, click on the picture for a larger version that you can actually read. The three laps highlighted are a 2:08 at the beginning (blue), a 2:01 halfway through (red) and a best of 1:56 at the end (green). That last time beat dp's best of 1:57 from yesterday. HA! The speed graph says it all - I just went faster everywhere. A peak of 2.4g cornering was fun too. By the time Tuesday was over I felt like I was walking on air!

After this session we did a short lead/follow with dp in a customer car. Having accomplished my goal I didn't need to push further and I was worried about the car. The whole day we were monitoring the cush drive, waiting for it to fail to see how it would fail. We had spotted the problem earlier so I was being a test driver. At some point I was black flagged, apparently something had fallen off the car - it was a piece of chain guard that was coming apart. I was in a groove and this did not help my lap times but it was just as well. I was pretty much done so we offered the car for a demo and of course the drive failed on the first lap! At least Tristan can't say that I broke it! 10/25/11 A couple of notes on past events. I had saved the writeups and keep meaning to post them. Now I'm taking Pearl apart for updates and maintenance it is a good time to reflect on the recent experiences. I suppose late is better than never. Porsche Train 8/15-8/16. From my perspective there’s not much to report aside from the fastest I've gone off-track yet. I had a high speed and what felt like high G spin at the bottom of the hill entering T5 CCW. I spun at over 100mph. At the time it was no big deal and actually fun, I got right back on track and came in to check out the car. Pearl was dusty but still mechanically sound. The next morning however I couldn’t turn my head to the left at all. dp was extremely nice and massaged most of the knots out of my neck but I was still in a lot of pain. (yes, I was wearing a HANS device when I went off) I tried a few sessions and my head just wasn’t in it and the few g loads I felt were painful. dp and Tristan’s advice for me was to go faster and I wouldn’t be able to think about the pain. Needless to say this didn’t work! So I sat around for most of this event- practicing my pit crew skills. Pearl was none the worse for wear though and set fastest time yet of 1:39 in the morning with BJ driving. PIR Lotus Day 9/1. Big contrast to the previous event. This day far exceeded my most wild expectations about what the D4 and I are capable of!

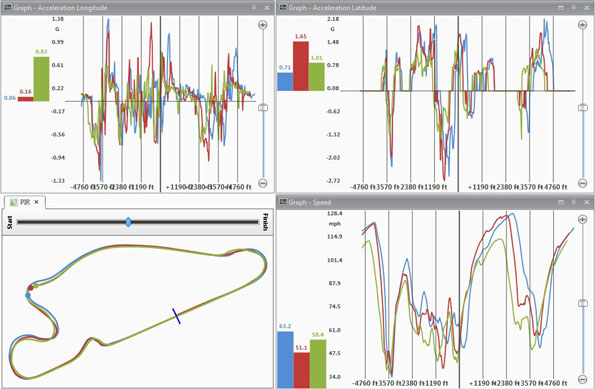

Even with skipping a few sessions and being stuck in intermediate for one, this was the best trackday for me in a very long time. Many of you out there reading this already know, but I ran a 1:24.8!!! -Insert perm-a-grin- : ) My goal for the day was to break 1:30. Below is the data (click for larger). Green is my 1:35 lap from a year ago, red is the day's best 1:24.8 and just for reference blue is Karl's1:21.8. It basically shows that unlike last year I'm starting to use the car with more confidence and going faster everywhere. There is more room for improvement but I'm happy :) Pearl is great, since we returned from ORP to the time we loaded it up for PIR nothing mechanical was done to her (is it really a her?). I did the prep work for Pearl this time, it was fun in a work sort of way but I really got to make this car my own. I cleaned the car top to bottom replaced some broken bits from one of dp’s spins and re-taped the nose. (ClearBra kits are needed and are in the works). I’m excited about the potential this car has and I look forward to attending PIR trackdays by myself. I’d love to be the guinea pig for running a D4 solo! Often our schedule at the shop prevents us from doing PIR events even though the track is only 15 min away. I hope soon that I will be able to do trackdays with the D4 at PIR with little notice, just roll her on the trailer and go. Pearl has had an eventful life so far as a prototype and demo car so before she goes back out again some maintenance and long-overdue updates should be done. Once the car is apart we'll re-powdercoat the frame, anodize lots of prototype parts, replace some with new redesigned components and service the major mechanical items. Since it's my car I will be doing as much of the work as I can and learning along the way. 10/26/11 I’ve been riding my motorcycle around quite a bit lately. Even in the cold and dark. So I decided to do a few small updates since a lot of basic stuff on the bike, like turn signals, didn't work. We had a tail light and some generic turn signals sitting around the shop. dp has acquired quite the collection of motorcycle bits and pieces over the years so it would be a matter of scavenging what I can and making it work. I’ve owned a few POSs in my time and I should know by now that there is no such thing as a quick project with these things. I thought I could change out the taillight in a few minutes, wow was I wrong! I took a look at the taillight on the bike and the taillight I wanted to install, and they looked similar enough that all I needed to do was fabricate a bracket to mount the new light and plug it in. I wanted to remove the very large stock classic CB tail light and license bracket. In a way I’ve decided that I’m going to fix this bike up as a kind of hybrid between a café racer and a restored classic. I quite like the completely original cb350Four look but at the same time I like the café style too. So basically I use what parts I can get my hands on and buy a few bits here and there. I fabricated the bracket and installed it in no time, I even moved the license plate and installed the turn signals. Then it came time to plug the taillight in, three wires coming from my bike and two wires from the light. I don’t know much about wiring and electronics, but I thought I could make something work. It turns out the new tail light was only a brake light, with a two wire bulb. My bike needs a light that can stay on (running light) and a brake light. The reason for the three wires was now clear.

So now I had a to make a three-wire bulb work in the new housing. Around this time I thought I should visit my brother at his shop and see what kind of parts I could bum off of him. I also needed the internals to the left hand controls (blinker controls). The left side wires were there but tucked behind the dash somewhere. This whole project went to a new level when I saw what was behind the headlight. At this point I had pretty much resigned to the fact that I would have to completely tear apart the wiring harness- if you can even call that rats nest of wires a wiring harness! Should have taken a picture of that but didn't in my distress. I was just about to fall into the rabbit hole that is untangling 38 year old wires. I didn’t make a list of what needed to be done, I didn’t want to think about it! So I just set up my work area and took the whole thing one system at a time.

I finally got the tail light to work but then the headlight wouldn’t work, and vice versa. I would get the right side turn signals to work but not the left, and vice versa. It was clear I needed a new turn signal flasher. Luckily I had just installed a modern fuse, when trying to get the blinkers to blink I blew that fuse many times. The web has proven to be my best resource for info. A quick search and I was off to Napa to pick up a generic flasher, one that is not thermal so it's not affected by low-power bulbs. Otherwise a replacement bike part would have been twice the price and wouldn't have worked anyway. In a poor attempt to fix my speedo I lubed the cable, also the throttle cables and tachometer (speedo still not working). I also replaced a few burnt out dash lights, repaired the headlight switch and purchased/installed a new headlight. All while learning as I went and going in circles fixing one thing just to find out I broke another! Eventually I got everything tidied up and working reliably. It's quite fun to flip the turn signal switch and actually have the signals work, knowing I made it happen. The bike is back together now and I’ve been commuting on it quite a bit. It’s a fun little toy. The more I ride it the more I want to ride it! : ) The pictures below are before and after.

I’m actually looking forward to tearing into the engine over the winter to stop the massive oil leaks. Everyone thinks my riding boots are new because they are so clean and shiny. They’re not- it’s from the oil spray that I constantly have to clean off (really safe right?!). Among other items this thing needs are new tires. I friend with the same bike told me he runs scooter tires (with the appropriate speed rating, of course) and that they are really cheap! We’ll see what I can find. My motorcycling budget is almost non-existent and I’ve already put a few hundred into it. I’m sure it’s nothing compared to owning a vintage Ducati or the like. 02/05/14 You know when you receive a text or email and you mentally respond to it but then forget to actually respond? Yeah, I do that all the time, especially with M's Corner updates. So basically what I'm saying is, sorry for not posting anything in such a long time. Well here it goes- I've been tasked with "figuring out" the D2 interior upholstery panels. This came about when I was talking with dp about how I'm swamped with and not enjoying the day to day work I do. Dealing with vendor issues, data entry, QuickBooks, AR/AP, making/updating BOMs ect. Vendor issues such as receiving bent, damaged wheels! Not fun Sometimes I just want to get my hands dirty! At home I'm pretty crafty (if I do say so myself) I make jewelry, home décor and clothes. I have a sewing machine so dp thought -hey!, you want to work on the car and you can make stuff with fabric, sooo upholster the D2!- (not his exact words but close enough :)) We have a few samples of a synthetic fabric called Santa Fe suede made by Enduratex. In fact we've had these samples for a while now because first we weren't quite ready for the interior trim then I found out it wasn't available. Just another difficult vendor issue. Since I was told no one had this fabric available we had to find an alternative that had the same look/feel and qualities like mildew and UV resistance, along with being durable enough to walk on and quick drying. Oh and FMVSS 302 compliant. I purchased a few yards of Alcantara outdoor as the closest alternative to the Santa Fe at a painful premium of $100 a yard! I took both suede samples home to experiment and try to make the look that dp is striving for. This did not go well. With this fabric corners are a mystery and forget about French seams or top stitching. Fortunately my task is to get it done, not necessarily to do it myself. At least I now know what it takes. So began another vendor search for an auto upholstery shop. After more time than I like to think about, I found one shop that had some idea of what I was talking about and didn't shy away immediately from the type of work we wanted. I set up an appointment and convinced dp he should go with me to better convey his vision. I also suggested we visit a local auto fabric supplier before the appointment to pick up some other things we needed and to get an idea of what fabrics and padding are available, so we can be informed customers at the upholstery shop. While waiting for the other supplies and looking through sample books (I love shopping for fabric!) I asked if we could get the Santa Fe suede. They called their supplier, they asked, they said yes! But, we had to order a whole roll, 30 yards- ouch. It turns out that the price of this suede by the roll is not too bad, roughly 1/8 of Alcantara. We ordered it, after all we have D2s to upholster :) Next was the upholstery shop. I was prepared, I've been through this a few times now. With ALL the samples (even samples of past work we don't like), a ton of D2 pictures and a full D2 seat loaded we set out. We met Craig and he seemed to understand what we were explaining immediately. He even took one of the samples and did a quick test for us, and gave us some materials to experiment with.. We left the seat with him because he wanted to experiment and make some panels for us. I like to work with these type of vendors - local, energetic,experienced and willing to go a little into unknown territory. We'll see what happens in the coming weeks. Stay tuned as dp would say :) |