|

08/18/11 This is where the real fun starts :) Picked up the bodywork from Stohr. It's all carbon and weighs just 30 lbs (the original dp1 proto body was 41 lbs).

It will eventually get painted but for the first drive we'll leave it in bare carbon. I'm quite pleased with how it turned out. We'll be fitting it early next week, after the engine is back in the chassis. In the meantime the floor molds are done and the first floor (also all carbon) is due in about 6 days.

The sump and pump have arrived from Hartley and will get installed in the next day or so. Very cool parts and it's good to see that John continues to evolve and develop his engine just as we develop our cars.

Chassis-wise, the chain guides are nearly done. The front one also acts as a firewall, heat shield and scatter shield between the engine and the pilot pod, kind of a belt-and-suspenders approach. It's made of 1/8" 6061 aluminum plate reinforced with 1/4" thick bars and gussets.

More soon. 08/26/11 We're going like crazy on this car and still doing some stuff on pretty much all the others at the same time. Fun, in a twisted kind of way :) The floor is done, it will be trimmed and mounted shortly. Haven't weighed it yet but seems about 15 lbs. It is two pieces with the nose piece being separate (not shown, it looks just like a flat panel even though it's not actually flat).

We've been rearranging and cleaning up the shop lately so the new bodywork temporarily hangs on the wall, exactly where the original dp1 proto bodywork used to hang.

Pilot Pod plugs are now sprayed with mold release (needs another coat in the pic) and Tristan will lay up parts later tonight.

Mechanicals are moving forward too although it's hard to immediately see the progress - it's mostly brackets and fittings.

I've got a whole weekend of wiring and plumbing as well as designing brackets and mounts for all the miscellanous bits like battery, fire system and paddle shifter components ahead of me. Joy. 09/07/11 Not much in the way of updates lately but LOTS of work. I'll skip to the interesting part - the car is now on its wheels, the floor is fitted (and the body at least test fitted).

It's odd to think of a car with 80" wheelbase as 'long' but that's exactly what I think when I look at the D1. Got really used to the D4s I guess :) There's lots of less glamorous stuff too, like a wiring harness that's mostly done, nearly $2K in plumbing parts and so on. The Pilot Pod is out of the molds and turned out pretty nice (still needs to be trimmed and fitted). Somehow I don't seem to have a picture of it right now. The push is on to get the car running in the next couple of days. Wish us luck. 09/10/11 No, not done yet. Close, though. It really shouldn't have been a surprise to me but somehow my memory of what it took to get the Atom running has been altered by the fact that we can do a complete D4 engine transplant including changing exhaust, engine mounts, shifter, wiring harnesses and making plumbing tweaks in under three days. This is a far more complex beastie and wiring harness alone took a week. Wiring is a messy business, although the results are pretty tidy. Had to wire all the sensors (there's a ton of them), the ECU, the GCU, the dash and the logger (still a couple wires to run but mostly done now).

M made a nice carbon dash panel...

Seems it's now her turn to do composites duty. None of us like it - it's an exhausting, sweaty, itchy business and the Tyvek suit only helps so much (and makes it way hotter). Tristan did a lot in the past, as did our interns and Roy, our honorary 'guest worker' :). Then I made the pilot pod plugs and the pilot pod sides themselves. Now it's M's turn to trim them and fit them in the frame.

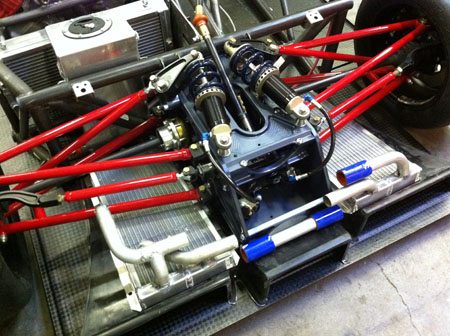

The concensus is that while we can all do it, composites is a job that's best left to people who are set up and trained for it. So in the future the plan is to do exactly that (but I still get to prep the new D4 plug because I'm testing a particular way of doing it, hopefully the last bit of composites work inhouse). In the meantime Tristan has been hard at work on the plumbing. With my customary tight clearances it's not an easy job. Yes, the radiators are in parallel - we'll see how that works, water temp will be logged. Yes, the tubes run through the suspension. There's only 3/4" total travel so we can do that. Yes, waterpump is electric. No, this complicated welded arrangement is probably not a long-term production solution but it'll work for now and we'll learn a lot from it.

The oil and water plumbing are now essentially done, fuel has been started, electrical is 95%, pilot pod fitment about halfway. Tomorrow is a busy day. I haven't had a day off in a month. 09/14/11 It's been too crazy for updates lately. Here are some highlights though... Over the weekend we fitted the Pilot Pod and made sure Karl fits in it. Perfectly, in fact. Yes, the entire thing will be carbon (and some Kevlar) - the sides are just temporary pieces to verify fit, molds will be made from them shortly and then production parts will be made in the molds.

Yes, I have to remind myself that's a 430 hp engine next to him! But from running the D4 we already know the chassis will be up to the task of handling the power and putting it to the ground. On monday we went driving at ORP (private test day), tuesday was our last chance to fire up the car while Karl is still here.

End of the day, everything wired up, fluids filled, the engine turns over... nothing :( Quick diagnostic test shows the ECU is not seeing the crank sensor. But it's late, we're all tired so we call it an evening and the next day Karl flies out. Today after a bit of much needed rest I find the source of the problem - when I assembled the wiring harness I didn't push the ECU connector pin far enough into the housing! A simple push with the end of a paper clip, Tristan turns on his phone camera, I flip the switch and it fires right up (click on picture below for video). Now on to the rest of development. The Geartronics paddle shift system is the next in line. 09/22/11 With the Sunriver show (and the need to take a break after the crazy push of the last couple months) the progress has temporarily slowed a bit but there is still some. The exhaust is now finished.

The sections aft of the horizontal frame tube are removable and can be easily replaced with mufflers similar to the D4, for tracks with low sound limits. The body has been further trimmed and the mounting latches are now on (although they aren't in the pictures below).

On the less visible side I'm going through the wiring and diagnosing a couple sensor issues to make sure we're ready for the paddle shifter calibration. Most likely that will happen next week. 10/12/11 Always finding more things that need taking care of. This of course is normal for the first build of a car. One example - the existing intakes rubbed on the bodywork so we turned them around, requiring the fabrication of intake runners.

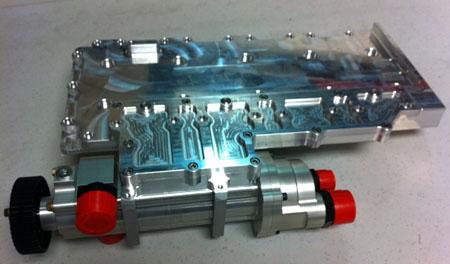

This is a temporary solution. I will design and make a whole new airbox later. Will do for now though. A synchronization issue between the two engine banks had us scratching our heads for a couple days - once we figured it out the fix took only a few minutes, a simple adjustment. But that's how it goes sometimes. Anyway, today we finally tested the Geartronics paddle shift system. It's a very sophisticated setup. Just from looking at all the variables it takes into account it's obvious that a lot of development and testing went into it. The shifts are very seamless even at partial power (which is harder to do than when going all-out, as anyone who has used a sequential gearbox knows). I've uploaded a video, click on the picture below to watch it. The clutch is only used to get moving. All shifts, up and down, are taken care of by the Geartronics uint and yes it blips the throttle on downshifts. Good thing, too, as the car will go through gears very quickly. It's interesting that the ignition on the V8 interferes with the GoPro camera - sound is just electrical whine when I tried using it so this video was done with my iPhone. Will have to sort this out later. Tomorrow we'll go through and tidy everything up, do some additional tweaks and tuning and generally get the car ready to drive. The goal is to run at a kart track Friday morning if the weather doesn't get nasty again.

|