|

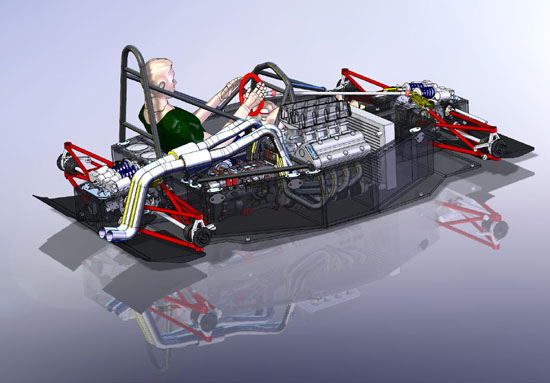

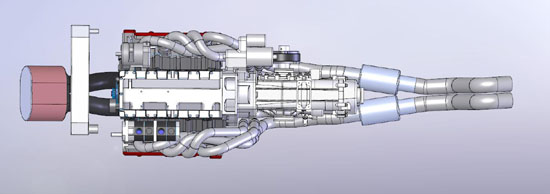

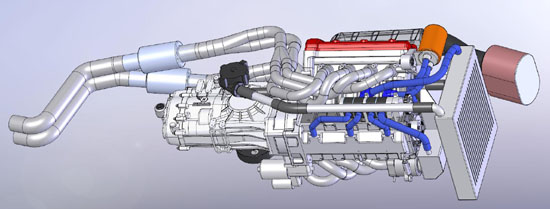

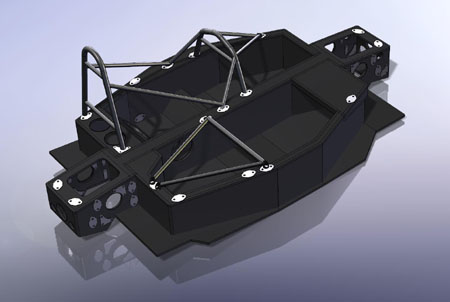

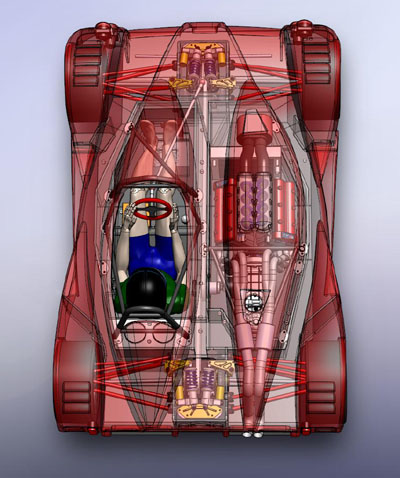

03/30/08 The chassis is nearing its final form. Perhaps the most challenging part is figuring out the hardpoints that will allow mounting of the various components and ensure proper load transfer to the composite. This is further complicated by the fact that the goal is to be able to mount several very different bodies on the same basic chassis. Engine/gearbox mount is another trick, seeing how the output shaft will see as much as 1,500 lb-ft of torque on it. The engine combined with the gearbox only weighs 330 lbs so if not properly tied down they'd just spin inside the chassis as a unit, which wouldn't be good. Supporting the weight is irrelevant compared to accommodating the drive torque which is not necessarily intuitive. But I think I have it now (no the picture is not final but close).

For an example of the range of bodywork that will be possible here's a picture of the 'classic' Mini body. Yes, the wheelbase is the same (on purpose).

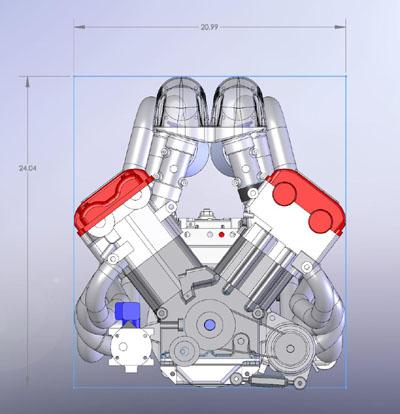

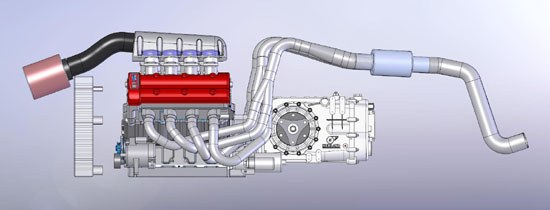

In this setup the driver will sit more upright obviously, which will make room for a passenger in tandem. That would be a scary ride. People keep asking me if the dp1 will ever be street legal. With the racer bodywork - no way. Nor would you ever want to drive it on the street in that configuration for countless reasons. However, as a bonafide replica of a 1964 Mini, in some locales it would be possible to register it under the 'hotrod' laws for limited street use. It still won't be legal in the normal sense of the word but it would be streetable. And with the upright driving position combined with increased visibility of the Mini shape it would be more realistic in the street environment. Well, as realistic as a 1,000 lb, 400+hp, AWD classic Mini can be :) Other replica bodies that come to mind are Fiat 500 and bugeye Sprite (again, same wheelbase). And of course this opens it up to custom coachwork of all kinds. In other news, the engine has been ordered (it will now be a 3.0L with I'm guessing around 425hp). The gearbox details are being finalized and should be ordered shortly. Other pieces are coming together as well. The somewhat ambitious goal is to have the v8 dp1 driving this summer. We'll see. 04/04/08 Among all the other things I'm working on the dp1 is still getting some attention. What helps is that I can leverage the things learned here on other tasks. Sooo.... The exhaust and intake are done, pretty much. It may look like I intended the bodywork for this but in reality I didn't know the V8 existed back when I designed it. It is small part luck and mostly a very tough packaging job. But it's coming together. Same K&N filter as I put in the Atom which I know works. Mufflers are 4" Magnaflow stainless 'race' units - no room for anything else. Hopefully that'll be quiet enough. I can replace them with high-flow catalysts if a more eco-friendly version is called for. Either way, a lot of shielding will be used.

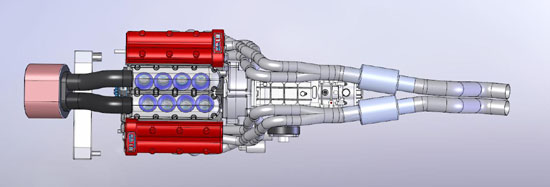

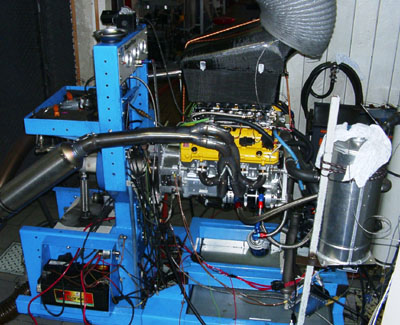

Actually the exhaust was a real hassle but the experience designing the Bikini install really paid off. It was almost easy.... No, not really, but I did get it done. All the primaries are equal at 24" and the secondaries are equal too. And the entire thing does not add any width to the engine which is critical in this particular install. The overall package is 21" wide and 24" tall. The combined weight of the engine assembly complete with gearbox, exhaust, intake and all accessories is around 390 lbs.

04/17/06 Lots of projects going on, I'm juggling about five of them. It's actually nice because when I'm waiting on something or just have brain block on one I can just switch to another one and keep going. So in all this activity, a little more progress has been made on the dp1. A while back I was looking at the drivetrain design and realized that the 'guibo' rubber donuts I used on the prototype won't cut it for the v8. The original parts, from a BMW 3-series, were actually quite nice - small, light, available and inexpensive. But now the peak torque coming out of the gearbox is 1,500 lb-ft so I had to find parts that will work. Fortunately, BMW keeps upping engine sizes in its cars and in fact the 550i does produce a maximum of 1,501 lb-ft torque out of the gearbox (owing to a 4.17:1 first gear). Cool. The part was ordered several weeks ago and showed up early this month, I just hadn't gotten around to doing anything with it until now. First picture below shows the 3-series donut, second is the new part. It is as close to scale as practical.

There is actually quite a bit of engineering in the new donut. A close look reveals that it's dual rate (or triple rate, actually) and asymmetrical with respect to direction of rotation. I suspect BMW spent more designing just this one part than I will ever spend on the entire dp1 project. But now I can buy these for $128 retail so that is good. Another bit that got done is the bellhousing to couple the Hewland to the Hartley. And, of course, with everything being connected to everything else, I had to tweak my original dimensions to provide more clearance between exhaust and the new, much bigger, guibo. It's turning out to be a pretty tidy package though.

A bunch of detail work remains on the chassis (learning a lot there), ditto for the drivetrain. After those are off and being made I'll get on the interior and controls. If this were the only thing I'm doing and I could give it near full time, it would still be a stretch getting everything done by summer. As it is... well, have to keep pushing forward. The other projects are quite fun too, I just can't talk about them here :). 04/27/08 Weekends are just like any other day, except that I feel better about working on the dp1 instead of other projects. So this weekend saw some more progress. I've been working on the details of the new chassis, and of course I had to redesign the engine mounts a few times. Then I remembered how much of a pain plumbing was on the prototype and on the Atom, so I decided to do it in CAD this time. Good thing, too - ended up redesigning engine mounts yet again and tweaking the chassis substantially to provide clearance for everything. Bikini is proving very valuable indeed - not only as a demonstration of how effective the V8 is but also as an exercise in packaging. The lessons learned there are really paying off now.

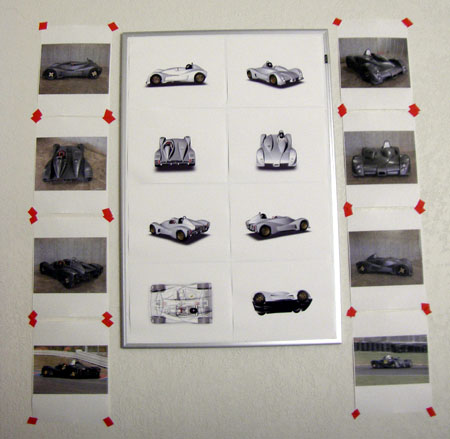

Speaking of the V8 in the Atom, every time I drive that car I get more excited about it. The thing is just awesome. The Exige REALLY needs one of these motors. I did some measuring and yes I'm pretty sure it'll fit. Next winter's project, most likely - but no, not with THIS exige. Also while on the subject of V8s, both Ariel and Caterham recently announced versions using a supercharged RST (see the M5 pages in the PAST section). Their prices are insane - upwards of $250K?! And there's no way they're going to put 500 hp down in a 1300 lb car with only rear wheels driven. But hey, it validates the market. Just hope the RST doesn't blow up with supercharger like it's reputed to do normally aspirated :) Interestingly, both companies released photoshopped pictures instead of real ones. I wonder if that engine actually exists yet. Time will tell. The above leads me to pricing. Looking at the BOM and looking at the market out there, the original $125K for the dp1 is starting to look a bit low. So the new MSRP is now $150K complete with a 3.0L V8 (425+hp), AWD (so it can actually use the power!), and a track introduction to the car at PIR. 07/24/08 The lack of updates recently might lead one to believe there is no progress - not so. The new engine is on order and being built (a 3.0L version with more ponies, just in case 2 lb per horsepower is too much of a burden). Composite chassis panels are due in a few weeks. Custom gearbox from Hewland has been ordered and is due shortly. And so on... (there are some neat peripheral dp1 developments too but I can't talk about them yet). Much remains to be done, no doubt. Yet much is being done. I'm busy to the point of pulling an all-nighter Sunday night. And I thought college days were over... glad I can still do it though :) When I was posting today's Atom update there were a lot of pictures of some of my other projects on the camera. Too bad I can't post them - some would get a kick out of those, others wouldn't understand :) All in due time. 08/19/08 (updated 8/20) I was doing some CAD renderings of the planned additions to the dpcars model lineup (details will be available soon but not just yet) and this reminded me of something. Long ago, when I finished the dp1 design in CAD and sent it off for the bodywork molds to be made, I printed out eight computer-generated views and hung them on the wall in my house as a milestone of sorts. A couple years later, when the prototype first ran on the track, I took actual pictures to match those views and taped them on the wall next to the computer-generated ones. Another milestone.

Now I have some more virtual views on the wall awaiting eventual real-life photos to go next to them. It'll be fun! :) Speaking of computer renderings, I've been demoing a rendering package called HyperShot from Bunkspeed. After watching the online tutorial (because user interface is non-intuitive but quite easy once you learn it) I was able to quickly generate some test images of the dp1 and other things. The dp1 ones are below.

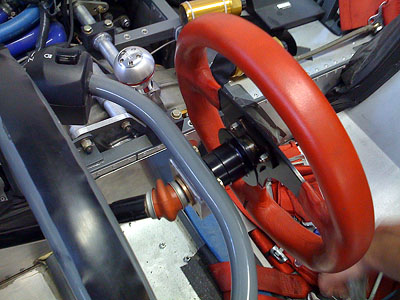

Pretty cool, and that's spending all of 5 minutes on setup. It can be much better than this. A nifty tool that I might consider getting. For example I was able to insert an extra dp1 into an earlier pic and it looks reasonably convincing (yes, I know, it's not perfect and won't fool anyone - well maybe some - but it does illustrate the point). Click for larger version. 08/23/08 Well, enough of the virtual and back to reality. Lotus day is coming up next week and it's always a good venue for strange machinery so I'm thinking the dp1 proto needs another outing. It will be a good place to test the new spring rates that were determined by simulation (a topic for another day). So the springs are on order and should be here monday. But in the meantime a number of other things need taking care of. The first was the steering - I had used a nylon support for the steering wheel and it turned out way too flimsy. So Jared and I made a proper aluminum-and-bronze one. Much better.

The next thing is a better solution for dealing with the brake dust coming off the front brake. I've basically decided to bite the bullet and route it out under the car. To that end the car had to be raised and a hole cut in the underfloor (this is also a test for the v8 chassis solution).

Now I need to make some ducting and then I'll be ready to deal with springs and such. Will need to check the chains also. All that will have to happen tuesday or wednesday. In other news, the composite panels for the v8 chassis are being cut and the v8 itself is coming along. Last night I got an email from John saying that he thinks with some head work and cams he's pretty confident he can get a bit over 500hp from the 3.0L and he also wants to get some numbers on his new dyno setup so would I mind terribly if he bumped the power on my engine? Uhm... I really had to think hard about that one - for about a millisecond! DO IT!

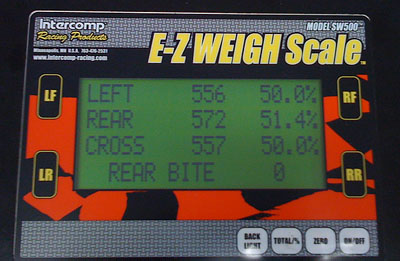

So now my targeted-at-850 lbs car will be getting a bit over 500 hp. Call it insurance just in case it turns out a few pounds overweight. Can't chance missing that 1,000 hp / ton mark! 08/29/08 This has got to be one of the most trying summers in recent history for me and today was one of the most frustrating days in it. I've spent the last two days working feverishly to get both the dp1 and the atom ready for the Lotus day. Replaced the dash on the Atom, got it to actually work with the ECU so the revs don't freak out above 8K, did some wiring, changed gauges, etc. On the dp1 I solved the 'driveline drag' problem (turned out to be a stuck front caliper), finished the front brake ducting and did a myriad of other little tasks that needed taking care of. Setting up the corner weights, the car with me and some fuel in it is exactly 1111 lbs.

This morning with a bit of stress over logistics we got the dp1, the Atom and the Mini to the track with the help of some friends and my mother-in-law. So at 8:30 AM everything was set:

The dp1 was the first one up. The tires, never having heated in the first place, did not get any better for having sat for over a year and started out pretty slippery. I also started a ways back in the pack and it took me a few laps to pick through them all. Fortunately I ran in race group so it was open passing and the car passes everything with ease. On cold tires it is pretty 'lively' though. The new spring rates (more than double the original, at 500 lbs vs 200) are actually quite good and about right. Below is a shot of old vs new spring. Quite a bit beefier.

Needs more shock, definitely, but that's not a surprise considering that the only thing I did to the shocks is turn up the comp and rebound adjustments up to max instead of having them revalved. Just as I get clear of traffic and the tires are starting to almost feel like they're warming up, braking and turning into the chicane WHAM-GRIND-SLIDE!!! I end up skidding over the 'tiger's teeth' curbing but manage to stay on the track and park it. It is quite obvious that the right front corner is not being supported by anything but the underbody on the pavement. The session is stopped, track workers come out and help me push the car to a safe spot. Even though the right front wheel is at a crazy angle, when rolling backwards it straightens itself out and kind of rolls along. Upon close examination, it seems the 1/2" AN bolt that connects the lower suspension arm spherical bearing to the upright pulled out. The bolt was loctited AND safety wired, and it was bolted into a full steel threaded insert ('Timesert', similar to a Heli-Coil but a solid insert instead of a coiled wire). Well, the chunks of the insert were still on the bolt, it just ripped the whole thing out. Wow. Not something that I would expect. Lee Stohr looked at it and said 'hmm, this is how we do our DSRs and it's done all the time - except for the insert'. I see. I guess a big part of the problem here is using AN fine threads into aluminum. I thought that these inserts would provide a proper patch of steel for the bolt to screw into but I've had nothing but trouble with them. Misthreading in other locations and now this. OK, another lesson learned - only coarse threads in soft metals, inserts or not! And of course a locknut on the other side would have been very useful. One might say I got away pretty easy here - no impact with hard objects or other cars, just put the car back on the trailer and switch to the Atom... Well, if it went like that it would probably be OK. The dp1 did go back on the trailer (had to wait till lunch) and went to the shop. I'll have to decide how much effort to put into the prototype given how far along the production car is. At the very least I need to account for all the lessons learned. So, on to the Atom. The plan was to take a couple laps, come in and see if any oil is finding its way into the catch tank. So off I go. Having learned to watch the mirrors for smoke I'm not surprised but defintiely not pleased to see blue cloud behind me after just half a lap! DAMN! So I pull in and it seems the problem is worse than ever before, so all my efforts not only produced no gain but made things worse. Ugh. There is no way oil should be finding its way that high up and through all the labyrinths, but it does - by the barrel. It seems that plumbing the drain from my overflow tube into the upper scavenge line was a mistake. At over 8K rpm there is quite a bit of foaming and the foam just gets pushed up the drain tube instead of into the tank. So now I need to pull the tank once again and add yet another fitting to it for the drain. It has to be below the foam level but above the pickup to avoild introducing air into it. Oh joy. Will that solve it? I don't know. Maybe there's another issue at play here. John Hartley keeps saying I need much more oil volume but there just isn't any place to put it. Today I learned that Brammo had a lot of issues with their drysump system too so I'm not alone - maybe I'm just alone in being so public about the problems I encounter. It's worth it if someone else can benefit from all this. Anyway, after a combined total of seven laps I was done for the day. M was running the Mini and I suppose I could have driven it but my heart just wasn't in it. Ah well, just consider it education. There were a couple other Atoms in attendance, one having come up from California.

A couple of years ago a discussion came up on the Atom forum about lap times and someone stated that 1:25 should be possible at PIR in an Atom. My reply was that it was a very tall order but if anyone could pull it off I'd buy them dinner. Darin, the driver of the red car in the picture, finally decided to take me up on it. And not only did he get under 1:25, he did it with room to spare: 1:23.15 on the datalogger. Nice going! Yep, the dinner is on me tonight. With no successes of my own to celebrate today, might as well celebrate someone else's :) 10/09/08 Even though I haven't posted an update in a while, much has taken place. The composite panels for the chassis are here. Well, actually they showed up, I found some issues, shipped them back, issues were fixed and they're here again.

Assembling them into an actual chassis will have to wait for a few more things to come together but there's progress on that front too. Everything takes a lot longer than expected but as long as I don't give up and keep going, things eventually do get done. The developments are actually quite exciting but it's not time to talk about them yet. What I can say is that the dp1 will get several siblings soon and a couple of alternative bodywork options will be available along with the original :) As a confirmation of the value of the experience gained in this project, tasks that took several months the first time through now take weeks or even days. So the whole project has been an excellent investment indeed and will only become more so going forward. In other news the custom gearbox is done at Hewland. I need to arrange for shipment so hopefully that'll be here in a couple weeks. With regards to the prototype's recent mishap, the damage is very minimal and work is underway to make the repairs and heed the lessons learned. Won't be done in time to test it in what's left of this season but done it shall be. |

.

.