|

07/08/10 In the previous post I had mentioned that the bodywork would get installed Wednesday. It is now Thursday, 6 am, and we're loading the dp1/e into the trailer on the way to Laguna. The floor is suspended from the trailer ceiling but we do plop the bodywork on top of the chassis because we have no room for it anywhere else. Not quite 'installed' but it's 'on'. For the last few days Kyle at RMS has been working long hours designing and machining the mounts for the new motor enclosure that arrived from Remy two days ago. At first, we considered the enclosure swap a nice-to-have option. That was before realizing that the floor won't fit with the old enclosure in place. The bodywork attaches to the floor. And hoses/cables dangle perilously low without it. So about 24 hours ago the swap became a must-do. Checking in last night Kyle put the chances of successful completion at 50%. This morning he is confident that having two days to work on the car at the track he'll get it done. The BMS/charger system that we have been working on is not ready although yesterday mid-day Ken (the EE I"m working with on the system) took delivery of 100 PCBs and populated them enough that they can serve as visual charge indicators for individual cells. He met us at our shop at 5:30 am to hand us the boards before we took off. That still leaves us relying on the borrowed bulk charger which requires 220V input and might be broken anyway but we think not. Also the DC/DC converter that runs the cooling pumps has quit so we're just going to use an Odyssey 12V battery. Should be good enough for the time trial. We load up and drive 14 hours to California. On arrival, all is not well. There has been damage to the suspension in transit and we'll have to repair and reinforce the lower arms. We're also going to need the two spare ones that are currently employed as PC racing simulator steering wheel support. Back at the house in Portland. But the race is not until Sunday so all is not lost. 07/09/10 It's a cold and foggy morning.

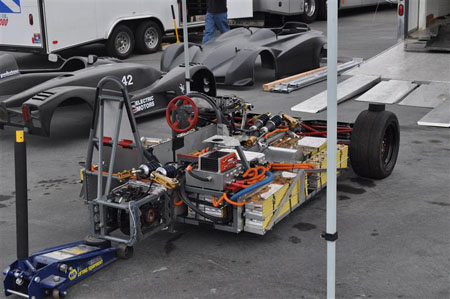

At 7 am, after unloading in the paddock and setting up Kyle so he can do his stuff, we get on the phone with David back home and have him fedex us the arms. Prior to the trip my friend Larry introduced me to Josef, a Salinas-based car guy who runs Competition Tuning, a vintage racecar restoration shop. I call him and he is kind enough to come out and arrange for someone to get our suspension fixed overnight. Hopefully they can get it done. In the meantime, Kyle has plenty to do. The old motor has to come out. The new motor has to be installed in the housing. The mounts have to be attached to the chassis and several parts have to be fabricated, some requiring machine tools. Then the new motor needs to be mounted, chain adjusted, sprocket drilled and aligned and the cooling system has to be rerouted and tested for flow balance. All in a tent in the middle of a parking lot. THEN we can try mounting the floor and the bodywork and just hope the controller and the software do their job. They need to be calibrated to the new motor, of course. Since the BMS is not done yet the battery pack was balanced manually yesterday but it's far from optimally charged. 220V power won't be available till race day so we just don't worry about charging for now.

Throughout the day steady progress is made. Occasionally we take breaks to unwind. Jeremy has brought a bunch of his toys, from motorized skateboards and microbikes to a high-performance RC electric helicopter with which he puts on mind-boggling airshows every now and then. Davide has a natural talent for the little scooters and is drifting them supermotard-style around the lot. He is promptly nicknamed 'Scooterossi' (the name is properly pronounced in the worst fake Italian accent). Additional entertainment is provided when we spot a remotely-controlled motorized recliner chair scooting around the paddock. Kyle can't resist getting a ride.

As daylight fades Kyle is still working with help from Tristan, Davide and Jeremy. The old motor is now out and the mounts for the new one are installed. Tomorrow morning we need to go to Josef's shop to do some machining and it is arranged. Track security kicks us out of the paddock at 10 pm.

07/10/10 Since the dp1/e in its current state is not mobile we had to leave it under a cover overnight. I was concerned about the fog condensation on the 360V pack but all seems well, at least visually. I wipe off accumulated water without getting electricuted and soon work is in full swing. Today M and I actually get to drive while the rest of the crew alternate between dp1/e and chasing sticky throttle issues with the dp4. Josef drops off the repaired and reinforced suspension bits and they go on the car. Kyle gets the machining done.

The new motor is installed, plumbed and wired after a few trips to the hardware store for bolts. Chain tension is adjusted. It is the end of the day and the paddock is deserted. We are finally ready for a test drive.

The wheels go on, the car is lowered onto the ground and all seems well. Kyle drives it a few loops of the paddock and seems pleased. I take a turn and all is well except the power is definitely lacking. We discuss this and it is possible that the new motor has something wrong with it (being a used unit from an electric boat, all we could come up with on short notice). Kyle offers to swap the old one into the new housing but it's getting late. The other possibility is that the controller is not configured properly. To test this we need to talk to it. I try the USB-serial cable on my laptop and it doesn't work. We hook up a wireless Internet connection using Kyle's phone and I go looking for a driver. Someone puts a chair under me while I do that - I didn't even notice I was kneeling in front of a laptop in the middle of a parking lot. Yes, the trailer is only 20 feet away but I'm oblivious to such things when on a mission.

I find a driver for Vista (my computer is Win7-64) and it is still a no-go. There is a Best Buy 25 minutes away that's open until 9 pm. It is 8:31. M and I set out in the Focus and get there just in time. There is an adapter they sell. We test it in the store on a 7/64 platform and it works. Of course the software is on a CD and my computer doesn't have a drive. So I buy a USB memory stick and the store clerk is kind to transfer the programs while I wait. We get back at 9:30 just as security is kicking us out for the night. At least we now have a working serial adapter and a drivable car. 07/11/10 Race day. The time trial is late in the afternoon. I'm still running the dp4 today so part of my time is taken up by that and I'm still slow. Our originally scheduled fast driver had to leave so it's looking like it'll be on me to set a fast lap, which is not good. Fortunately we find a replacement - Jonathan Frost is an instructor here at Skip Barber, knows the track and is not put off by the experimental nature of the dp1/e (he's a longtime reader of the site which helps). Of course we don't yet have a car but we now again have a driver. First thing we attempt is talking to the controller from my laptop which thankfully works. And it's an easy fix, too - the torque limit had been set to half for some reason! Just a few keystrokes and we have power. Next task is to mount the floor.... which doesn't fit. 'Just cut it' I tell Tristan. Which he does and some time later, using the trailer lift to raise the chassis, it is done and the bodywork goes on. Sort of. But good enough. M starts applying decals.

It is now after 1 pm. We have missed the first two sessions and the final one is almost over. Jonathan goes out for the last two laps to at least get a feel for the car. Climbing out he says he knows what it'll take to get the most ouf of it. And he's pleased - it's one of the most fun cars he's driven (this was prior to him driving the dp4!). The race is in an hour and a half. We can now think about charging so we move over to where the charging ports are set up. There are none available. We ask around and finally 'borrow' one. The charger keeps tripping its breaker and can only put in 5A at which rate it will take us 3-4 hours to top up. Eventually we coax it up to 8A. Then someone unplugs us and we don't notice for half an hour trying to answer questions and talk to people. The competitors are called to grid and the pack is still about 40V below where it should be. We stall as much as we can but now we have to go. In the rush I forget to mount the camera and turn on the datalogger. But we're out there. Jonathan completes the lap and we time him at 1:53 (71 mph average speed for this 2.25 mile course) which seems to be good enough for second place based on our stopwatch (click on each picture below for larger version). Then he doesn't come in. Turns out he ran out of battery four turns after the end of the lap and the controller keeps going into shutdown mode. We go out to turn 5 where he is parked and after pushing the car up the hill (good thing it only weighs 1,100 lbs) we get him back to the pits. Our day is done and we slowly pack up while waiting for the awards ceremony. The awards part is a bit of a surprise when they initially announce us in 4th place. Then, after vague reference to double transponders under fake name which is never explained, we are awarded third. Seems the Wrightspeed car was allowed a rerun after a spin and beat us by a second. Still, given the circumstances being third out of 20 entries is not bad and beating all of the Teslas is an added bonus. Congratulations to the entire team - to say that everyone did an outstanding job is an understatement.

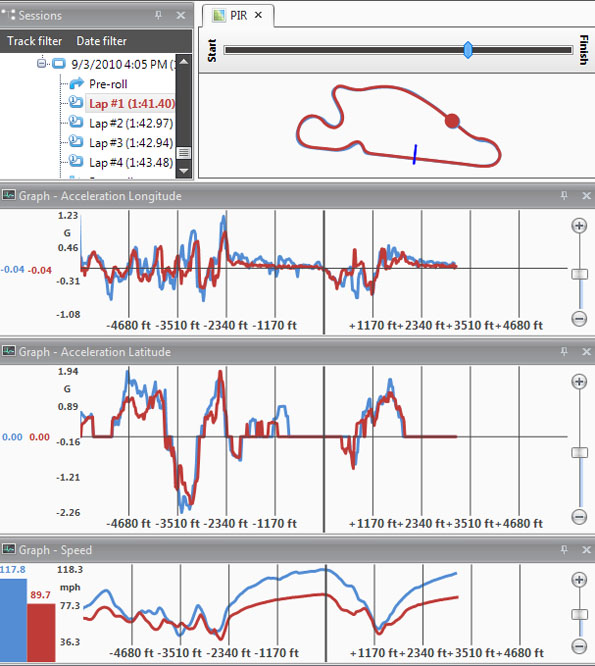

Of course the real value in this trip is everything we've learned. And one of the things we've learned is that we can overcome quite a lot when we don't give up. There is much work ahead of course but this is a very encouraging start. It'll be interesting to see what we'll be able to do with some development and testing. 08/10/10 Testing and development continue on the dp1/e although I haven't been posting about the specific events. They've gotten pretty routine now. I did make a video of a session at Pat's Acres. We still need to do more (and better instrumented) testing but so far the results are encouraging. At a recent endurance test the car went for over 1.5 hours on a charge, with top speed of 65mph and average of 35mph, covering about 45 miles at a pretty good pace (see video above). We stopped when the Odyssey battery that's running the cooling pumps died. The main pack was still going strong. As I've mentioned earlier, even though we're doing the testing on a race car the components and technologies we're developing are mostly intended for commuters, city cars and the like. So the car's performance should be taken in that context. When we do finally have products to offer for sale based on all of this you can expect some pretty fun little city runabouts :) But all that is many months away still. 09/03/2010 Finally got a chance to do some high speed testing at PIR. Since we don't yet have a portable way of recharging the car it meant only doing one session but even that is quite valuable data. So after all day running the dp4 late in the afternoon I finally jumped into the dp1/e for a 15-minute outing. Here's a video from that run. Best lap was 1:41 driving pretty conservatively and average was 1:42. Looking at the data and comparing it with the dp4 it's clear that most of the difference is in the top speed which is around 90 mph for this car in current configuration. Having only one gear is a drawback and some of our future development is aimed at addressing this. Of course the fact that we can't draw much power from the batteries is a hindrance also, I'm guessing we are limited to about 55-60 hp right now.

Of course the dp4 is running way below its max power also, but the speed difference is dramatic. The graph also shows that I could have carried more speed through 10-11 in the dp1/e :) I've a ways to go as a test driver still. Lately when in the car I spend too much time being an engineer whereas I should be 110% driver and leave the engineering for when I'm not on the track.

All this experience is proving quite valuable and we have very ambitious goals for the project. Our big goal next year is to compete at the Pikes Peak hillclimb, both with electric and gas powered cars. So we are now actively looking for sponsors to help make that happen. 10/03/10 After changing gearing and some controller parameters, it's time for another test. This time the gearing is taller and the controller can draw more power from the batteries. We saved the dp1/e test for the end of the day (worked out well since dp4 broke its chain just before that so we didin't really lose any time). The car accelerates slower now and top speed is only a few mph faster so the gearing change is not an improvement. We did draw a lot more power - so much so that we overheated one battery cell to the point of outgassing but not before getting a half-dozen full speed laps in which isn't too bad. I was on the back straight motoring along at just short of 100 mph when I smelled a sharp odor and saw a whiff of smoke. Time to slow down and pull off! All the way into the pits I kept watching for signs of anything worse developing but things stayed pretty constant so I kept going until I parked at the trailer. Getting out and lifting the body revealed that one cell was bulging out and spewing foul-smelling mist. No fire though and the car is still drivable. So we let it cool down and the battery returned to its normal shape after a while. Now we need to go through the logged data and see what more can be learned from all this. We need to get our BMS working soon, it is essential in further progress. The tradeoff when using this battery technology (LiFePO4) is current capacity vs weight and volume. The total energy storage appears adequate for many tasks and the cost is very good. The problem is that a 320V pack using 40Ah cells weighs 400 lbs, which is reasonable, but you can only pull about 120A from it continuously, just short of 40KW. If you go with 100Ah cells it's possible to pull 300A (96KW) but then a 320V pack weighs over 800 lbs and takes up a LOT of space. Using fewer cells reduces pack voltage and therefore available power, it also reduces the speed to which motor can carry full torque. So it is quite a challenge to design a system that fits within the various boundaries of the power/weight/size/cost/capacity envelope and still produces useful performance. Lots of people in the EV industry are fond of quoting staggering peak numbers and they just gloss over the fact that if you actually try to use the car in that manner for anything but a single 1/4 mile run, something will overheat and either break or at best require a lengthy cooling-off period. That's why we're doing this project, to find out what the reality is and learn how to make something that actually works. The best lap was 1:40, a one second improvement on the previous effort. Video shows some highlights. You can see the advantage in cornering and disadvantage in top speed vs regular cars. I did soundly beat the Taurus SHO and could kind-of hang with a GT3 Porsche for most of a lap. If you watch in HD you can see I close the gap on him a bit in the end through the esses... And then he gets on the back straight.

|