|

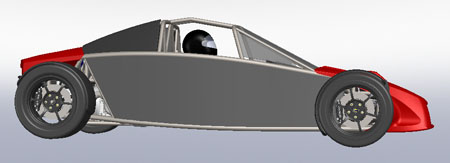

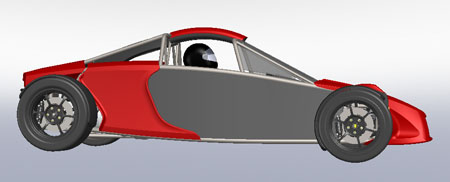

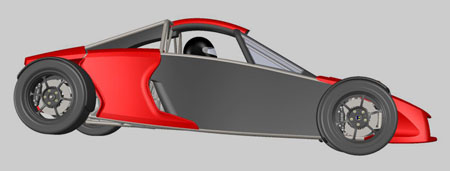

10/4/11 There was a lot of reaction to the styling updates. Most was very positive but some strongly preferred the earlier, cleaner look. So I thought it would be good to illustrate just how easy it is to customize the D2. Because the structure can stand on its own, you can either leave it to speak for itself or change the look with any combination of panels. Below are some pictures in the 'new' and 'simple' configurations. Endless others are possible. Obviously the nose and tail pieces are changeable too if one wants to go that far. The plan is to eventually have a number of panel kits, including full length side panels, full fenders and enclosed cockpit. They will all be bolt-on so an owner can change them after buying the car and can in fact have more than one set for different occasions. Some will take minutes to swap though others may be more involved. Optional wings, diffuser and floorpan will also be available. 10/5/11 More progress, this time on real parts. Picked up a windshield - it will be cut into 3 pieces for the main glass and two sides. I have a few leads on who and how can cut it but I'm sure it will be a learning process. Have done some research on the web and talked to a few people. So far it looks like many people think they can do it but breakage is a common thing. The leading process under consideration is waterjet but I suspect there are tricks to how to do it right.

Also the steering racks for the first two cars have arrived. These are custom made for us. The axles in the picture below are for the Stiletto but the D2 ones will be very similar except for inboard stubs. They're rated for over 700 hp.

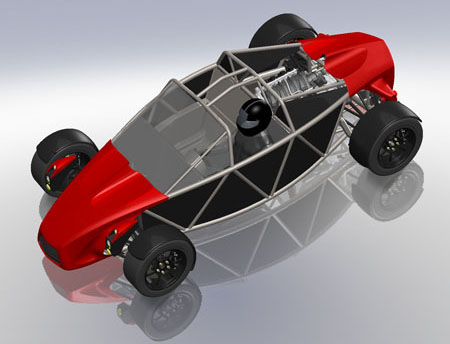

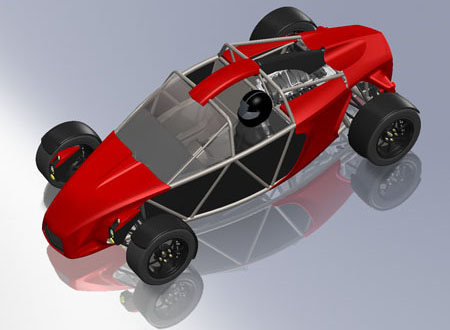

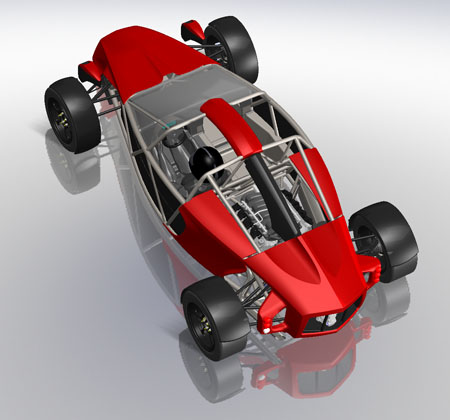

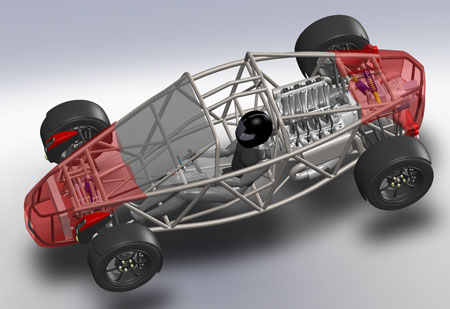

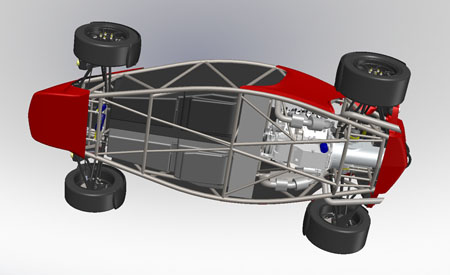

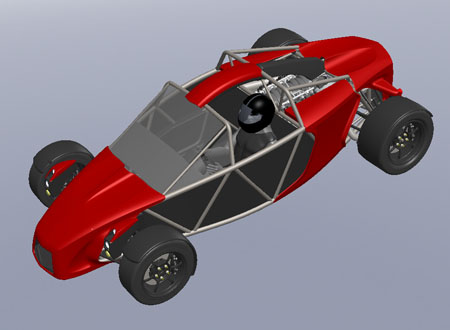

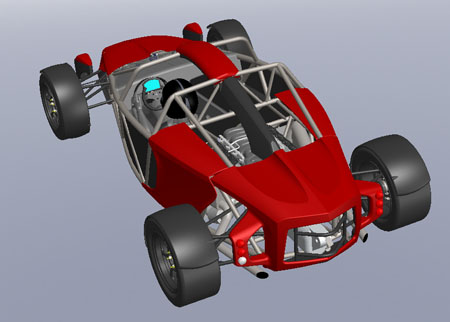

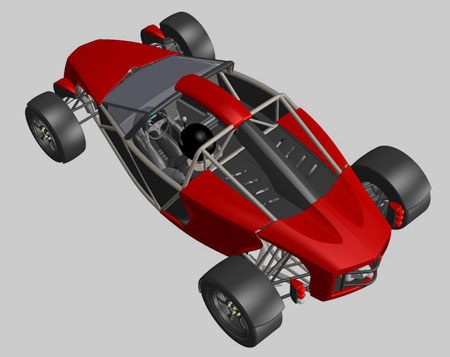

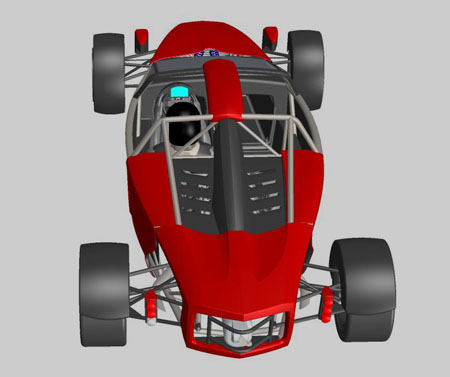

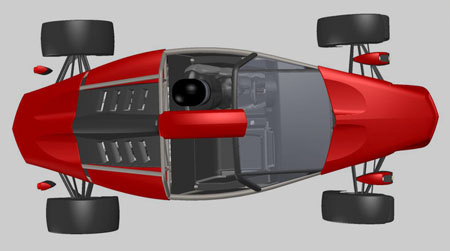

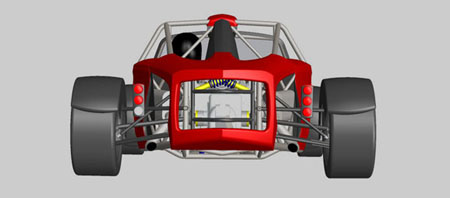

Now that the styling is reasonably nailed down I was able to finish the design of the bolt-on crash subframes for the front and back - you can see them in the picture below (click for larger). That was the last piece of the frame puzzle and now we can get on with making those. 10/22/11 September / October seems to be the time for first drives for me. Original dp1 Sept 18, 2006. Bikini Sept 17, 2007. First D4 Oct 17, 2009. D1 Oct 14, 2011. Only the Westie broke with that tradition with an April 27, 2002 initial run. With the D2 I'm aiming for a winter 'birth'. To that end much additional progress has been made on the design. I'm learning from previous experiences here - the D1 does not share a single part with the dp1 prototype (this is not exaggeration, just fact) and the production D4 while similar to its prototype in reality shares only a handful of components with it. Of the 64 tubes in the frame only 3 are the same between D4 proto and production cars. My goal is to avoid this with the D2 to the extent possible, seeing how the first car is going to a customer. So I've been approaching it in 'bursts', with a period of intense design activity followed by a cooling-off break and then coming back to it with fresh eyes. This approach has been paying off and there have been lots of revisions, many driven by lead customer input. Since the last post the wheelbase has grown 2", legroom increased 1", engine moved 3/4" down and 1" forward, there's revised tubing under the engine to better protect the oil pan, tail is 1" shorter, crush structure tubing is revised, windshield is modified, bracing around the cowl is new, and so on. It may not look radically different but the changes are what would normally take place between prototype and first production unit. NOW I think we're finally ready to pull the trigger on the frame tubing. Will have one more final review Monday.

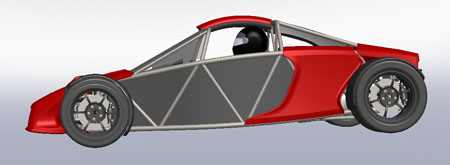

Some of the feedback I've been getting is that not everyone is a fan of the exposed frame tubes. In thinking about how the side panels would be built I've come up with a solution that could be used for either a 'full-exo' or a 'smooth' look. The panels would be made in one piece but can be segmented and installed recessed if one wanted an exposed frame. A couple of the 'smooth' versions are illustrated below. This is going to be fun :)

11/08/11 I realized that with all the updates and communications with vendors I haven't posted anything on the D2 in a bit. Below are the latest screen shots - the most notable chages are addition of engine cover and windshield surround and refinements to nose, tail and sides. First tube kit should be here in about 4 weeks, the real fun starts then :)

I keep thinking I need to do something sexier with the lights but the exact solution hasn't popped into my head yet. I sketch stuff occasionally but so far nothing that would be an improvement. Not a big concern at this time though, lights are easy to change even after the car is built. I do have the actual projector units here - nice Hella 50mm halogens. 12/05/11 A few developments. The first set of bent tubes is here, arrived a couple days ago actually. They are made by a different process than the rest of the frame and so come from a different vendor.

The rest of the tubes are not far behind. This is where the car starts to come together in real life. Another bit of news is the arrival of our new (to us) CNC machine. It will greatly improve our ability to do prototyping, low-volume production parts and just-in-time manufacturing (many thanks to Karl for making it possible). In the past we've had to either order way more parts than we need or pay a significant per-piece premium. Now we'll be able to machine what we need, when we need it. Or at least that will be the capability once we have everything set up and running smoothly. There's always a learning curve, even though Tristan has run such machines before. We do have some very experienced friends we can call on for help if need be.

The pictures are reminiscent of when the chassis table was delivered three years ago. The mill is an overdue addition to the shop really, we could have used it a while back. It should pay for itself in short order. But in the immediate future it's more work for both Tristan and I, just in case we weren't busy enough already :) As of the end of the day the machine is powered up and just about ready to run pending some minor maintenance and tool acquisition. Yet another step forward. 12/8/11 The first D2 frame tube kit is now here. We'll be starting on welding it shortly.

I haven't done anything with the styling in a while, just letting it simmer in the background in my head. One quick and easy thing I did do was black out the 'scallops' on the nose and tail (per earlier customer suggestion). I think it looks much better. Whether or not this is going to be the eventual solution, at the very least it indicates a direction and the need to further resolve some of the elements. Click picture for larger version.

|