|

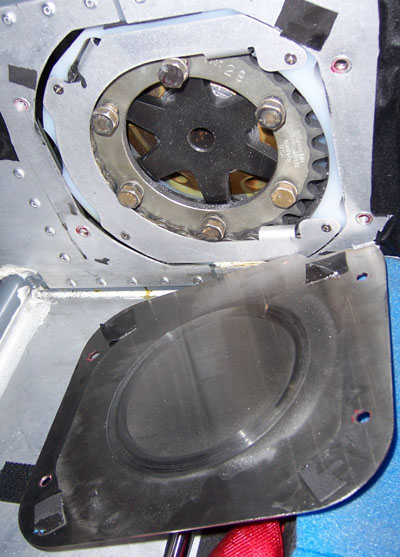

4/16/07 One item that should be of interest to many people reading these pages - Kurt, the designer and builder of the Kimini project that I've mentioned before, has finally completed his book about the experience of building his car. If you're wondering how one can build a car from scratch without 3D CAD and CNC machined tooling, this book will answer most if not all of your questions. And it is a great illustration that there's more than one way to go about carbuilding. Kurt's approach is quite different from mine and is readily accessible to a greater number of people. People with enough determination and persistense, that is, but then that's what it takes to finish a project of this magnitude no matter how you go about it :) Kurt took about 10 years to complete his. What matters is the will - the means can vary. Click below for details. Now back to my own efforts - I pulled off the cover on the chain sprocket to see what the issue is. Quite a surprise inside...

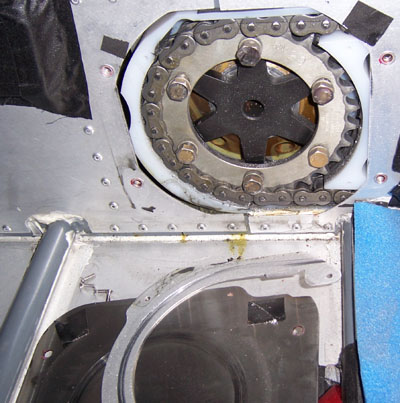

Basically, all six bolts securing the sprocket to the drive flange have backed out. I'm really glad for my belt-and-suspenders approach to the covers. The inner chain cover kept the sprocket from coming out all the way and gave the chain soft aluminum to rub against, the outer stainless cover kept the bolts from backing out ALL the way and resisted their advance towards my knee. No wonder the cover was getting hot. So, no major damage but I gotta wonder how all the bolts could do this. I thought I had Loc-Tite'd them and torqued to 20 lb-ft... but maybe this is the one sprocket I overlooked? No paint marks on the bolts which is indicative of this being the case. Have to make sure this doesn't happen again. Another reasonably cheap lesson. Whew. Also, the new tires are here so now I need to go pull the wheels off and take them to A-N-T to swap the old set out. If anyone wants a hardly-worn but slightly heatcycled set of AS03 Hoosiers in 225/45-13, let me know. They should work just fine on a heavier car and still even have the 'shadow tread' on them. On the virtual front, I finally got around to replacing my aging media computer with a new system, with a modern graphics card (nVidia GeForce 7600GT). I just put the thing together from parts. It's been a while since I've done that so it was a welcome blast from the past. Technologies have changed a bit in the meantime. Dual Core, SATA, DDR2, PCI Express, the demise of the floppy disk... Most importantly, the new video card has HDMI output and so can drive the TV digitally at its full resolution - 1920x1080. Besides looking great with games and DVDs, this makes it very suitable for CAD. So now I can design the production dp1 parts while kicking back on the couch....

Ah, the wonders of modern technology. Good stuff. And speaking of virtual and technology - this is something I never want to do in RL (knock on wood!), but I tried to see just how spectacularly I can crash in LFS. Below is a clip of my 'best' (or is it worst?) effort: Note the helmet protruding through the roof in the end. OUCH. Of course in the game I could just keep going (the car drove pretty funny after that though, LFS does keep track of damage to a degree). It's a shame that the damned autofocus on my video camera keeps hunting, you can only see in a couple spots just how amazingly well the whole scene is rendered in the sim. Yes, I know, I can get a direct capture program but it's not a priority right now. This is just for amusement, because it's sometimes fun to play in a world of no consequences :) 05/08/07 Another test day for the prototype. This is a Grand Prix Imports trackday and attracts a lot of exotica. Perfect weather helps in that regard so it's fun to wonder around the parking lot...

My day started the previous afternoon, when I finally realized it might be good to actually prep the car for the track. I even left the BMW trackday early to get a head start. The plan was to replace the rear chain and to change the oil (the latter procedure is quite involved and requires the removal of the floor). Floor removal was also something I wanted to do for general inspection and maintenance. It is not a trivial procedure on the prototype - this whole arrangement will definitely change in production!

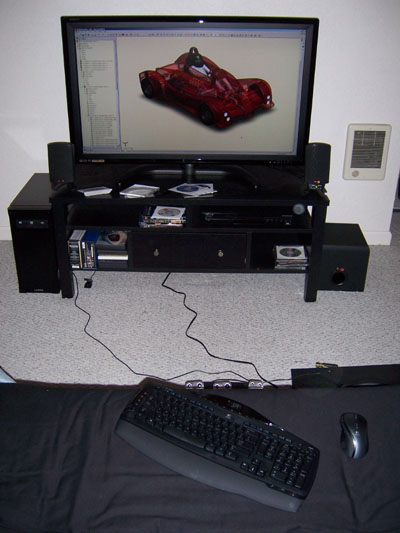

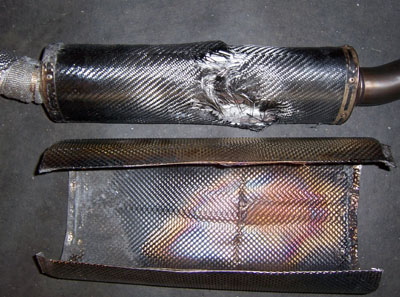

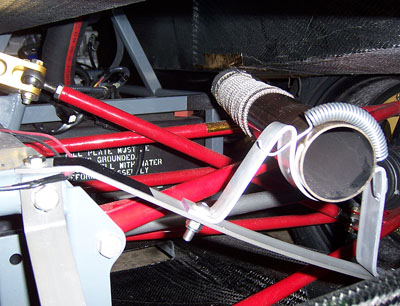

This took a while and involved dremeling and drilling out one of the rivnuts attaching the floor to the frame. At some point in the evening Joe stopped by to help for which I am quite grateful. We examined the chain and reached the concensus that it was not damaged and could stay on. Fortunate, since that would have been a lengthy procedure in itself. Around 10pm Joe went home leaving me to finish the work on my own. As I was getting ready to put things back together I noticed something odd about the muffler. A closer look revealed this:

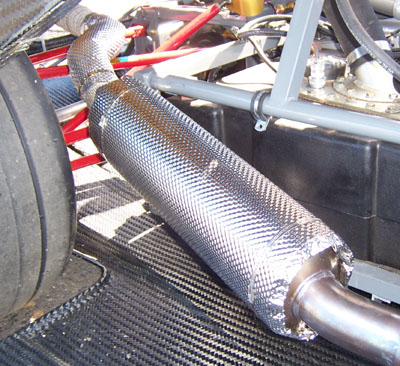

Yep, the thing is buring up! If it burst into flames it could potentially be quite unpleasant. For a bit I considered scrapping the plans for the track outing but then decided I was not going to be held back by such minor challenges. So I came up with a stainless steel wrap for the muffler, using the same material that I used for shielding the exhaust on the Atom. Turned out pretty clean (and fortunate, as fate would have it).

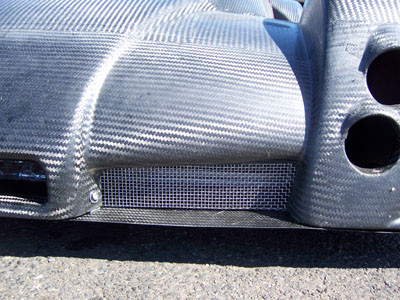

So at 1am I finally decided to go home and get some sleep, returning at 6 am to finish putting things back together. I also noticed that the radiators are getting chewed up by debris so it was necessary to fabricate some grilles.

By 8 am I was nearly done and Joe and Craig showed up to help me load the car on the trailer. It's great to have some help every now and then. What I really need though is a crew chief or something like that, as I ended up forgetting a number of things and having to either improvise or ask people to get them for me at the last moment. My broomstick hood prop is a good example and drew some comments :) Oh well, it's hard to do the work and stay on top of the details too.

Eventually I made it to the track although I did end up missing the first session. Hooked up the camera and GPS, and went out in the second one...

About 4 laps into it I get a 'meatball' flag - mechanical malfunction. Quick check of the mirrors - yep, smoke. The muffler is burning. Actual flames out the tailpipe according to people I talked to later. So I pull off, watch the smoke pouring out the car and wonder if I should pull the fire system handle. Nah. I know what it is and I prepared for just such a contingency by wrapping the muffler in stainless steel. And sure enough, the smoke goes away and I drive back to the pits with no issues. An inspection confirms that everything is OK and the shielding worked as intended. Upon some reflection I conclude that the muffler only burns if I use over 8K rpm so I decide to keep it under 7.5K for subsequent sessions. Just in case I discuss this with corner workers and they're good with it - only bring me in if it's REALLY bad, some minor smoke is not a problem. So the next two sessions I short-shift at 7K and focus on increasing corner speeds instead. This goes reasonably well except I STILL can't get any heat into the tires. Sadly, it seems actual slicks are the only option for the car. Even A/X compound DOT Hoosiers only heat up on the surface. That said, the car felt like it had plenty in reserve so while I did a best of only 1:29 flat (ok, 1:28.99 :) it was basically a walk in the park. I'm just not ready to push harder than that. Yet. Even so it was a lot of fun and I was passing pretty much everyone. Nobody passed me even once. I even came up with a marketing slogan: "dp1: OWN the track" :) Yeah, yeah, I know, gotta finish the production design and build a couple first.... :) I tried a new camera angle and the result is kind of neat. The two movie clips are fairly large due to my new resolve to render things out in high res. The first, a recording of the 1:29 lap, is about 20M in size - you can see it here. The second is a compilation of some highlights, about 17M in size - here. Unfortunately the sound is pretty horrible in both videos. I had put tape over the microphone to reduce wind noise but it is still the dominant sound. I'll have to experiment with setups to find something that works better. It was a warm day, as much as 85 degrees and this served as a good test for several things. One is the cooling setup - both oil and water stayed at about 190F which is kind of on the cold side actually. Except of course for the fact that radiator air enters the cockpit at the moment, so I get a heater whether I want it or not. It was definitely toasty but not outrageously so and I did not experience any abnormal discomfort during the 20-minute sessions. I'm getting more used to the car now both from performance standpoint and as an environment, and the cockpit now feels nice and cozy. After the last session I actually was reluctant to get out and was glad when people came over to talk about the car so I could just sit there for a bit longer. Silly, I know. Works for me. :) Next pair of trackdays is May 24 and 25. I REALLY should get Bikini done by then. Frankly it would be a stretch, knowing what still needs to be done, but damn. The car was supposed to be done a year ago. So it goes, I guess. 05/16/07 Mostly this update is to let everyone know that the Hartley V8 now has its own website: www.h1v8.com. The engines are now being delivered to a few OEM type projects and plans are underway for general availability.

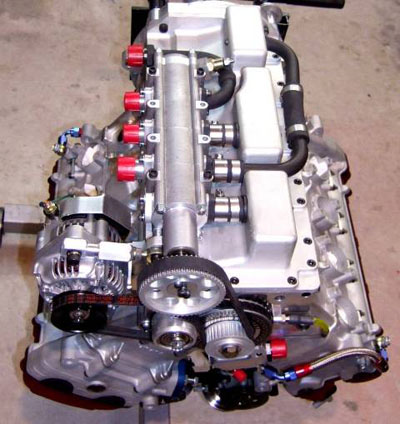

The last picture shows how small the engine is, sitting next to a Ford Zetec 4-cylinder. In my own news, I'm getting ever closer to firing up the one I have in the Atom... Fun stuff. 05/19/07 The next planned track outing is Friday, the Lotus Club event on the 25th. To that end I did a basic maintenance check on the car. The chain sprocket is staying on. Good. The muffler is still wrapped in stainless shield. Good. Or... Wait, something's not quite right. A closer inspection shows a tear in the shielding. OK, take it apart and see what's really going on (this is a lesson learned from several earlier incidents). I knew it wasn't going to be pretty.

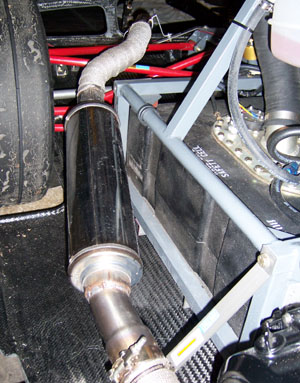

Still, the amount of damage to the shielding is a surprise. I didn't think the exhaust heat was going to be burning through stainless steel. The curious though not entirely unexpected thing about the muffler itself is that the resin in the casing is what's burning away. The carbon cloth is essentially staying intact from heat except where it's physically being blown away by gas flow. The glass packing is melting, of course. So now I have essentially two days to find a solution, order it, receive it and install it. As an experiment I fired up the engine without the muffler, just to hear how bad it is. Bad to the bone. The sound is glorious, just possibly a bit too loud for these noise-sensitive times. But if it comes down to that, for just the one trackday in my book it's a valid option. It'd make for better sounding videos, definitely. We shall see. 05/23/07 The muffler showed up today (a day late) so I spent the afternoon installing it. Strange for me not to be doing this at 2 am before the trackday :) After some searching around online the muffler I chose is a simple stainless unit from Magnaflow. Cheap, too, at $60. After ordering it I got emails from a couple people suggesting this very solution so it seemed promising. The Magnaflow is a straight-through design and is 4" in diameter. A bit smaller overall than the Ducati can it's replacing.

After cutting off the tailpipe from what was left of the old silencer I trimmed the new one, test-fit the assembly in the car, then tacked it together and finally welded the whole thing up. Pretty painless overall and my welds are starting to look better. The install back in the car went smoothly. I did have to fabricate a new support bracket for the tailpipe but that didn't take too long.

I also ended up adding some shielding around the new muffler, what with its proximity to the fuel tank and all. The shielding is a 'composite' - one layer of stainless against the muffler, then two layers of aluminum. Hopefully this will keep temps in check. The sound seems a bit louder than before. Pretty cool.

The other item in preparation for Friday is to swap tires again. As the picture below shows the Hoosiers are just not getting any heat in them. So yes, I now have a set of brand-new A6 Hoosiers in 225/45-13 for sale. Sigh. The new tires are Avon race radials (bonafide slicks), they should be here tomorrow.

Since the brakes are inboard the dp1 looks a bit odd up on jacks, like there's something missing. It's a good illustration of why the unsprung weight is so low :) |