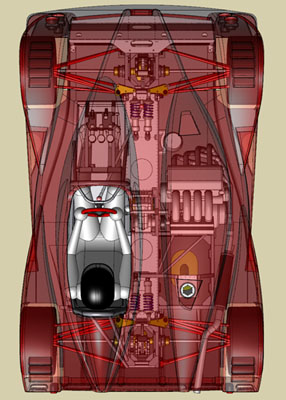

|

10/15/06 Another busy day, spent on bodywork and floor. All along the plan has been to have the whole body tilt up, like a funny car. I think early on I tried that without everything fitted and for some reason it didn't work so I kind of resigned to the possibility that I'll need to do something less elegant. But today, trying to figure out all the possible solutions, I recalled that I had checked the clearances in CAD and in fact had put some effort into designing drafts and features so that it would work. So now that the diffuser mounts are done I rigged up a quick test and sure enough, the body tilts just fine. So I fabricated a couple brackets...

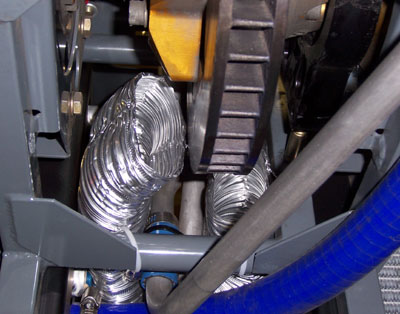

And the rest is history. Whew. Unlike a Radical, you won't need a crew for trackdays :) Now everything else falls into place like it was supposed to, even the exhaust will be easier (tailpipe can stick out farther now that body is not dropping vertically on it). Still a lot of work to be done and I definitely won't make the lunchtime track opening tomorrow but then the weather has been lousy anyway. So Monday I finish the floor and body and Tuesday I hopefully get the exhaust wrapped up. Ambitious but not impossible. Wish me luck! 10/16/06 Progress is slow. Once the floor was off I decided to do something about the brake situation, namely to try and manage the air a little better. A trip to the hardware store yielded some aluminum flexible duct and foil tape. With that, I fabricated proper ducts for the front brake. The tape was also used to seal off the bulkhead between the brake and the rest of the backbone chassis. Dust was getting inside the chassis and into everything, including the front chain. That had to be stopped and I think now it has been. We'll see what impact this has.

All this took quite a while and of course I still don't have the new brake pads (should have been here last week) so the upper dust shield will have to come off. Taking a close look at the brakes reveals considerable wear on the front rotor and a rear rotor that appears to be completely glazed. Neither is particularly good. Well, it was a noble experiment. Perhaps the new pads will help, whenever they arrive. In the meantime I fabricated ducts for the rear brake too. Came out quite neat. I'll take a picture of it with the floor on later.

Speaking of the floor, I went ahead and enarged the mounting holes that needed it and then epoxied a couple barriers to the surface. The purpose of the barriers is to keep any spilled fluids from going under the driver and also to route the front brake exit air to the left side of the car. Hopefully it'll help. Was hoping to mount the floor back on the car today but didn't get it done. More to do tomorrow.

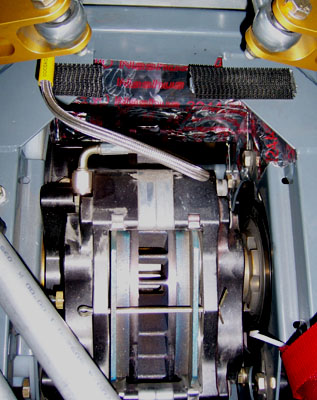

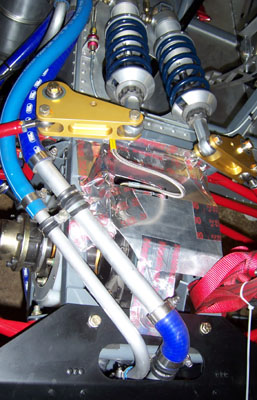

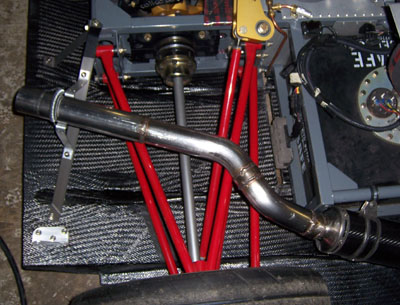

Earlier in the day I designed the exhaust tailpipe in CAD (click for bigger picture). After that I ordered the necesary tubing, it should be showing up tomorrow. The guy who normally does my welding has been out of town and although he was supposed to have been back by now he hasn't returned my calls or emails. This means I'm going to have to attempt to weld the stuff myself. I've only welded a couple of times in my life so this will be interesting. We do have a communal MIG welder, I'll just have to go and get stainless wire, some tri-mix gas and a couple extra wire sleeves. Never a shortage of challenges. It's doable but it'll be close. Will I make it? 10/18/06 The short version: Didn't happen. It rained. Will try again Sunday the 22nd. Now for the long story... As of yesterday morning I still had fnishing the floor, the exhaust, the front body mounts, the brake lights, the mirrors, new brake pads and a few minor items on my list. Totally doable. The pipes for the exhaust showed up at 9:30 am and by then I already had the stainless MIG wire and the replacement liners for the welder. Satya said he'd bring a cylinder of tri-mix gas that's required so all that was left was to just do it. Of course the brake pads still hadn't showed up but UPS tracking said delivery was coming in the afternoon. So off to the shop I went. First item - the gas cylinder is just argon/CO2 mix, not really suited for stainless. No problem, I'll just get the right stuff later in the day. As long as I go before 3 to beat the traffic. The floor went fairly smoothly but did take a while. Just lots of trimming, adjusting, etc. But finally it's on. You can see the rear brake ducts in the diffuser.

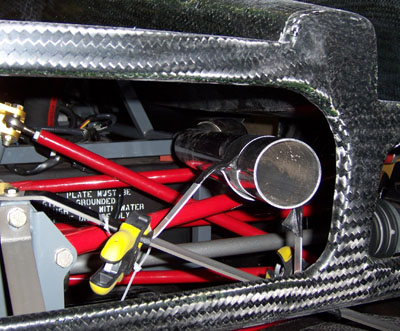

Next up was to cut the prefabbed bends for the exhaust and jig it up before I go get the welding gas. Stainless is a pain to cut but I managed it. Knowing that I seriously lack skill at welding I had designed around the problem. My solution was to get a length of pipe that is next size up from the main tubes so that it slides on top of them with a very close fit. This would serve both to keep everything in place during test-fit and to make sure I'm not doing butt welds. Those are tough and must be executed fairly well to keep them leak-free. My approach, a kind of a bi-directional slip-fit, relies on the 'sleeves' to keep the joint intact and the welding only locates them. This made it fairly irrelevant how good the welds were as long as there's no burn-through. So I cut and fitted the pipes and lo and behold, it fits. Barely. I did decide to move the exhaust tip a bit laterally vs. what I had done in CAD. Just goes to show that sometimes there's no substitute for seeing it in the flesh. I also improvised a quick tailpipe support bracket that I liked enough to make it the permanent solution. Quick, easy and all of about $1.10 in materials for that one (none of the above can be said for the exhaust pipe itself).

At this point it was 3 pm (time flies!) and I headed out to the welding supply shop to get the gas cylinder. Over the phone they told me that the smallest they've got is 80 cu ft and it would cost $173, filled. Not optimal but what can you do. When there, however, I was pleasantly surprised to find they actually have a much smaller cylinder for $60 and they would even refund $50 if I returned it in 30 days. Ok, deal. On the way back to the shop I dropped by the house to find the new brake pads sitting at the door. Sweet. With all the traffic and running around it's 6 pm by the time I get back to the task. Brake pads first, easy. Even the things that I thought were going to be problems (coolant pipe interference upfront) turned out to be a non-issue. So now I have new pads, let's see how they do. It took some time to configure the welder (a portable Miller MIG unit). This is because while I own a portion of it (a third? a quarter? I forget) I've only used it once and just haven't done much welding period. Had to swap wire sleeves and wire, hook up external cylinder, etc. Then I ran some practice beads on scraps I had left over. This is going to be tough. Some fiddling with the settings and then it's time to just do it. First order of business is to tack everything in place using a welding blanket to shield the rest of the car from sparks, etc. This goes easily enough. David drops by to take some pictures and generally bear witness to my endeavors. And to operate the vacuum cleaner switch. Hey, every little bit helps and I was glad for the company. The pix are cool, too.

The result? Eeeehhh... The welds are quite ugly but it'll work. And, it gets wrapped with heatshield anyway. Which I then proceed to do. A few finishing touches and tweaking on the mount and the exhaust is done. Yes, clearance is tight but should work. I can tweak it some more if need be later.

All this consumes a good deal of time. David leaves around 10 pm and I'm left to deal with quite a list yet. I fiddle with body mounts for a while and then when I get sick of sawing, filing and drilling I decide to mount the mirrors. These are from the same Hayabusa that the engine came out of and are a bit big. Also the bodywork at the mounting points is rather thin and the result is that the mirrors are quite likely to vibrate. No worries, it's something I can change later. Will do for now. Now it's 11:30. The side body mounts are done but the fronts still remain, as does hooking up the brake lights. I fabricate the brackets for the front and then at midnight call it a day. I'll be back early in the morning.

Back home at 1 am I give about 10 seconds thought to doing a site update and pass out instead, just having enough energy to set the alarm for 5 am and get all the batteries for the electronics charging. The alarm goes off in the middle of one of the more bizzarre dreams of late and it's a bit surreal to just get myself going on the project again. Throwing all the equipment and gear in a duffle bag I head back to the shop. First, the mounts. It's going slowly. The quarter-turn fasteners I chose are not working too well (brackets are too thick for them) but I can make do. Joe shows up to help at 7am and brings coffee. I continue with the mounts while he gets the tailer hooked up and ready to load. At 7:30 I move on to connecting the brake lights and ask Joe to do the final fitting on the front mounts. It's close. As an instructor I need to be at the track no later than 9:30. It's rush hour outside and the sky is cloudy but it's dry. I'm just getting ready to start getting the car loaded on the trailer when at 8:15 David calls from the track and tells me it's raining there. Suddenly, all the pressure I've been piling on myself the last few days is off. The forecast originally called for rain on Friday, then they moved to Thursday, then possibly this afternoon. Guess what, the rain is here. 20 minutes later it's pouring outside. So I tidy up just a bit, change out of the work clothes and head to the track in the MINI. See the Dark Helmet page for that story. Sunday is another trackday and the forecast is optimistic. I have a few days to make some tweaks and go over things. And get some sleep. Let's see how it goes. 10/21/06 The last couple of days saw some minor tweaks. Fiddled with brake light switch. Resolved the quarter-turn fasteners (I was using Ducati parts that were too short but I remembered that the Triumph ones I had borrowed from David to put the 748 together are slightly longer so I tried those and they work great). Fabricated fake 'headlights' out of cardboard and aluminum tape. Added a couple more floor supports. Fabricated some gurneys for the tail. Tweaked couple edges on bodywork for appearance and to eliminate a rattle. Revised fuel cell vent and added a check valve (it already had a rollover valve but the check valve prevents fumes from escaping). Added some insulation around the exhaust. Put mesh screens behind the front wheels to reduce the amount of flying rocks. Stuff like that.

Pretty much ready to try PIR tomorrow. So far weather looks good. Ball is in my court. |