|

06/26/10 The dp4 is back together again, started up and ran the engine for a while. Tomorrow we load it up into the trailer and head to ORP for our trackday.

Davide did a nice job of cleaning up the Pilod Pod. Production versions will look better still but this is good enough for the proto. Three days ago the car looked like this:

Now it's a little more complete :)

Unfortunately the dp1/e is still not done so it won't be going to the track. We'll have to test it at Pat's acres next week instead. Maybe just as well. Another annoucement - yesterday our second intern, Wyatt, officially started. We can use the help. 06/28/10 A second track test for the dp4. Arriving Sunday afternoon before the Monday event we still had some daylight for pictures:

After the customary evening barbecue and a rather unrestful night (for some reason I can never sleep well here) we were up early to get the day going. Since the car was a bare frame just five days ago without any testing at all until we went out on the track some caution was called for. I did a couple exploratory laps at the end of the first session and all appeared to be well except for a possible alignment issue. We checked and reset the alignment and in the second session I went out to progressively build speed. The result was a 1:56 best lap, with the car still having a lot in reserve. The video is now on YouTube. Editing the clip made me think how simple the GoPro camera is to use compared to what I've tried before. No big to-do figuring out the mounting, setting it up or turning it on - just snap it in and push the button. And the video quality speaks for itself. I like it. As always, Ben of xqsmephotography.com was there to take pictures during the event - here are a few of them.

After my full session I let M and Tristan drive the rest of the day. Both managed to spin the car, Tristan even high-centerd it on a tall curb. Turned out to be a good test for the prototype which handled it with no issues. Aside from tearing off a couple of the plastic rub strips on the underfloor there was no damage to speak of. Quite a bit was learned today and we'll have even more info after we go through all the datalogs from the dash. One of those things is the need for lower gearing - I use 1st for most of the track and briefly 2nd in three spots so we're basically driving a 2-speed car. 07/03/10 In preparation for its Laguna outing we're making a few changes to the dp4. The first is the 'Laguna muffler', hopefully it'll help us meet the 92db noise limit. Another is the mandatory front tow hook (good to have regardless).

A third and much needed change is the gearing - we're switching from 17:29 primary drive ratio to 14:31. This drops the 6th gear redline speed from 210 mph to a more realistic 160 mph and top speed in 1st from 85 down to 65.

Looking at ORP datalogs it means that instead of just using 1st-2nd we'll be using 1st-4th. Laguna is a very similar track actually, being 2.25 miles to ORP's 2.5 with elevation changes and speed range being very closely matched. So the gearing should work there as well. 07/07/10 The original plan was to be getting on the road right about now. However the guys at RMS are still feverishly working on adapting the new motor enclosure to the car (the assembly will actually have to wait until we're in California but we'll have two days to do it there). It saves about 50 lbs, allows us to use 6 more cells in the battery pack, eliminates an interference problem with the floor. And it looks a whole lot better. So it's a worthwhile endeavour but it's definitely adding to the stress. Now the plan is to start driving about 6am tomorrow and basically spend the whole day on the road. In the meantime, the dp4 is all ready to go - even the body tilt-up feature has been prototyped by the joint efforts of our interns.

We've put off loading it in the trailer due to the delays but now it's time to go do that, then get some sleep in preparation for the drive. 07/08/10 After this trip is over we are going to wish we'd had a film crew along. This is going to be an endless stream of challenges and setbacks, all to be overcome. Get up at 4 am, drive to the shop to pick up the Mothership, then to RMS to load the dp1/e. That car's story is on its own page. By 6 am we are loaded and ready to hit the road for the 750 mile drive south. We're going to do it in one shot stopping only when absolutely necessary.

Maneuvering around the RMS parkinglot we learn that there are some places the Mothership shouldn't venture into, even if they look wide open. Not a huge deal but I'm glad the trailer has built-in rollers at the back. Jeremy, Tristan, Davide and Kyle (from RMS) are coming along in a 'support' Ford Focus while M and I are piloting the Mothership. We're still not sure of the gas mileage for the rig so we stop a few times to top up. Seems to be getting about 9-10mpg which is not bad. Mountain passes are a challenge - 40 mph on the way up, then same speed on the way down because that's where the engine brake is the most effective. The engine brake is awesome though - I hardly touched the main bakes on a 7-mile stretch of 6% downgrade. Then, California. California roads suck. Interstate 680 in particular, it's so bumpy that I'm starting to get worried about the stuff in the back. Rightly so as it turns out. We finally arrive at Laguna campsite around 9 pm. Checking in the back of the trailer reveals that a couple tiedown straps have come loose from all the bouncing. The dp4 has slid around, banged up bodywork and punctured two tires. The dp1/e is damaged also (which is on top of the fact that it's a kit of parts rather than a car at this stage). We have arrived for a three-day event with two dead cars. I take a deep breath, figure out a plan of attack for tomorrow and try to go to sleep. In vain - the stress keeps me up all night and I face the morning with less than 1 hour of uneasy 'sleep'. 07/09/10 M and I were both originally scheduled to run the dp4 today. Obviously this is not going to happen. The dp4 is generally OK, we just need to put on the spare set of wheels (they are of course different in size and have never been tested, we don't even know if they'll fit the bodywork). But the electric is going to need fabrication and parts overnighted to us so all our time and attention is going to be taken by that. Fortunately SpeedVentures, the event organizer, were very accommodating and allowed us to move M's sessions to Saturday and mine to Sunday when I'd only scheduled the dp1/e. On to the tasks at hand then, one hour of sleep and all. The morning is cold, miserable and foggy, with water collecting everywhere. Normal here this time of year. We drive to the paddock and unload the dp4 with considerable effort (the flat tires don't help its already minimal ground clearance). We then set up a place for Kyle to work on the dp1/e and put new tires on the 4.

With that done, the attention turns to logistics. M also wants to get some rides on the track and gets some blistering fast laps in Darin's Atom - around 1:33. Darin is a very fast driver (he got his Atom down to 1:23 at PIR some time ago). He also knows Laguna well and races a Spec Miata here consistently being in the top 3. He is scheduled to drive the dp1/e for us in the race. There are quite a few Atoms in attendance, this being the unofficial West Coast Gathering, and it's good to see some familiar faces as well as meet customers who I'd only known through e-mails and forums before. Unfortunately with our stress I don't get to spend much time socializing. Much more about this day on the dp1/e page. 07/10/10. Another cold and foggy morning but better than yesterday and it warms up quickly. And I've actually gotten a few hours of sleep. The car looks reasonably ready although with no testing we don't know how well it's going to work. We still haven't had a chance to revalve the shocks after doubling the spring rate so I know it's going to be bouncy. I'm hoping the wider rear tires will stabilize it somewhat. At least they fit well and look good :)

I go out in the first session. The car is fun but it's a bit of a handful. Seems to be very twitchy on turn-in to the left (but not to the right). Not the best situation since it's a counter-clockwise track and all the tough turns are left-handers. Given the schedule we won't have much of a chance to diagnose it either so I'm just going to have to drive it as-is. The rear tires seem to have hurt more than helped and it's a constant workout keeping the car in check. Fortunately it communicates instantly and is very catchable so there are no scary moments as such, just a relentless stream of corrections needed to keep pointing the right way. Adding to the entertainment is a new feature - the throttle tends to stick open. It did that to me going into the Corkscrew which was remedied with a few frantic bumps of the pedal while still trying to brake. And again going into turn 1 which required a shutdown and a later restart. Even without all that the track is intimidating. I've only been here once, on the 900 in 2001 and I was very slow then with over 2-minute best lap. So basically I'm very much out of my element. As the day progresses I get the hang of it a bit but I'm still slow, with the best of about 1:43 in a fair bit of traffic. I get passed a number of times which is a new thing to me in this car but I don't want to push harder right now. Too much on my mind. To further complicate things I get pulled in for sound violation - 95.8 db vs the allowed 92. We put on a piece of pipe to point the exhaust away from the meter and go out again requesting a sound check. 94.2 db this time so it means we'll have to half-throttle it up the hill from now on. It works but doesn't help the laptimes, not that they matter much at this point. We attempt several fixes for the throttle problem and it seems to help. M goes out in the intermediate sessions and is even more intimidated by the track and the car's newfound edginess so she spends her first two sessions driving in her mirrors looking for people to point by. The throttle sticks open on her a couple of times but she handles it well. We have a long talk and she picks up the pace significantly later on, after finding someone to follow around the track and learn the line from. At the end of the day she is just starting to get in the groove and wants to really start driving but it's not to be - tomorrow only I am scheduled to run and we still have the electric to worry about. Still, she got to drive our car at Laguna. Hopefully not the last time. At the end of the day looking at the wear on the bigger rear tires shows that they definitely need more negative camber, something not quick to accomplish on the prototype (this has already been fixed for production). So we decide to put smaller tires back on the next day. 07/11/10 In the morning we swap rear tires on the car and I go out again. Definitely better and I'm more relaxed although only marginally faster. To add to our challenges the dash has some kind of internal error and is not logging data although it does give us running lap times - whenever I find the time to look while going into turn 1. The throttle stickiness is still there and as we are getting ready to swap in a brake cable from Jeremy's scooter, he finds the issue - there is a plastic tie wrap on the throttle body assembly that once supported a vacuum line and now dangles free. Until, that is, it swings just right to snag the throttle bellcrank if it's open just the right amount at the moment. Whew. After a couple sessions I ask Jonathan Frost, our newly signed up dp1/e pilot, to drive the dp4 and give me some feedback. Jonathan is an experienced racer and an instructor at Skip Barber. He takes the car out for a session and comes back smiling. A video of a lap is on YouTube - the lap is not his fastest (he did a 1:37) but it's the most fun to watch with all the passing. Climbing out Jonathan proclaimed it the most fun car he's driven at Laguna, and coming from him it means a lot because he's driven pretty much everything. He also noted that it's a workout keeping it in check. When asked what would enable him to go faster he replied 'Stability'. Later in the day we discover the major culprit of the twitchiness - the right front suspension was binding up due to a setup problem and causing the back to step out on turn-in. And of course the mismatched springs and shocks didn't help. So basically there is still development and tuning to be done which is not unexpected given that the car was a bare frame two weeks ago. It does look good on the track if I say so myself. For the pictures below, click on each one for a larger version. At the end of the day we focused on the dp1/e and when all is said and done, a very long effort was wrapped up by taking our time to put everything away and reflect on what has been achieved. The dp1/e blog contains the other half (2/3?) of the story so be sure to read that as well. I've now had two of my creations successfully run at Laguna, a lot of obstacles were overcome and a LOT was learned in the process all of which will be applied. Definitely a worthwhile trip.

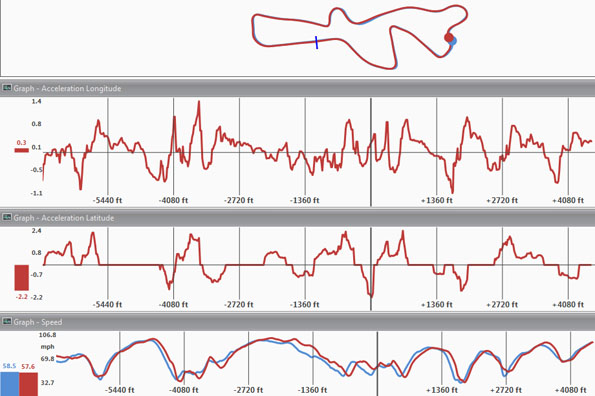

With the day done we packed up and moved the Mothership to a campground site up on the hill. The drive home will be split into two days with a stay at Lake Shasta to unwind a bit. 07/12/10-07/13/10 The return trip is largely uneventful, save for a flat trailer tire due to road debris and the realization that even our much more diligent tiedown scheme was still not a match for California roads. Fortunately we knew to check this periodically and the situation was remedied before it got out of hand. Now we really know what it takes and this knowledge has already affected the design of the trailer I'm working on as well as the mods we're planning to add to the prototype and the production cars. Knowledge hard-earned and all the more valuable for that. 07/29/10 Lots of work is taking place on the dp4 and other projects, it's just that after the Laguna trip it all seems a bit routine :) Monday we did our own private test day at ORP - it's much more productive than putting on trackdays because we have open track all day, no organizational headaches and can focus completely on our work. We did get some video and data but with no other cars out there it doesn't look all that exciting. Got the times down to 1:53 flat and the car still has lots more to give. I'm only starting to use brakes and carry cornering speed. With increased speed the rhythm of the track completely changes and I still need to calibrate myself to that. Using a pro driver would definitely help in getting much better lap times but there is certain value in me as the designer experiencing the car first-hand. I'm also more representative of the car's target market in terms of skill set so it's a good test this way too. The newly revalved shocks are working very well and the car is much more stable and is able to put power down early out of the corners. Chris at Shock Shop did the work and he really knows what he's doing. We've had numerous discussions on what the shocks actually do on a racecar and how they should be set up. Their primary job in our application is NOT to control body motion (with 800 lb/in wheel rates on a 900 lb car there isn't much of that). What shocks need to do is minimize tire force variation by removing energy from the unsprung mass. Chris firmly believes that adjustability of shocks is widely misunderstood and misused (and generally overrated). Adjusters simply open a bleed path for oil to bypass the shim stack, thereby partially or even substantiallydefeating it. Rather than messing with adjusters the shim stack itself needs to be configured properly for the car. That's what was done here and it works! The difference in grip is immediately noticeable to everyone who drove the car before and after. Improved gearing and newfound grip under power produced a peak of 1.0g acceleration. Peak cornering is 2.2g lateral in both directions (really fun in the halfpipe! :).

I'm still tentative with the brakes only using a max of 1.0g. We need more work on brake bias and to experiment with different pad compounds. Righ now I'm running Wilwood's BP-10 which is more of a street compound but I figured on a car this light it should be OK. Turns out if you get going fast enough even a light car works its brakes pretty hard. The speed graph above shows just how much I'm still leaving on the table by not properly using the brakes - the speed peaks are rounded from lifting early and a slow transition. They should look like a sawtooth pattern with acceleration building up to the braking point and the transition should be deliberate and precise. The blue speed trace is my earlier 1:56 lap and it's clear that a good deal of the 3-second improvement to the red lap is just carrying speed longer and braking later. It's very educational to look at the data - the GPS dash is a great learning tool and it is standard on the dp4. The 98F heat helped the tires but didn't help the drivers. It's great to have the air-conditioned trailer sitting right there. Hopefully later in the year we'll have some cooler weather before it gets nasty. We learned a lot from the testing done so far, which will result in some tweaks to the car's component design. This is why I'm offering a 1-year parts replacement warranty to the first five buyers. The design is by necessity a work in progress and if during the first year I discover things that need changing I will change them at no cost to the customers. I've seen some companies stubbornly bury their head in the sand and refuse to fix obvious and well-known flaws for years. We are definitely not going to be one of those. 08/10/10 Work continues on all the projects. On the dp4 front, we are making progress on the R1-powered customer car. The engine came out of a very fast Stohr DSR so it will be a very good comparison of chassis since engine and driver are the same. No excuses :)

08/21/10 Both the upside and the downside of our current situation is that along with our own cars we need to attend to a number of consulting projects. The good part is that we get to work on a lot of cool stuff and meet some great people. Also there's the satisfaction of being able to use our experience to a readily identifiable benefit. The negative is that some of our own projects are not progressing as fast as we'd like. But they are progressing.

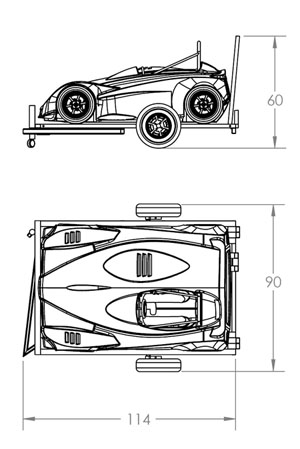

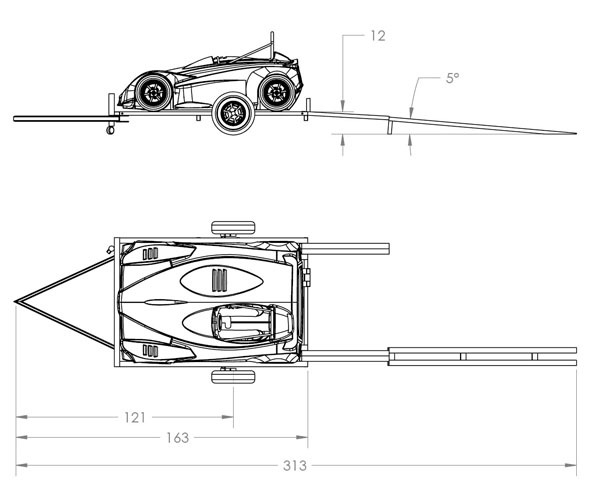

The current dp4 builds use uprights originally created for the dp1. While not as versatile as the newer modular GT/LT designs they are well suited for this car. I've got a few more sets on the shelf after which we'll transition to LTs, just for manufacturing efficiency. Our interns are just about done with their terms and so we all went karting at Pat's Acres, just renting the putt-putt hardware. M and I participated in the first session but weren't really into doing any more. On the way home we were discussing the fact that this type of stuff has lost much of its fun for us. On one hand, having driven the dp4 on the same track it's hard to get excited about 8 horsepower karts. On the other hand is the fact that I now approach each drive as a test session. It's a lot like work. So I was experimenting with body position (you lean to the OUTSIDE of a turn in karts, to get more traction on the outside rear and unload the inside). Sure enough, it worked well and while inside lean produced crazy slides and lots of opportunity to practice counter-steering the kart just railed through the turns when I shifted my weight to the outside. Nice to have instant real-world confirmation of engineering theory but ultimately it doesn't really help me a whole lot in what I'm doing. So I'm hoping that once we have a few dp4s out there we can actually just relax and drive instead of it being a crazy-stressful job, and we can simply enjoy putt-putt karting without projecting other stuff on it. Not this year :) Speaking of testing, at the end of a long day in 100F heat braking hard over a crest can suddenly seem like a good idea. In any other situation totally savable, but when the nut behind the wheel malfunctions this is what you get. On the plus side that was 2.5g through the halfpipe leading up to it. No damage done, which is a good test in itself. And no I'm not putting this one on youtube - it's just for those who follow the blog. In other news, some exciting things are being discussed but it's too early to go into details. Some of it could fundamentally change how we operate. We are even being approached with sponsorship inquiries which is all new and good. More on all that if/when it's more real. Even the exhaust header is the same, it fits as if it were designed specifically for the frame. We'll have to modify the end of it to point the other way but overall it saves a lot of work. A lot of other pieces for the car are already done so over the next couple weeks we should be moving forward pretty quickly. 08/30/10 For a while now I've been talking about a custom trailer for the dp4. It is really an essential piece of the puzzle - it's what will truly enable single-person operation of the car with minimal inconvenience. Normally if you tried to track something like a DSR you'd need a full trailer, a tow truck, a place to park them and at least one support crew. That's quite a commitment to make for just a few trackdays a year. The goal of the dp4 is to eliminate all that overhead. The pilot pod allows the driver to do his own belts - no crew needed. Bodywork lifts up for access. The car is small and easy to move around with just one person. But getting it to and from the track is still a challenge. Afterall not many people would jump into something like the Mothership :) The trailer is designed to answer that. The goals are ambitious: It has to be a Class I design, combined car and trailer weight needs to be about 1,500 lbs so it can be towed behind any car - even a Miata. Surge brakes are needed because a Miata is not likely to have a brake controller installed. It has to be easy to load and unload by a single person. And it has to be easy to store in a regular garage taking up a minimum of room. Protection from elements and some security are also desirable. So how does one go about doing something like this? Well, the trailer has spent a lot of time in my in-head 3D simulator and now I finally have it firmed up enough to do some initial CAD. I've gone though literally two dozen iterations before getting to this stage...

The extenal ramps store under the floor and the entire trailer weighs around 650 lbs according to Solidworks (might increase a bit still but not much). There are lots of details that are not shown but already figured out, like the tiedown scheme that draws on our experience with the Mothership. Or the aluminum frame and skins to make it an enclosed design. Of course many additional details still need to be ironed out but overall it's looking pretty promising and a number of key components are already picked out. Construction of the first one should start in a month or so. The trailer will be an option for dp4 customers as well as a standalone product and preliminary pricing is targeted at $2,750 for open version and $3,500 for enclosed. Subject to change of course but that's the ballpark. In other news, we're getting ready for some testing Friday and that will include aerodynamics. The electric should be ready for more tests by then as well. More when the results are in.

|