|

8/8/17 Quite a while since last update on this blog. Those who followed it know about our Pikes Peak adventures with Rodney's D1. It went well with Rodney taking 3rd in Unlimited again, sharing the podium with Romain Dumas and Paul Gerrard (who we later learned has been The Stig on US edition of Top Gear for the first few years).

Rodney's car is now on its way to Taiwan where we hope he'll have a lot of fun with it.

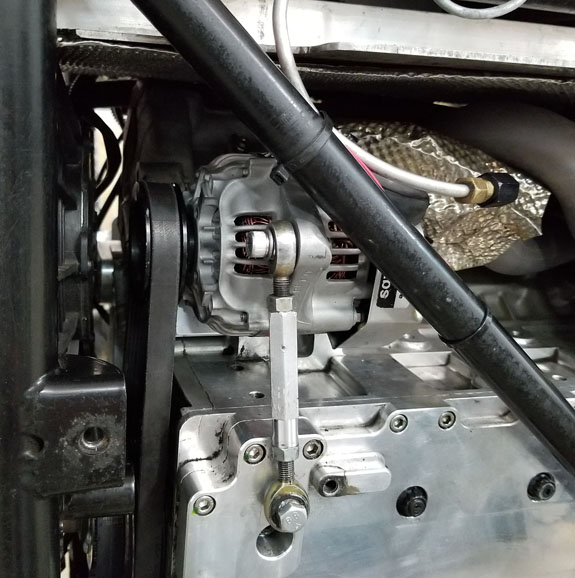

In the meantime Neil has been driving the wheels off his V8 D1. There haven't been any major issues, but a few service things along the way did need to be done. For something of this performance level it's laughably little (think what LMP teams have to do for every race in comparison). One thing has been the alternator and I finally figured out that the bracket design is inadequate and is the root of most issues. So I redesigned it and made a new one.

Due to 10K RPM redline and very rapid engine speed changes with paddle shifter and virtually no flywheel, the alternator drive gets a lot of shock loads. We kept breaking high-strength bolts and even wearing out the mounting hole on the alternator itself. The new double-shear setup should take care of it. Another thing we've run into is that the car suddenly overheated. Bear in mind, it's been fine for over 100 hours of very hard driving so far. But this seemed very similar to Rodney's surprise overheat, also after being fine. So we replaced the thermostats (quite old now) and rerouted the fill line to prime the pump at all times. Problem fixed. A subsequent run at PIR in 105F ambient proved the system workd well, with water temps staying below 205F. And Neil managed a new personal best getting into the 1:16 zone with the chicane. That's moving pretty well.

On the subject of service, people are always amused to see pictures of the cars on their side, but this is really the most efficient way to work on it. We do avoid leaving it this way for more than a couple hours, just to keep oil from seeping past the rings. Other than that, it works great.

Many more adventures ahead, and of course much is happening on all the other cars too. Site Sponsors and Links:

|