|

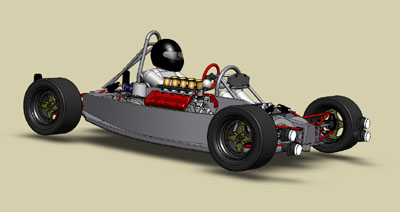

10/22/06 Finally. The big track debut. I had pushed pretty hard to get the car out on the track before the season is over and I made it. Just. How did it go? Overall, better than expected. My goal for the day was just to find out if it works at all and to get a list of things that I need to test/debug. In terms of lap times I was aiming for anything under 1:35 as being satisfactory for the first outing. In fact I got under 1:30 in only the second session, with a best of 1:29.6 which comes within half a second of the best lap I've ever run here (in the Westie). The advanced group was pretty crowded and there was quite a bit of traffic, so I only got two clear laps the entire time (a 1:29.63 and a 1:29.64). There is PLENTY more to gain in this car (see GPS analysis below). I'm only getting started, in more ways than one. And it's a fun start :) Right now I'm going quite easy on the brakes and corner speed, short-shifting at 8K rpm on acceleration. Here's some video from the nose-mounted camera (19M file) And here is some from the helmet cam (15M file) Keep in mind that the camera sits on the helmet a couple inches below eye level (to clear the visor - in fact you can kind of see the camera in the first picture below) so the actual view forward is much less obscured than what it appears in the video. It was never an issue when out on the track or just driving around the pits. The car attracted quite a bit of attention and several people had made the trip to the track just to see it run - thank you all for the support! Pictures below courtesy David Paris. (click for larger versions) The weather cooperated perfectly, it would be hard to ask for better conditions. Unloading from the trailer in the morning it was still a little chilly, around 50F, but quickly warmed up to a high of around 60F with no wind and a cloudless sky. A great Fall day. Tech inspection went without any issues.

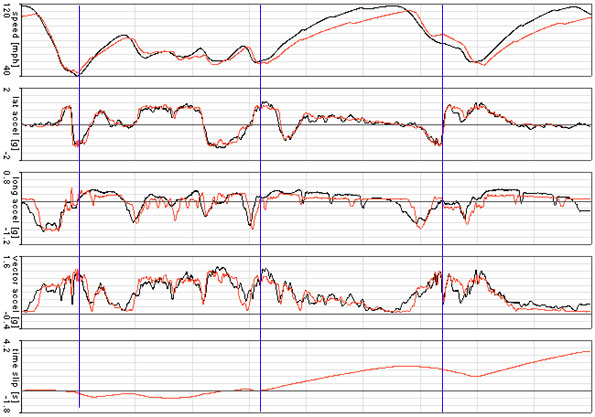

I then spent some time hooking up all the electronics so I missed most of the first session, which was just as well. Did get a coulpe complete laps in traffic, pretty slow, just to see if there is any evil behavior at speed. Detecting no weirdness I was ready to open it up a bit in the next session. There is definitely downforce - the car feels a bit edgy at 75-80, wanting to 'walk' a little on irregular pavement, but passing the 100 mph mark it starts to feel more and more planted. I'll have to hook up sensors to the suspension to quantify aero forces but overall looks like another reasonably successful guess on my part. There is also quite a bit of drag, not as bad as the Westie, but I definitely need to get passing done early out of corners where the traction and the favorable power/weight are a huge advantage. Power can be applied early and liberally mid-corner with no ill effects on handling. The car just pulls strongly and cleanly out of the turn. I was very cautious with the brakes, not wanting to spin out here braking from 122 mph (my top speed for the day). So I took it quite easy with the braking. The new Wilwood pads are dusting a whole lot less but I can definitely smell the front brake going into the chicane! Once I add the interior airflow management panels over the winter this will change but for now I get to be quite intimate with the various airflows inside the bodywork. The air around the engine pretty much stays confined to the 'bubble' on the right side and exits out the back, as designed, but some of the radiator air sneaks into the cockpit. And of course some of the front brake air does too. It is nothing bad and actually on a slightly chilly day like today the warmth was quite welcome. About same as running the heater on a middle setting in a normal street car. Anyway, the brakes actually didn't do anything evil but I only used about 0.8g max and it is clearly reflected in the GPS data. Likewise, due to steering being a bit on the quick side (contrary to some people's concerns about it being too slow after watching the kart track videos), I took it easy charging into corners trying to concentrate on smoothly bending the car into the arc. In the helmetcam video above you can see I only use about 1/4 turn of steering in the chicane and about 1/8 turn elsewhere on the track. In the traces below you can see how shifting 'prints through' to lateral g on the back straight (between 2nd and 3rd blue lines). After I test a few different alignment settings I might consider slowing the steering down a bit. You can also see how conservative I am in 10-11 (third blue line), running almost 7 mph slower in the dp1 than in the MINI when it should be the other way around. Black set of traces is dp1 at 1:29.6 and red set is my best lap in the MINI on R compounds at 1:32.9.

The first obvious thing from above is just how much better dp1 gets out of the corners. I'm still shifting 2K RPM short of redline but using more or less full throttle. The power/drag ratio comes into play above 115 mph and so far the car is proving to be a bit more draggy than hoped for. CFD predictions were definitely WAY off. According to the simulations the car would have about 180 mph top speed with the stock 'Busa motor and it's looking more like 135-140 so far (actually I think SOME of the simulations predicted the higher drag, I'll have to go back and check). Of course there are mechanical losses too but still. All the better argument for the V8 :) The day didn't go totally without issues, of course, which is to be expected. Once up to speed the center diff is back to spitting oil, overflowing my catch can solution. Guess I'll need to use a bigger reservoir. This thing is a pain.

Another issue is that the temp gauge was reading full hot after the second session, even though it stayed firmly in the center throughout the first one. After everything cooled off turning the ignition on sent the gauge to the top again, so that leads me to believe there's a sensor/indicator issue rather than an actual cooling problem. The electric waterpump is working fine and all the parts of the cooling system are at equal temperatures. I'll need to get some sensors hooked up so I can actually log oil and water temps. The final problem, and it may be related to the temp sense issue, is that in the third session I got an ECU check light and the motor started cutting out at 7K rpm, then at 6K. Felt like a rev limiter so it might be the ECU trying to put itself into partial-fail mode. I'll have to tinker with that and see if I can get the fault codes out of it (need to put it into 'dealer' mode, I know how just haven't done it yet). So with all that I decided to call it a successful test day and packed up. Unloading back at the shop, there is a definite feeling of satisfaction :)

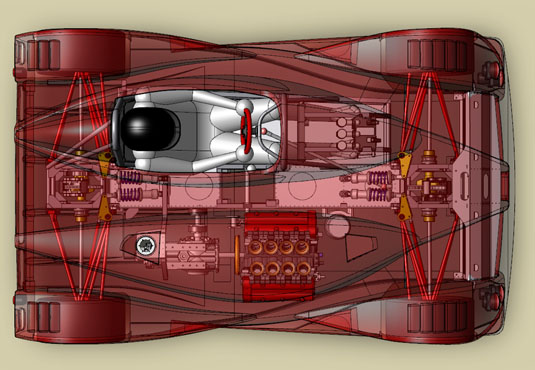

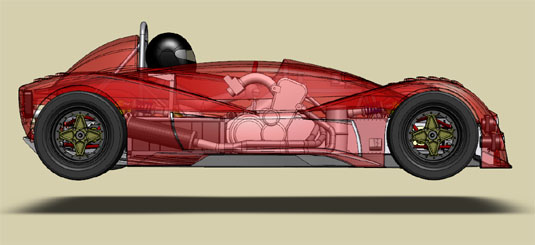

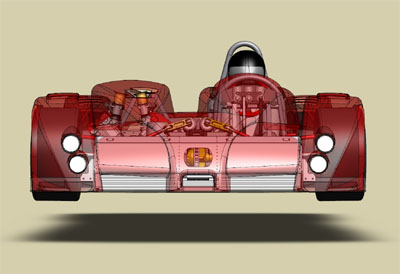

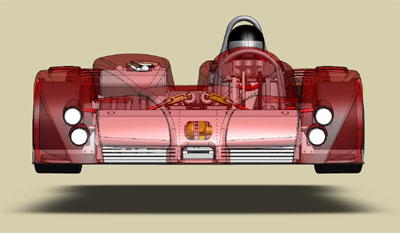

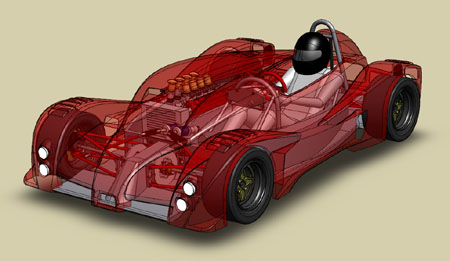

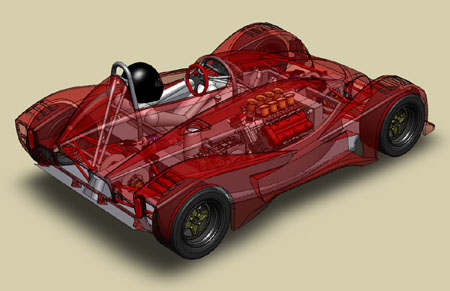

Now that the basics are known and the specific things to work on are clear, I need to design and carry out an extensive test program. Too bad the weather is not going to be conducive to this for the next few months but I have plenty of other things to do too. Interior body panels, mounting the headlights, wiring the turn signals and such, getting a VIN and a license plate, etc. And, of course, the substantial redesign for production starting with the brakes, chassis and drivetrain. So no shortage of things to keep me busy! Updates will be less frequent, of course, but I'll keep the progress documented as it happens. Whew. 11/09/06 It's been raining pretty hard lately (reminds me of how lucky I was to get decent weather for the last two trackdays of the year!). This means not much testing on the dp1. I did go through and figure out why it was cutting out on the track. Turns out the car was running out of fuel. I had filled the fuel cell to the cap previously but something didn't feel right about that - it went too fast. When I later tried to start the car it wouldn't fire. The handy fuel pressure gauge was showing zero, but the fuel was still half way up the filler neck. Odd. The pump seemed to be running fine and when I disconnected the hose it was basically pumping air - but creating some pressure even with that. So before taking apart the fuel cell (a messy business) I decided to think about it for a while. What could cause this? Obviously fuel was not getting in. There is a screen at the filler plate but it is unlikely that it would clog so suddenly and so completely. Then I remembered that there is also a safety valve that closes off the filler neck in the event of a rollover. Ah-ha! The foam inside the cell must have shifted and is pushing up on the valve, closing it. Then I thought that if this is the case, there should be a way to push it open from above. A short piece of fuel hose stuffed down the filler neck and poked around a bit in fact produced the desired result. Fuel went into the cell. The engine started and ran with no problems. Cool. It is something I need to fix but I can work around it in the meantime. So while the sky is dumping massive quantities of water on everything I decided to make some progress on the redesign for the V8. The transmission choice is down to two - JFR from Hewland and TXL200-5S from Elite. Both are 5-speed sequentials with reverse. Both have a pretty wide range of ratios avaialble and I already picked out the 'stock' ones. They are essentially identical for both. I don't have CAD from Hewland yet but Elite have already supplied theirs so I did a quick check fit in SolidWorks. The frame is still obviously from the prototype (I need to design the carbon chassis that will be in the production version) and I don't have a bellhoushing model yet but overall results are promising. Note how much lower the V8 sits than the stock Hayabusa mill. CG actually dropped 0.6" and moved to the right by 0.4". Overall weight went up by 30 lbs (because the center diff can now be removed). The placement is not final but close.

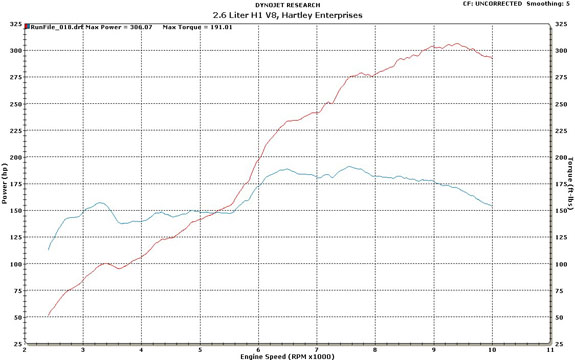

So, things are moving along. In other news, I have decided that the dp1 will carry a one-year warranty. Obviously it is not a proven design yet and I don't expect my customers to assume the risk of any design deficiencies. If it's found to be poorly designed, I will fix it on my dime. Interested in getting one? Let me know! 12/12/06 Recently, John (the creator of the V8) braved the frigid and snowy Chicago-area weather to drive his V8-powered 7 to a dyno and did a few test runs. The engine in that car is the first prototype, a 2.6L unit with 11.1:1 compression. The engine in Bikini is 2.8L with 12.8:1 which will likely be the production spec (subject to further testing). Click on the picture below for a video of the dyno run (you may need to right-click and save as, for some reason when played from the web it stops about halfway - the video is a bit over a minute). The run is done in 4th and tops out at 160mph so there's quite a bit of tire noise. And yes, the white outside the door is SNOW! UPDATE: Got a preliminary dyno chart. Now keep in mind that there is still much tuning to be done so the torque curve still has a couple bumps in it. The figures at the wheels are 306 hp/191 lb-ft so at the crank it's over 360 hp. Quite impressive overall. Based on this, the Bikini motor should be over 400hp. We'll see...

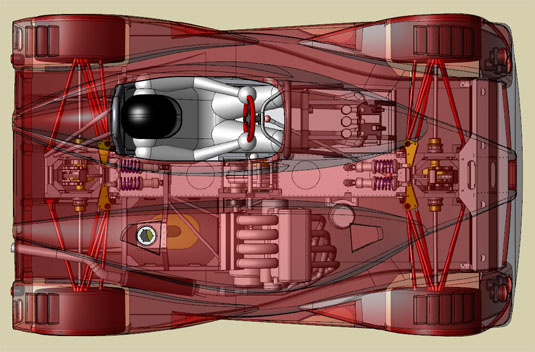

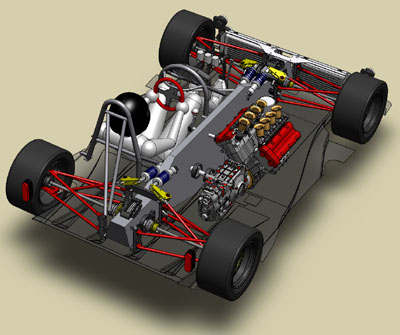

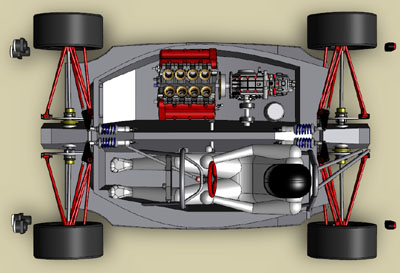

12/24/06 I've been spending quite a bit of time lately juggling all the 3D puzzles involved in the dp1 production chassis. It's still somewhat conceptual at this point but real enough for first CAD. So here it is...

Quite a few details got nailed down in order to have come this far, actually. I now have gearbox CAD from Hewland, the clutch is selected along with its release bearing, the bellhousing design is at least in my head and almost in the computer (naturally, a custom part again). The picture above is of course missing some key pieces but I know what they need to be. There's a certain satisfaction to that. 12/27/06 Some good progress on the chassis. I got the driver model updated for a 6'2" size (thanks to Larry for the dimensions) just to make sure I can fit more people in the production car. The belt drive is now history and it's chains again, although in a different configuration than before. Belts are just too wide, have some installation issues and would require some serious pre-tensioning to avoid skipping teeth (about 2,000 lbs preload). Would have been nice to save 15 lbs but so it goes. With roughly 400 hp I can relax about weight somewhat. From a maintenance standpoint chains are a slam dunk and performace-wise they're proven on 500+ hp drag bikes. Just need to spend some time designing proper guides and tensioners. In this setup the rear chain is relatively short, about the same as on a typical motorcycle. The front one is much longer but carries less load so it can actually be a 520 vs a 530 for a bit of overall weight savings.

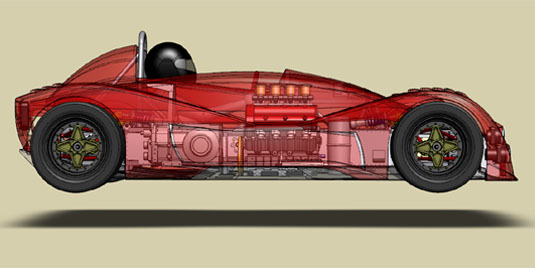

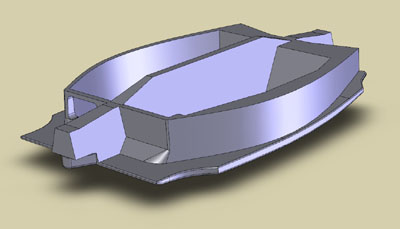

There are some major aero and structural changes based on what I've learned so far. I've downloaded the FIA requirements for composite chassis and am working to ensure my design meets or exceeds the specs. The entire side rail on driver's left will be filled with structural foam for crash protection. Stiffness should be much greater than the prototype. SolidWorks says the new chassis should weigh 52 lbs but that does not account for core material and a few bits and pieces. So figure 100 lbs or so. This compares to about 150 lbs for the equivalent prototype structure (steel/aluminum chassis plus non-stressed aero floor). There will be separate front and rear diffusers and crush structures at both ends. A large single radiator will reside directly in front of the engine, which will make it less likely to get damaged and will simplify plumbing. Notice that the brakes are now four inboard disks. Both current bodywork and a Lotus 340R style open-wheel roadster body will fit the chassis. These will be the standard no-cost options and any number of custom designs are possible at extra cost. Yes, that includes a Classic Mini replica with a passenger seat behind the driver :) Next I need to design the exhaust for the V8 because that will be yet another major packaging challenge which may affect chassis design. Once I have that taken care of (easier said than done!) I can finalize the chassis and hopefully get some aero evaluation done to see how it compares to the prototype. The entire underside is profiled after a Ralt Formula Atlantic tunnel so it'll be interesting to see how that works. 12/28/06 Figured out the preliminary front and rear diffusers, as well as initial radiator placement. Now I need to create a model suitable for CFD and see if I can get a simulation done. Should be quite interesting. Probably quite draggy still but downforce should be a good deal better (click each pic for larger version). A big improvement in manufacturing, repairability and safety too. It's good to be able to do some conceptual and CAD design after all the messing with real-life details on Bikini engine install. But now I'm itching to do something more mechanical and the drysump oil tank showed up so in the next few days there'll probably be another Atom update. |