|

09/24/06 Now that I'm done with the initial design stage and the prototype build stage, time to start another section. This one will be dedicated to the testing and development of the prototype as well as the redesign for production. Much remains to be done - should be fun! :) As a significant step towards the production version I recently took delivery of the first Hayabusa-based V8 motor. Details and specs will come later but for anyone interested the motors will be available from US-based Hartley Enterprises (website still being worked on). Current estimated cost is $28K for the motor including throttle bodies, injectors, dry sump system (minus tank), ECU, starter, flywheel, alternator and an adapter plate for mating to the customer-supplied gearbox. This is roughly half the cost of Radical/Powertec and RST units. As I mentioned details will be released later so please wait for the announcements, I won't be able to answer e-mails.

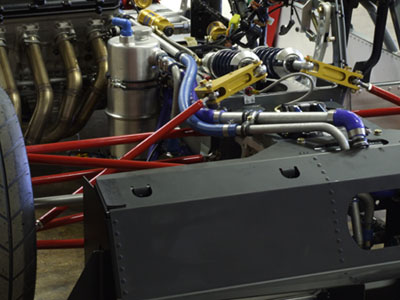

That's about it for now, MUCH more to come! And just to clarify - yes, the prototype is powered by a stock Hayabusa powerplant, including the gearbox. It uses a steel/aluminum frame and chain drive. The production car will be powered by the v8 with a 5-speed sequential transaxle (with reverse), will use a carbon tub and belt drive. So there's no shortage of things to do for the next year :) 09/26/06 Spent pretty much all day working on the car. Lots of little details need to be taken care of. The most time-consuming was plumbing the oil cooler but now it is done.

Next came initial alignment (I decided to start with a conservative 1/16" toe-in at each corner). This went fairly smoothly using a Sears laser level and a tape measure. Other items included fabricating a temporary center sprocket cover plate while the real one is getting lasered, checking and tightening a number of bolts and a general once-over. Tomorrow I'll make plans for the use of a kart track and the goal is to spend Thursday and Friday mornings testing. We'll see how it goes :)

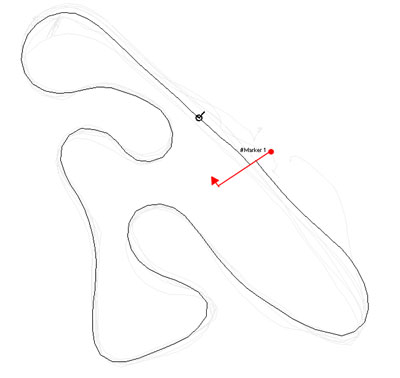

09/28/06 Another big day - the first real performance test. Yesterday I finalized arrangements to use a local kart track, Pat's Acres, for a couple hours before they open for regular business. I've run my shifter kart here before and it's a fun track but TIGHT - so I had some concerns about being able to make some of the turns... I would be using the short version of the track, without the new addition that's blocked off by red lines in the picture.

I made some preparations yesterday but of course today things got challenging even before the day started. The trailer registration is expired and I was going to renew online but turns out I can't do that. Oh well, I'll have to risk it. Also, the trailer had a flat tire so yesterday I pumped it up. Only to find it flat again this morning. Fortunately my friend Joe came out to help and was able to run the tire over to get fixed while I loaded the car onto the trailer supported by a jack. Lots of other frustrating little details but finally I got out to the track only 25 minutes later than intended. Car unloaded, some final checks (Joe is much more procedure-oriented than me, thankfully - I need this kind of influence at this stage!). Then nothing to do but just go for it. First few laps are tentative (yes, I CAN make it around the track even though it's close) - then the pace picks up. Then the throttle jams open. Shut down, fiddle with it, restart, go back to the pits and regroup. Then try again, this time with in-car video (a 28M file). This is FUN!!! Here is some external footage (thanks, Joe!) - a 7M file. This thing gets up and goes. It drives just like a large shifter kart except doesn't beat you up nearly as bad. Which was exactly the intent so on that count I'm 100% successful. The rubber motor mounts work great and there is none of that kidney-tingling vibration that the kart and the Westie have, despite me sitting on bare aluminum. Perfect. After a few laps GPS indicates a best lap of 43.07 seconds which is pretty much identical to what I do here in the shifter kart, except with dp1 I'm running on Hoosier DOT radials and the kart is on soft race slicks. Granted, I'm quite slow by karting standards (best shifter drivers run high to mid-30s here) but with same driver the performance is at least as good as the shifter. And I know I wasn't pushing the dp1 nearly as hard as it can go and was being relatively conservative. There are several more seconds to be had here.

Overall, the GPS shows max cornering of 1.6g, max braking of 1.0g and max acceleration of 0.65g. Top speed on the roughly 500 ft straight is 73 mph. This is taking it easy on the brakes and the gas. Brakes are actually working quite well but of course there's brake dust all over the place. I'll be changing the design for numerous reasons but for the prototype this will be sufficient. Anyway, with the v8 in production my goal of 1.5g in every direction on DOT tires seems doable. The prototype should be able to do it in three directions, I think acceleration will peak at about 0.8g once I can use the engine fully, but the v8 is of course two of these engines at the same overall weight :) The car behaved so well that I felt totally comfortable having both Joe and David take a few laps in it. Neither pushed as hard as I did but their impressions confirmed mine - just like a big shifter kart, no evil tendencies, confident and fast. David ended up taking some pictures with his new D200 - fittingly it was the camera's first field use. First picture is clickable for a larger version, just because it's so symbolic. Not everything was smooth though. After a few dozen laps - a strange noise in right-hand turn. So I back way off and drive to the pits. The noise is only there in tight turns. After some poking around we realize that a suspension bolt had come out! I guess my preflight wasn't thorogh enough! Notice the paint marks are on all the other bolts - but not this one. Lesson to be learned.

Considering how drastic of a failure this is, the fact that the car behaved so well is amazing. Only damage is a couple scratches on the wheel. It really helps to not be taking brake torque on the control arms! This is a major advantage of inboard brakes - the suspension is stressed much less. Anyway, having had a lengthy and overall very successful test session (and with the day heating up) I decided to pack it up after bolting the suspension back together. Feeling quite tired... but happy!

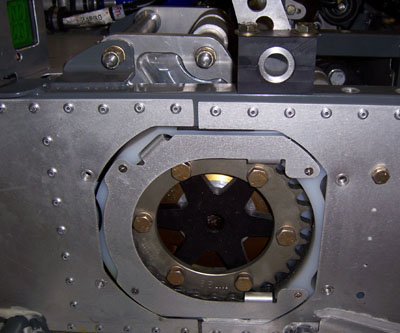

Now, a major going-over of all the mechanicals, an assessment of any wear, quite a few tweaks and such. Then, most likely next week, another test at Pat's Acres. After that - mount the floor, the body and get ready for the big track at PIR. Fun stuff! (By the way - target PIR debut is October 18, Motocorsa/Lotus trackday. Weather permitting of course. They have plenty of spots open, if you want to run at PIR and see the dp1, contact Ray and tell him dp sent you). 10/04/06 A bunch of maintenance and small items. Picked up the lasered sprocket cover and installed it. It's pretty sweet - a fully custom, laser-cut stainless piece for $25 in quantity one. Gotta love technology :)

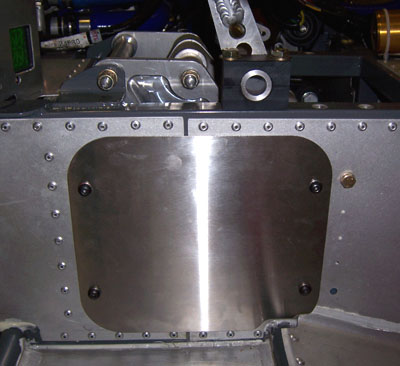

The front brake is making huge amounts of dust. I came up with a temporary cover to try and contain it or at least keep it from blowing back onto shocks and wiring, we'll see if it does any good (no picture of the cover because camera battery died but you can definitely see the dust).

Another item was the installation of a different fuel pressure regulator. The one I was using originally was at the very top of its range at 45psi and I wasn't comfortable that it was working properly like that. Also it had no manifold pressure input. So I got a replacement item and besides looking nicer (and even including a pressure gauge) it has a MAP input and appears to work better. Idle is smoother and doesn't seem to be nearly as nasty emissions-wise. Of course the real test will be on the track.

The reversing box / center diff is spitting oil (just like the Westie did) but it's not too much of a surprise. An interim solution applied at the track and consisting of a shop rag folded several times and stuffed up against the vent seems to have worked. Today I did a proper fix with an external catch canister, hopefully this will do it. New suspension bolts came in and they are the proper length this time. Funny, the BOM shows the right bolts but I never ordered or installed them. I think the short ones were put in temporarily to hold things together and I forgot to replace them with the right ones. Another reminder of the importance of procedures.

The new bolts have drilled heads for safety wire and so I took the time to wire all the critical bolts on the uprights. That's on top of red LocTite. Should stay put now.

The day after the kart track test I discovered some serious bruises on my ribs and legs - just like from the kart. This showed the need for some padding and so I installed that today as well.

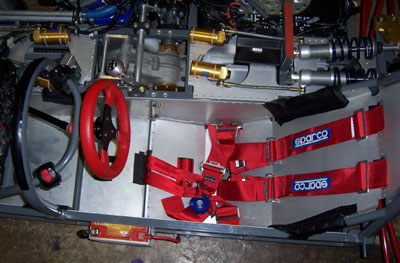

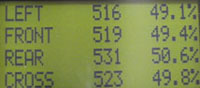

I think I'll still wear the rib vest that I have for karting. The car is now definitely more ready than it has ever been and I'm looking forward to testing it again at Pat's Acres tomorrow morning. Forecast promises partly sunny weather and I hope they're right since it's raining right now. We'll see. On the way back from the track I'm going to stop by a DMV office and see if they will assign a VIN to this beast. If they do, I can then get a title and eventually a license plate. Then I can drive it to the track :) Much remains to be done but there's progress. We'll see how it goes tomorrow. 10/05/06 Second kart track test. It was still raining steady when I woke up at 5:30 am but the forecast called for partly sunny by 8 so all was still go. By 7 the rain stopped and the sun rose above a low cloud layer which dissipated quickly. My track reservation is from 10 to noon. Should be good. I go to the shop and make a few final checks. With an hour to go, might as well put the car up on the scales since much has been added to it since the last time I weighed it. With all the fluids and 5 gallons of gas it's at 866 lbs. A bit more than hoped for but that'll get fixed in the redesign. With me in it the crossweights are just about dead on but the left side is still a couple pounds light - it'll be more even when I add the fire system. Total weight with me onboard is the same as the Westie was without me.

I'm getting the trailer loading down to a routine now. The car is so light I can just push it on by myself. Easy. By 9:45 when I pull away from the shop the sky is cloudless and the pavement is dry, at least here. Works for me. 20 minutes later I unload at the track and get to it. The track is still wet in spots so it's a bit of a challenge. Now that the initial adrenaline rush has subsided I can focus on the car and the driving. The handling is pretty neutral, with mild understeer when pushed but very controllable on the throttle. Just a tiny lift brings the tail out a touch, a precise response to a precise input. Very satisfying. Power can be applied very early and generously. One of the many innovations in the dp1 is the unusual suspension and steering geometry. The design challenge was to come up with something that has good feel and effort, responds instantly, communicates directly and yet does not yank the wheel out of your hands under either braking or acceleration. Happily it appears I've succeeded on all counts. Not bad for a first effort, even if I do say so myself (well, I'm not the only one - read on). Overall I pushed harder than the last time, knocking a bit over a second off the lap time for a best of 41.9 sec. There is plenty more to gain. Peak cornering g is now 1.7 in both directions (not bad for 4 year old R compounds that didn't even get warmed properly), peak acceleration is 0.7g and peak braking 1.2g whenever I can keep it straight. Which brings me to the first limit exceeded and first spin (and another one later). Try stomping on the brakes and the rears lock causing the car to spin instantly - like this short video shows. I've watched it frame by frame and my reaction time is ok but not good enough. When brakes are treated progressively though the car behaves just fine. Smooth is the way. Perhaps I'll play with the bias some. UPDATE: I looked at it carefully again and I had started the turn still under brakes. Second spin was the same way and GPS data shows buildup of lateral G while braking right up to the spin. So just like a shifter kart, the dp1 does not like trailbraking. Kart track is a good place to learn that. Just for amusement, I looked at how long it took from the tail first stepping out to where I had full opposite lock applied. The answer - nine frames or 0.3 sec. And it was too slow. Yep, this thing requires good reflexes! Not a beginner's car but it was never meant to be. And now that I know what to expect of it I have no excuse. Applying power probably would have helped but I don't have myself programmed to do that yet. It'll happen. Having the data and video really helps. How did people do development (or design, for that matter) before technology like this came along? Those guys are true heros in my book. Today also saw the first drive by a potential customer. Page is a great test case - he is an avid car enthusiast, owns one of just about everything you can think of (including Enzo, Carrera GT, Radical SR3 and so on) and he tracks all his toys extensively. He also knows what he's doing behind the wheel. Given all that, his opinion carries a lot of weight with me. I told him to take a couple laps and he just kept going. After over a dozen I had to flag him in because I still had some testing to do. His comments - the car is very fun, easy to steer on the throttle, steering feel is very nice. Basically all the enjoyment of a shifter kart with none of the brutality. He said he just wanted to keep going... We'll see if this translates into an order :) He did manage to break my clutch stop which was actually good - shows the need for a better one. It's one thing to drive the car yourself, quite another to just have someone jump into it and take it on the track. A successful test again, as far as I'm concerned. So now I have my list of things to do in the next two weeks. It's manageable. Barring any unforseen issues or weather problems, 18th will be the big track debut. Looking forward to it :) 10/08/06 Been taking a closer look at the spin video. Here it is at full and then 1/4 speed (4M file) - you can see me start the turn and then a fraction of a second later the tail steps out. My reaction time is about one frame or 1/30th of a second and it takes another 9 frames (about 0.3sec) to apply full opposite lock but it doesn't help. So I started thinking why the spin is so instantaneous. Of course wet track and bumps on the surface are all factors, as are cold tires, but the fundamental issue has to do with the brakes. If you watch closely, I initially turn the wheel but the car just keeps going straight. This is because under braking the Quaife diffs are locked, just like they would be under power, and the car resists turning. Then brake is lifted, diffs unlock and the wheels are already turned... Instaspin. This is basically the nature of development. Early on plenty of people wrote to me about why my brake setup would or wouldn't work. But since nobody has done a front brake like this (there are some rear diff-mounted brake setups out there) everyone was just guessing. As was I. So I went ahead and tested it and now I don't have to guess. It turns out everyone had guessed wrong, myself included. The solution certainly has its appeal - low parts count, low unsprung weight, low stress on suspension components, ease of directing cooling air to the front rotor. Also, it would seem that having some diff lock when braking in a straight line is desireable, it would decrease the chances of locking just one wheel. But it turns out that there is an issue with trailbraking. So the immediate solution is to just drive around the problem - don't trailbrake. I need to program myself to not do that and generally I don't anyway (bikes and shifter karts don't like trailbraking either so I got trained in avoiding it already). Other issues with the current setup are of course brake dust (it goes EVERYWHERE, I even end up tasting it afterwards which can't be good) and the difficulty of removing the rotor for service. So the production version will use a different brake setup although some form of diff braking will probably be retained so I can further experiment with it. Over the winter I might update the prototype with the new setup, that way I can evaluate it on the same chassis as the original one. We'll see. Other experiments have been working much better. As I've already mentioned I'm especially pleased with the suspension and steering geometry I've chosen. It is quite unconventional in a number of ways and of course I've gotten a fair share of emails on that too. Good to be right occasionally :) To sum it up so far: - Brakes will definitely need redesign for production but are workable for the prototype testing and have been quite educational. - Suspension is working well, definitely a keeper. I'll try playing with setup later on but for now I'll just leave it alone since my initial settings appear to be working. - The overall layout of a very short (same length/wheelbase as original Mini) and very wide (same width as a C5 Vette) car seems to be working well also, at least up to 75mph. Of course high-speed testing is yet to be done. The general idea was to get as much mechanical grip as possible and I've been very pleasantly surprised with the results, getting 1.7g peak lateral acceleration from 3-year-old R compounds right out of the box. This is Formula Mazda territory and those use slicks. I'm very curious to see what the dp1 would do on slicks so that's in the plan down the road. Also, looking at the videos there appears to be virtually no roll even at well over 1g cornering so A/R bars probably won't be necessary. The car is so easy to switch between understeer and oversteer with the throttle that I don't think they'll be needed for tuning the balance either. Cost/weight saved. - All wheel drive is already proving its worth by allowing power to be used early in turns, with no ill effects. It does not dull the car in any way which was also an unknown. Another check mark in the 'success' column. - Chain drive has proven to be less of a liability than I feared at least so far (knock on wood!). Major unknown was whether the long chains would stay on the sprockets at high lateral loads. I've taken steps to ensure that they do (constraining them laterally and carrying a bit of pre-tension) and so far it seems to be working. They're also less noisy than I anticipated which is good. Still, production version will use belts. - Visibility forward over the tall front rollbar was a concern but so far it has proven to be a non-issue. We'll see how it goes with bodywork on but I believe it'll still be OK. The next phase of testing, which requires a full track, will have to do with trying out some of my aerodynamic theories with respect to drag, stability, downforce, cooling, etc. Initial impressions will go a long way when I get it out at PIR this month but of course a pretty methodical program will have to be devised. I have three chances on 18th, 22nd and 27th but right now the weather forecast for the 18th is looking gloomy. In the meantime there is a full page to-do list on the wall which needs to get knocked out before the car goes on the big track. It's doable. |