|

01/18/09 This entry starts the log for the electric version of the dp1 prototype. Not a whole lot to report as of yet, but be sure to read the '?' page for a lot of background information and answers to some common questions. More to come.

01/25/09 Unsurprisingly, the dp1/e announcement has resulted in a lot of emails, with both questions and suggestions. Almost invariably the subject of one or another company claiming such-and-such comes up. So I think a representative analysis would be useful to include here - it turned out a bit lengthy but I hope you can take the time to read the whole thing :) The lucky subject of this discussion is Hi-Pa Drive and since their site discloses they are in Administration (i.e. Bankruptcy), one might wonder how a company claiming possession of 'game-changing' technology and revolutionary product could end up this way, in this day of green = gold. I have nothing against them personally, not any more than I would against any other hypester giving the industry a bad name, but this was one of the links sent to me and so I figure it's fair game. Let's start with their motto, right there on the front page - "Removing oil, carbon and cost from vehicle propulsion without compromise". Hmm... Many an engineer would stop reading right here, as the reality is that engineering is ALL about compromise. The rest of their opening paragraph is there to read so I won't bother quoting it. Moving on to the claims for their F150 electic prototype - built "to demonstrate that automobile manufacturers can create vehicles that are powerful, clean, economical – and still profitable". This is convenient because I just bought a brand-new F150, with a 202hp V6, for $9,950 out the door (granted it was half off MSRP but it was purchased at retail from a dealer with end-of-year factory incentives and anyone else could have done the same - I suspect it is at or slighly below what it cost Ford to make it). The truck gets around 12-18 mpg when driven moderately and with its 202hp seems to top out at around 95 mph with a tailwind, or at least I haven't found a place to make it go faster. Now on to the NO-COMPROMISE green version. - "Four Hi-Pa Drive motors each weighing 66 pounds, so unsprung weight is not an issue.". (We'll just have to take it on faith that adding 66 lb of unsprung weight per wheel is not an issue, and nor is subjecting the motors to the vibration, moisture and dirt inside the wheel - picture driving through a puddle with several hundred volts going to the wheels). - "A propulsion system that replaces the engine transmission, drive shaft, differentials, axles, exhaust system and supporting subsystems" (with four motors, four high-power controllers, lots of high-current wiring, contactors, battery management system, battery, charger, etc.). - "A configuration that leaves room for a powerful 40 kilowatt hour battery that fits inside the existing chassis– plus more space for passenger and cargo" (40 KWh of energy is contained in approximately 1.1 gallons of gas - more on battery size, weight and cost later). - "The flexibility to control each wheel independently, or all together – the truest form of all wheel drive." (OK, no argument there, though there's more to it than one might think). If you are now excited to learn more, perhaps it's time

for the press

release. There we learn that "The Hi-Pa F150 truck is powered

by four Hi-Pa Drive™ in-wheel motors that will be able to First, the onboard energy capacity - 40KWh. It means exactly that, drawing 40KW of power it will last an hour. Drawing 80KW it'll last half an hour, and so forth. Now power from the battery doesn't just end up in the motor, it has to go through wiring and controller(s). The efficiency of such systems, under ideal conditions, is 95% (80% is more typical as an average over normal driving conditions but let's say it's 95%). So we have 38KWh available to drive the motors. The claimed total power is "over 600hp" which is 447KW. So at full power, the energy in the battery would last 38 / 447 = 0.085 hours or 5.1 minutes. To travel the claimed 100 miles in that time the F150 would have to go 1176 mph. Even with 600 hp that's a bit of a stretch for a fullsize pickup :). 130 mph is more realistic which in 5 minutes would cover 11 miles before running out of juice. OK, you say, the truck wouldn't really use 600 hp all the time - fair enough. I probably use on the average quarter to half of the available power in my truck to get around, so let's call it 50 hp averaged over normal conditions, with average speed over entire trip of about 45 mph. Keep in mind it's a 6,000 lb vehicle with the aerodynamics of a barn so this assumes quite leisurely progress, which is indeed how I drive my F150. So that's 37KW sustained average (not making much use of that "over 600hp"). Therefore the duration is 38/37 = 1 hour. To go the claimed 100 miles under this conservative driving approach would require trip average speed of 100 mph. Hmmm... Not likely in a full size pickup using 50 hp, it takes about four times that. Taking our trip speed of 45 mph this gets us, predictably, 45 miles down the road. Not entirely useless, although "game-changing" doesn't exactly spring to mind. Maybe if it were a lot cheaper or more convenient...? Let's look at the battery. The cost data I'll use comes from Everspring site, and while they're obviously trying to sell a particular kind of battery it corresponds reasonably to what I've seen (the numbers are on the low side if anything) so as a ballpark it'll do. Their battery is rumored to be at $0.50/Wh so let's just believe Internet lore and call it that. Energy density came from Wikipedia and I took the upper number if a range is provided, just for added optimism. This gives us the following:

I can tell you from experience that the above is very optimistic for Lead Acid, and 40KWh in any form suitable for vehicle use would weigh well over 3,000 lbs and cost closer to $10,000 but maybe I just haven't been sourcing things right which is quite possible. Anyway, let's look at the bottom line. The cheapest, Lead Acid, has a lifespan of about 400 cycles. Taking our previously estimated 45 mile real-life range and rounding it up to an even 50 miles, that's 20,000 mile life for the pack. At $6,400 it works out to $0.32/mile battery cost. During this time the vehicle will consume 16,000KWh of energy which at say $0.05/KWh would cost $800 or an additional $0.04/mile for a total consumables cost of $0.36/mile. This of course is neglecting the fact that it's now a roughly 9,000 lbs (empty weight) vehicle. But the cheap Chinese LiFePo4 cells are the real game-changers in the EV industry, right? At 1,100 claimed cycles and same 50 mile range that's 55,000 miles. If the rumored pricing is true that's $0.36/mile plus the same $0.04/mile for electricity or $0.40/mile total consumables cost. Not bad actually, since it's the same cost/mile as Lead Acid at 1/3 the weight. By comparison let's assume the recent $4/gal gas price will come back and become the norm and let's say 12 mpg for the gas engine, resulting in $0.33/mile. At current US gas prices it's about half that. Not too far off, all said and done, but again "game-changing and without compromise" is not how I'd describe it. And that's before considering refills... Since you only can go about 50 miles per charge, you'll be recharging often. At 12 mpg the gas-powered F150 would go about 300 miles and it takes maybe 5 minutes to refill it, including payment. If you recharge a car at home from a 20A, 120V socket (roughly 2.4KW of power), dumping 40KWh of energy into the battery will take about 17 hours and that's before accounting for losses in the charger and the battery (add another 4 hours or so in real life). So you go 50 miles, wait a full day and repeat. Attractive. Granted, going to 220V power brings the charge times into overnight range and makes it a somewhat usable solution. And the cost? Consider that a 20hp peak / 6hp continuous golf cart motor costs around $2K and a controller to run it costs that much again. Now take a guess at what a 150hp motor and controller would cost. Then multiply by four. Then add the truck. So you're looking at something like a $75-100K vehicle (not including battery) which does less and costs as much or more to run as the standard F150. The same F150 that Ford is having to sell for under $10K to clear it off the lot. Alright, enough numbers and calculations - suffice it to say there are plenty of other factors to consider (like where the electricity comes from). The point is that there is no magic bullet and when some new startup comes out claiming they've solved all the problems, the press cheerfully picks it up and some investors greedy for dotcom era returns or just "feeling green" pile a bunch of cash on them, the result I think is a disservice to all of us. Electric cars CAN be useful and affordable, even with today's technology. But we must change our expectations and change how we use them. Consider that most trips are single-person and only a couple miles in duration. Building a 9,000 lb 600hp electric behemoth for this task is just more of the same insanity that got us into the current predicament in the first place (especially considering it takes a lot more energy to build such a car than it will use in its lifetime).. Or a $150K 'replacement' for a $60K sportscar which weighs 50% more and goes 1/3 as far, 1/10th as often? Nah, but thanks anyway. Build the car for the task it can do well and use it accordingly, and yes keep your regular car(s) for trips the electric can't do, or better yet just don't take those trips at all. I firmly believe that the whole gas-car-driven suburbia 'dream' is actually a nightmare and we MUST redefine how communities are built and how we live within them. The electric car can be a catalyst and an enabler for this, even in its currently limited form. As an example there have been communities successfully built around the lowly golf cart so it's not just idle talk, it's beginning to happen. As far as full-function cars go, improving their efficiency and reducing pollution by various means is still the most effective course to pursue and will remain so for a while. Just swapping to electric power without dramatically changing what the car is expected to do and how it does it won't work. So with all of the above, one might rightly ask what am I doing with electrifying the dp1? The answer is simple - as I stated on the '?' page of this log, technologies necessary to make electrics suitable to more tasks and give them broader appeal must be developed and tested. It's an incremental and ongoing process, we have to start with what we've got and push forward. Proper and meaningful testing requires a controlled environment and repeatability. Not having my own test grounds, this means a racetrack - whether go-kart sized or full sized. And the car I use as a test platform needs to be suited to that environment. Yes, I've done a handful of laps of PIR in much lesser electric machinery but at 3:09 a lap you can't be on the track with other cars. And yes, I do have an interest in being involved in EV and hybrid racing. Development of some EV technologies requires focused application of a lot of money without wasting it. Normally that's very hard to achieve but big-time racing with its huge budgets and intense competition is a good way to do exactly that. While some may sneer at KERS in F1 as greenwashing, I personally think it's a great means of moving technology forward and I'm privileged to have had a glimpse of actual progress being made. These guys are not shy about spending what it takes to get an advantage but they won't chase vaporware. We can leverage some of that development to trickle-down technology through the racing ranks to club level and then someday to the cars the average consumer might drive on the street. I think the next few years will be interesting indeed for the EV industry. Real solutions will get sorted from hype, just like some real and lasting value has emerged from the dotcom craze and changed our lives as a result. I hope it's sooner rather than later and I'm intent on doing my part. 04/07/09 With everything else going on the dp1e has been a bit lower priority. But that doesn't mean that nothing is happening. The motor is here, the batteries are here, bunches of parts are on the way or in progress.

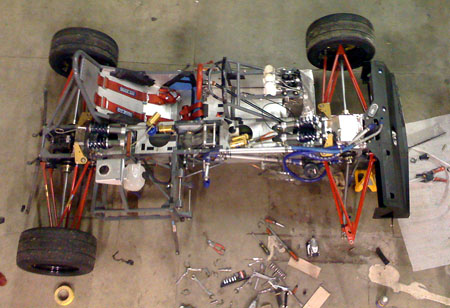

It'll be a while yet before it runs but we're moving ahead. Stay tuned. 04/17/09 One of the things we've been working on for this chassis is replacing the uprights. After the threaded insert failed on the track the last time the proto was out, I don't want to take any more chances with it. So the new design (call it version 1.5 since production dp1 design is evolved further from this) has been fabricated and now installed - Karl did a good deal of the work with help from Tristan. Turns out this design is fairly hard to install and it's been fixed in the production version.

In other news, the arrival of the dp4 test body puts this one into perspective.

There is definitely family resemblance (from some angles more than others) but I'm also glad I'm moving forward as a designer. Now that the chassis is sitting on its four wheels again the next thing is getting the electricals integrated. This will take some doing bit it'll be worth it in the long run. 06/09/09 While the dp1/e is not the highest priority among all of our projects, from time to time we are still able to make progress on it. The batteries are now mounted (as I've mentioned they'll be replaced by a higher performance pack later but the lead-acids will do for initial testing).

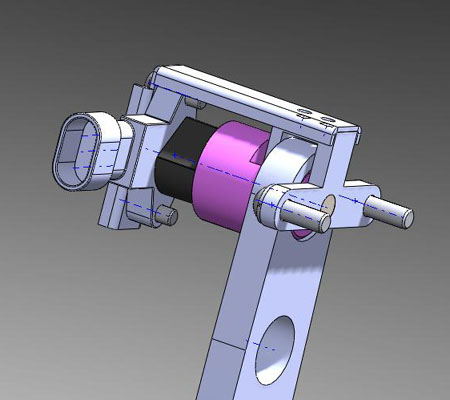

After we mount the motor the chassis will go over to Rinehart Motion Systems who will install their controller and carry out the initial testing. I'm rather looking forward to driving this chassis in electric form. Should be fun. 07/07/09 Work continues on the dp1e, both here and at RMS. Kyle has provided a few pictures of the brake transducer (to drive the regen), the new dash and the CAD of the 'throttle' pedal transducer, the latter being a sealed non-contact potentiometer - pretty neat stuff.

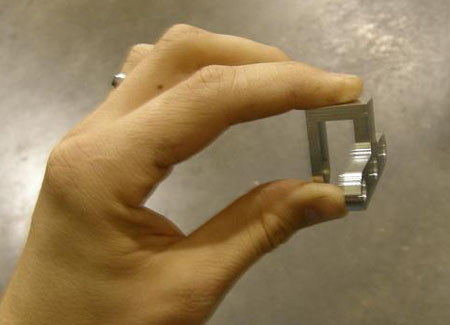

The dash is an integrated display/datalogger from XTRacing. I haven't seen this one before and I like it a lot. After using the DL1 for years (nice unit but software hasn't been updated in literally 3 years) and occasionally looking at Traqmate (similar stuff but much more current software and somewhat better pricing), I've occasionally thought about designing my own logger. Would have by now, if I didn't have all this car stuff going on. One thing I would definitely want is a 3-axis accelerometer instead of the 2-axis ones that are in other units. It's required to make the thing useful on bikes and it's handy in cars too. Lo and behold, this little box has one. And it integrates a display in a nice and compact unit costing under $700. You'd spend 50-80% more and end up with two boxes if you want a display with the previous-generation competitors. Might just have to get one myself. Our target for first electric drive of this car is in a coule weeks. Quite a bit still to be done but it's getting there. 07/20/09 (updated 7/21) Almost there :) The first all-electric drive of the dp1 is only a day or two away. Quite a bit of work took place at RMS to get it ready - besides the wiring (and of course making the controller) quite a few parts and fittings had to be made. Kyle took these pictures of the accelerator pedal bracket that he fabricated - the billet, the part and the installation.

We looked at doing a removable adapter for the output of the Ford motor, and will probably do one eventually, but for now it's just a flange welded to the shaft.

The car is looking pretty complete, with the RMS controller sitting on top of the battery pack - where the fuel cell used to be in the gas powered version.

More updates soon! :) UPDATE: Yes, the car did drive under its own electric power for the first time. I'll have pictures and video shortly.

|

||||||||||||||||||||||||||||||||||||