|

10/05/09 A few final suspension pieces and tweaks are in place...

Wheels are bolted on....

And there it is, sitting on its own for the first time.

It's a neat device to be in.

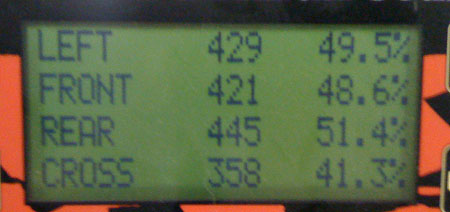

Of course the newborn is weighed (ignore the cross-weight being way off, there was no attempt made to set it so far, that will come later). A bit more than targeted but I'm not terribly surprised for this first prototype. We're still missing about 80-90 lbs from the car so it'll likely come in at 750 lbs initially. Testing, tuning and weight reduction programs will follow once it's drivable. Also this is the Hayabusa version, the 650 lb target weight is with a liter-bike motor which would be about 35 lbs lighter. Still I have a bit of weight to shed.

The second picture is with me in the car and the thing of interest there is the first line - weight balance is pretty decent. Also a slight rear bias, as planned. So here it is, looking pretty much like a complete car....

Well, minus the bodywork of course but that will follow soon. Next is trimming the wiring harness, filling the fluids and first start. After that fitting the chains and then it'll be ready to roll. No doubt much tweaking will be needed. 10/07/09 A car is a very complex 3D puzzle. A dynamic one at that. Many parts, all have to fit and clear each other through the full range of motion. CAD makes it easier but it's still a challenge, especially when in a rush. So now we're going through and making sure CAD matches reality which matches BOM, etc. Building one of something is quite different from gearing up to build dozens of something. Now is a good time to go through everything and make sure it all adds up to a complete car. A few pieces are not in place yet, obviously, but putting the test body on the rolling chassis does give a feel for what the finished product will be like.

To get a sense of scale here are some pictures with me in and around the car (keep in mind that's nearly 200 horsepower to the right of the driver's seat):

Or to put it in another context, this is how it compares to a motorcycle:

We've had a few vendors stop by and take a look at what it is they've been rushing to get done. One said "this is the car I've been dreaming about for 20 years, in the flesh!". Naturally everyone is waiting to see it run. Me too. Well, OK, we're doing a fair bit more than just waiting actually :) 10/10/09 In order to get the drivetrain installed and adjusted a lot of things had to be taken apart again. Tristan is getting pretty good at this. He is already the world's foremost expert on V8 Atoms, the dp4 is getting to be another item on his resume.

The chain guards, firewalls, etc are still in my head but they're making their way into CAD and into metal, one by one. Much has been done, much remains. Response to the dp4 continues to be overwhelmingly positive. Looks like people are looking forward to the finished product as much as I am. Cool. 10/16/09 In the process of fitting the chains we had to do quite a few minor tweaks and I made sure that they're updated in CAD as well. But the chains are now in, all fluids are filled, brakes bled, clutch and throttle stops set up, wiring harness modified (well, almost).

The last picture also shows the shifter linkage - nice and direct. Works really well. While all this is happening M has been very busy updating all the assemblies and BOMs in Quickbooks. We have an add-on multi-level BOM program that runs within Quickbooks and allows the entire car to be accurately entered in software. When we need to build one (or more) we just do a build in the computer and it gives a full list of parts that are in inventory, what the shortages are, how many of what needs to be ordered and even where from. Right down to the last bolt and washer. Pretty cool (ok, essential) when all is done but a lot of work to set up. Our recurring conversation is: "it's SOOO much work to enter all this stuff in" - "yep, I know, I designed it (and Tristan built it)". We do all work quite well as a team. This definitely beats the one-man-show that dp1 prototype was but it's also much better than having a dozen people with their own agendas and no common oversight - I've had to witness and deal with that a while back and didn't like it one bit. So basically we've got a good thing going here, just have to keep moving forward. The wiring still needs to be tweaked some - I need to come up with a better ignition switch, bypass the tipover sensor and the clutch interlock and generally tidy things up. The dp1 proto used the 'busa wiring harness as-is but I decided to trim it for this car since things had to be repositioned a bit anyway. I'm going to use the stock dash for startup but there's no room for it so it won't be used for actual first drive. The said first drive may well come tomorrow. I'm shooting for the 1-2pm window, but the forecast is solid rain so we'll see. It's imminent though, pretty much everything is ready. One might think I'd be emotional in some way anticipating it - but I'm not. Guess I've done this a few times now. Westie, dp1 proto, Atom, 3 electric car protos (no I still can't talk about them here but they were fun in their own way) and that's not even counting the dp1/e (I wasn't even there for that one and it was a born-again type thing but I think it still counts). Bottom line is, if the first drive goes well then great, if not then whatever glitches I find will get fixed. Progress will be made either way. Oh and before I get all kinds of emails, yes there will be substantial chain guards, fire wall, etc. Not for first putt-putt around the block but definitely by the time we get around to real testing.

|