|

11/09/09 (updated 11/10) More progress on the exhaust, although Tristan is not particularly enjoying it. I guess we'll have to come up with better ways to do this. Of course part of the solution is to have the headers CNC bent but because of the close multiple bends they can't be done as one piece. Still, it will help.

UPDATE: after the above post I received an e-mail about a very neat piece of equipment - a NISSIN 3D bender. Watching the video is really cool (one site describes it as 'pooping steel' and, well, it kind of does look like that). The advantages are obvious - multiple radius bends, no distance needed between bends, low deformation, no custom dies, etc. This thing should be able to do our headers with no issues and no seams. Of course we aren't likely to run out and buy one, but I did find a bending service company that has one of these and I'll be getting a quote from them in a couple of days. We'll see if this technology is cost-effective for low volume parts. 11/19/09 The exhaust headers are now fully welded, all that's left is attaching the mufflers and tailpipes and then we can ship the whole thing to Hartley for dyno testing.

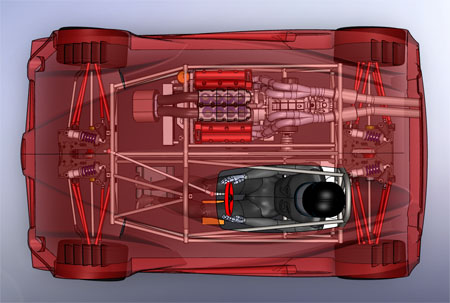

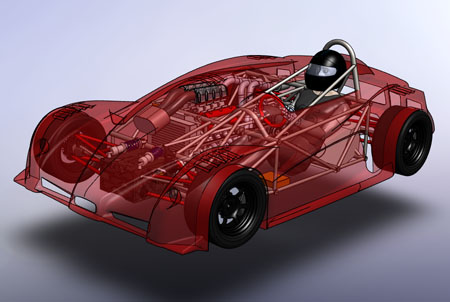

It will be interesting to see whether this is enough exhaust to actually make 500hp. Ideally the primaries should transition to 1.75" a couple inches from the head but there's no room so these are 1.625" all the way. The primaries on the Atom are 1.5" - enough for 400hp but not much beyond that. Turns out the vendor I had identified with the 3D bender only has a small version of it, not enough for this size tubing. So the search goes on. Would really be nice to find someone who can do this type of work. Doing these from pre-bent pieces is a bit more effort than we want to have in production. 12/06/09 It almost seems like full circle but having learned from all the lessons of the past year I'm exploring a tube frame for the dp1. Don't worry, there will still be plenty of carbon on it - the aerodynamic and styling bits. But for accessibility, service, manufacturing and even safety, the mixed tube/composite approach I've settled on for the dp4 just makes too much sense to ignore. So, taking advantage of the parametric nature of Solidworks, I morphed the latest dp4 frame and suspension boxes into parts suitable for the dp1.

Naturally there is still lots of tweaking to be done and all is subject to change but this exploratory design effort looks very promising indeed. In the meantime the completed exhaust has been shipped to Hartley for dyno testing of the dp1 engine, the first Hartley with a shot at the 500hp benchmark. I bet Simon at Ariel is going to be watching the results anxiously - he had promised the world 500hp (not quite sure why, the 400 horses I've installed in my Atom are perfectly adequate and sufficiently entertaining for a RWD setup). Me, I'm just curious to see how close we come to the number. With a sub-1,000 lb AWD car the distinction between say 475 and 500+ hp is pretty academic. Also, I know from the start that my exhaust is marginal for that power level and may end up being a restriction for the engine. I can tell you I wouldn't want the job of fitting a proper 500 horse V8 exhaust in the cramped UK Atom chassis.... Some may recall that car was originally designed for around 120hp. It'll be fun to see what happens there, if anything. Things are definitely happening here. 03/30/10 The focus has been primarily on getting dp4 out into the world (and a few other projects), although work continues on updating the dp1 design with everything I'm learning from the dp4 development. It'll be a much better car for it. The 3.0L engine so far has made 460 hp - short of the wished-for 500 but good enough for what we're doing. After a few more tweaks and updates it'll be shipped to us and by then we should be ready for it. In the meantime today the original dp1 plug and mold got picked up - they are going to Preble High School in Wisconsin, to help students learn how to build racecars. Not having a forklift we had to improvise a solution to load some 2,000 lbs into a semi. Fortunately our four-post lift has casters on it - everyone but me was skeptical but it worked like a charm.

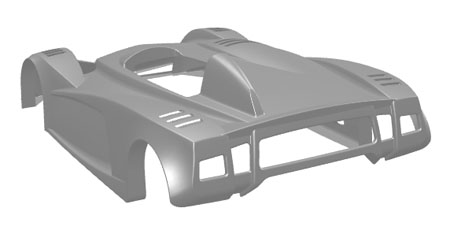

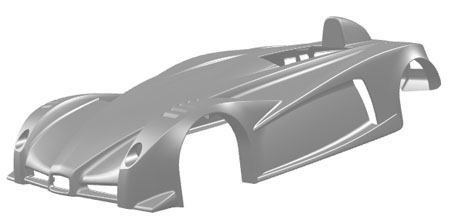

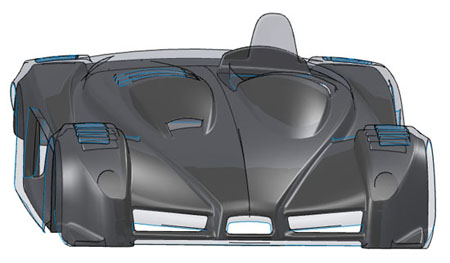

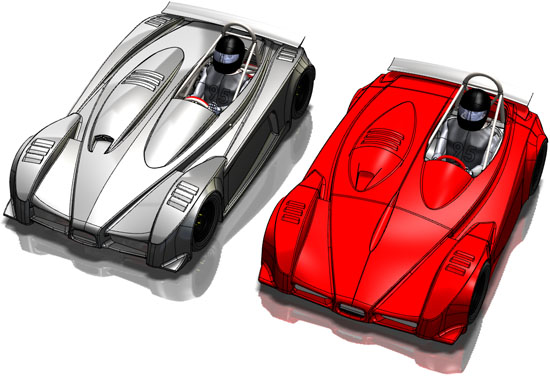

Just rolled the lift out into the street, plugged in a long extension cord, raised it up and rolled the plug on its casters into the trailer. Now we have more room to work on things, not a moment too soon. If only someone would buy the Atom already... 04/01/10 One of the things I've learned in all the years is that if you look at a design and something bothers you about it, it's just going to bother you more and more as time goes on. It's a good reason to leave things be for a while, put a couple pictures on the wall and stare at them every now and then. After the initial 'all is good' wears off, you start picking it apart and things pop out that need fixing. Of course if the tooling is already done the fixing has to be put off until version 2.0 some time down the line, but if not then there's the opportunity to change. And so it is with the dp1 (well, ok, version 2.0 of it). As the engine delivery draws near and I'm in dire need of a break from all the other more immediate projects, it's a good excuse to come back to it and tweak stuff. Not done yet, but below are some before (light grey) and after (darker) pix. The changes are subtle but they matter to me.

It's all about how the various shapes and lines interact. Very subjective and I know that some things I see as an improvement others may consider a step backward but that's inevitable. Anyway, lest people think I'm putting dp4, dp2, GT/LT uprights and a couple electric projects on the back burner - I'm not. In fact I just wrote and filed another patent app this past weekend, wrote and filed a federal grant application three days before that (not holding my breath since I'm not a failed wallstreet gambler but it's worth yet another try), made several new drawings and sent them out for quotes, followed up with several vendors, did some sales-related stuff... Good thing I'm a stereotypical Gemini so multitasking is actually fun :). Some good progress on dp4 too, will post that shortly. 06/08/10 A birthday present showed up for me, two days early... :)

08/24/10 Lots of other projects have gotten higher priority and so the dp1 has been on back burner this whole time. But now we're amidst setting plans and goals for next year and this car is very much a part of them. So progerss will be made shortly. In the meantime we pulled the V8 from the shelf and test-fitted the exhaust. 430 hp is easy to handle! :)

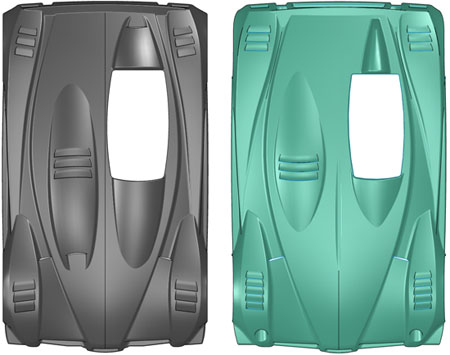

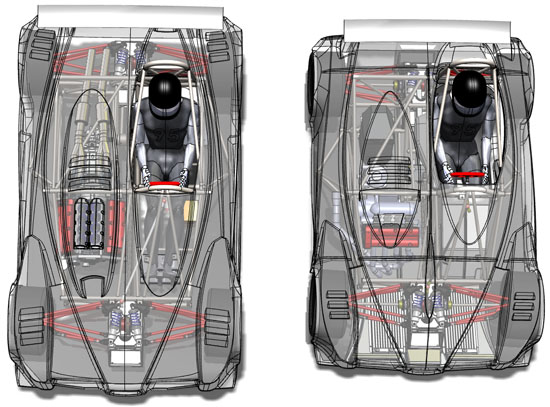

We'll have the engine sit there for a bit, it's a good reminder that there's work to be done. Plus it's a very cool piece of machinery to look at. 09/19/10 (updated 9/21) The big news is that we finally have a bonafide dp1 customer, money down and all. Shooting for early spring delivery. So now this project moves from back burner right into the frontline mix (joining dp4, dp1/e and a number of client projects). To that end I spent the weekend applying much of what I've learned from the dp4 to this design. The list is long, some of it is obvious and some subtle. The car is now slightly narrower, rear deck is 3" lower, nose is higher and has larger air intakes, engine has moved forward and towards center, driver moved towards center as well. Weight distribution is now dead-on side to side and 3% rear bias. Here's how the new body design (dark grey) compares to the previous version (green):

Yes, the car will have a provision for lights but smaller 50mm projector units. They're just not in CAD yet. Of course the more significant changes are underneath with a whole new chassis which is more in line with the dp4. Except that the dp1 is longer and lower with a more reclined driving position made possible by the extra 12" of wheelbase. Oh yeah and there's the engine too :)

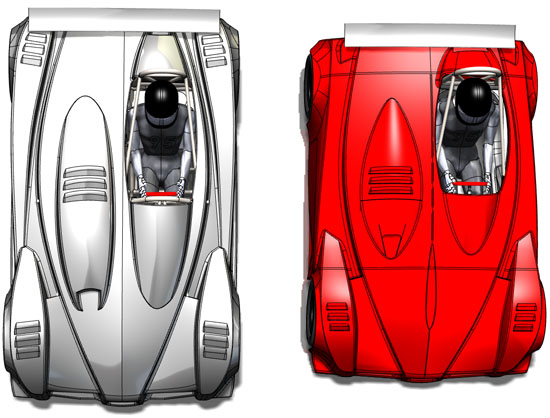

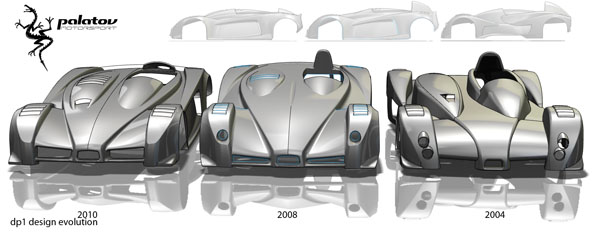

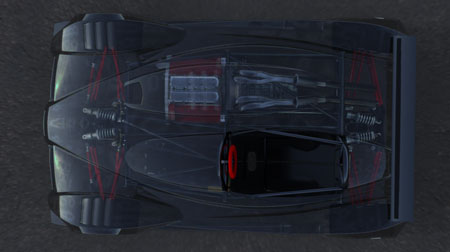

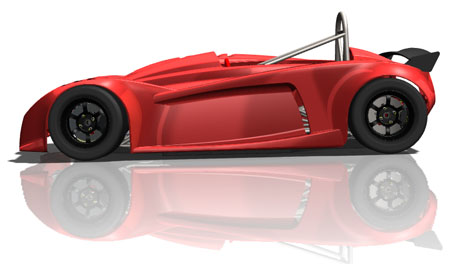

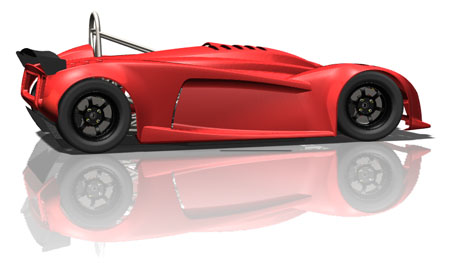

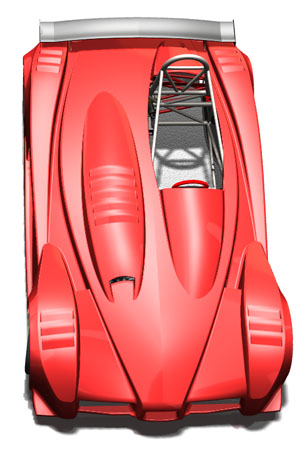

A few cool parts are getting ordered this coming week so it won't be too long before another update. Other dp1-retaled things are in the works too and I hope to have some news there soon. UPDATE: Just for fun I made a comparison of the first, second and third design iterations. Click for larger verision. 09/23/10 As cool as CAD screenshots are, sometimes it helps to have a bit more realistic visualization when tweaking the final body design details. To that end I've been trying out a free-trial version of Bunkspeed's SHOT program. It's a little clunky at first and does require good hardware but once you get used to the user interface producing rather amazing results is easy and quick. Here are some samples (click on each for larger version). And of course in the computer it's possible to do something that would be very hard in real life: 01/11/11 The dp1 is moving forward in earnest once more. Getting ready to release the CAD files to machining for making the plug, then mold and first bodywork. Simultaneously working on the new underbody and chassis.

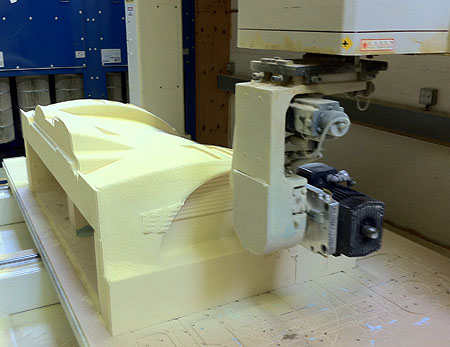

The rollbar design is still going to change, as will the floor under the nose. But it's getting there. Being as used as I am to the dp4 proportions, this car looks rather sleek to my eye. Long even. This is despite an 80" wheelbase (same as classic Mini!). I'm really looking forward to finally seeing this beast in the flesh. And I know I'm not the only one :) 01/24/11 This is where things get moving. The plug for the dp1 bodywork is being done locally at Willamette Pattern Works. They were able to start right away and it really helps that they are literally two blocks from our shop. This means we can just walk over and check on progress anytime. Which is what we did today. The plug is being done in two halves and the nose section was started about 5 days ago. This is what it looked like Friday:

And this is what it looks like today:

The blank for the tail section is already built.

Yes, finishing the complete plug will involve adding additional reinforcement on the inside to make sure it doesn't deform under vacuum when the mold is made. I'm finishing up a chassis design for a customer right now and when that's done (couple more days) the dp1 chassis will get wrapped up and sent off to get the tubes CNC'd. Computers are very useful indeed :) |