|

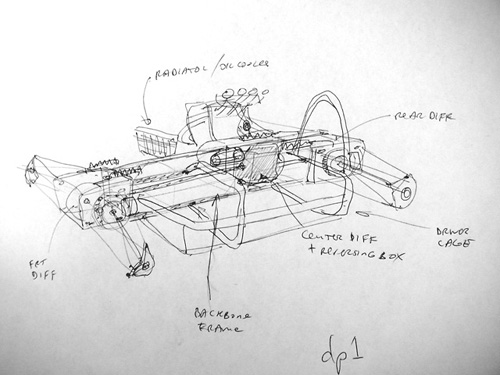

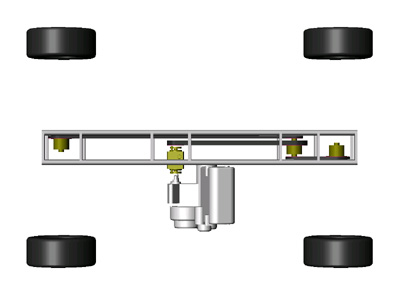

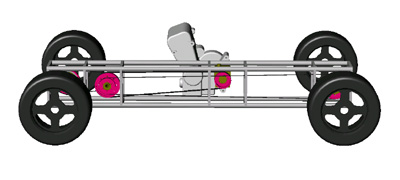

05/26/02 After much deliberation finally decided to start the project. I've always wanted to do my own car, but it was just a vague idea without much focus. Recently I completed a Westfield Megabusa kit and drove it on the track for the first time. I absolutely love the engine and gearbox, which came from a Suzuki Hayabusa bike. The Westfield weighs in at almost exactly 1,000 lbs and is an absolute blast to drive. It's almost as much fun as my recently acquired shifter kart. These two vehicles have made my Elise S190 seem luxurious and large... But of course too much is never enough, and I got the desire to take it further. To combine the best attributes of all my fun machines, and take it up a notch. Or two. It quickly became clear that I had to do my own car. It would be powered by a Hayabusa engine, of course, and use its 6-speed sequential gearbox. And it had to be smaller and lighter than the Westfield, while retaining the ability to be driven on the street on occasion. I've looked around and done some comparisons, and realized that a target weight of 700 lbs should be within reach if I make it a single-seater (at low weights, passengers really cut into the fun anyway). There are several turbo kits out there that take the motor to well over 300hp. That much power in a 700 lb car would make all-wheel-drive an absolute necessity. As such things often go, at some point I suddenly and clearly visualized what the layout would look like: a scaled-up version of a shifter kart with engine beside the driver and a driveshaft running forward and back in a central backbone chassis.

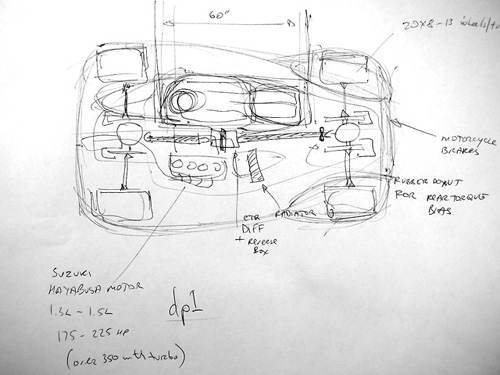

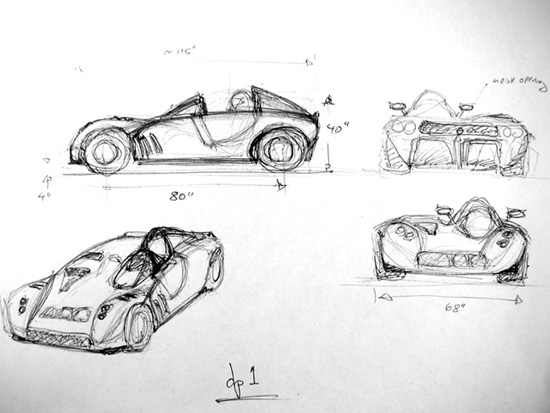

The dimensions came in at 80" wheelbase, 68" width, 115" length, and 40" height (about 30" height for most of the body), using 13" wheels with 225/45-13 R compound tires or 20x9 race slicks. Ride height is 4", which I have found out works OK on the street (the Westfield is 3.75" in the front, and both the Elise and MCoupe are about 4" off the ground). The overall design concept quickly evolved from that...

05/28/02 Coincidentally, I had recently discovered that Lee Stohr, an engineer here in Portland, has been designing and building DSR and Formula Ford cars from scratch for quite some time. And having much success with it, too. The DSR car is particularly appealing (pictures from Stohr site):

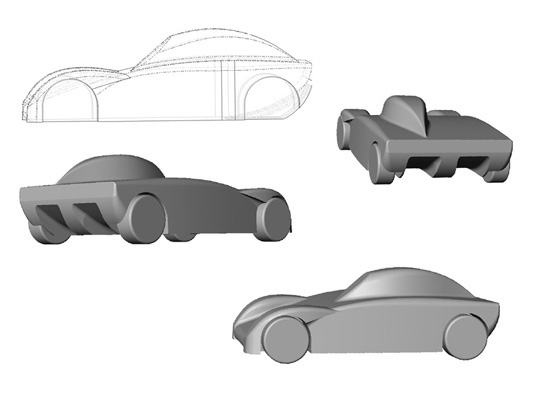

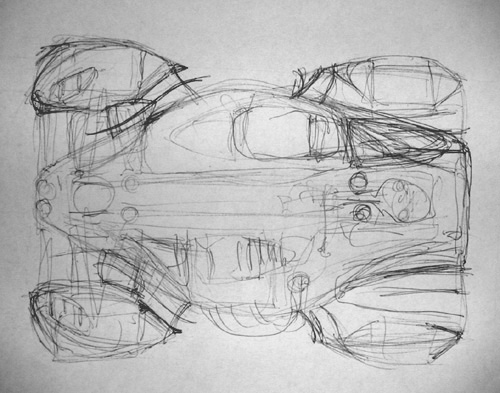

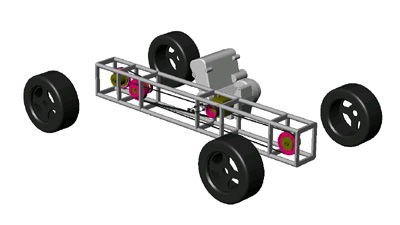

My car would be very similar in construction. A few conversations with Lee confirmed that the project is doable and he would be willing to undertake the construction and some of the chassis design (as well as small-volume manufacturing, if it ever came to that). So it is now official! The goal is to have the chassis and drivetrain complete by December, and have the car finished in May 2003. 05/29/02 Did some quick CAD in Solidworks to check dimensions and proportions. Nothing too elaborate (I'd have to really work with the surfaces to get it right), but another confirmation that this thing would work :)

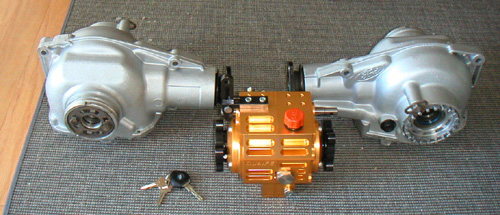

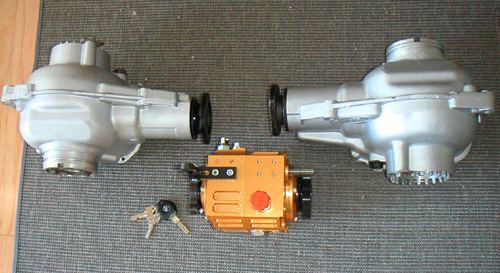

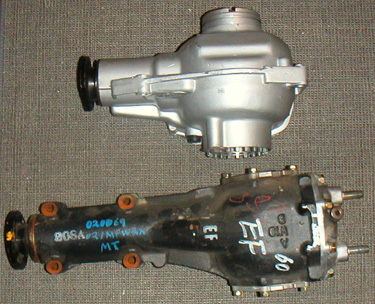

Cool. 06/20/02 I have finalized the choices for front, rear and center differentials and the reversing box. Found a source in England for all the above, and placed an order today. One thing I realized is that the differentials dictate a right-hand-drive setup unless I want to invert both of them. RHD may actually be an attractive option, since it is the preferred layout for race cars, and if I were to ever start selling these the primary markets would probably be Japan and England.... Not a final decision yet, but looking like RHD as of right now. A preliminary spreadsheet of components shows that weight should be close to target, and cost similar to the Elise. It's moving forward :) 7/11/02 The first of the drivetrain parts arrived from England - a reversing box and two differentials (the center differential is still back-ordered).

The reversing box weighs 18 lbs according to my scale, and the diffs 30 lbs each. A bit of a mystery is that the total shipping weight DHL had for the package is 49 lbs. I did a quick check of the scale and it seems reasonably accurate. Hmmm... Now that I see the diffs in person I'm not convinced that I want to use them. They were selected on a recommendation but perhaps I should continue looking. Perhaps I'll start out using them and then switch to something different later. These are definitely the lightest diffs I've seen so far by at least 20 lbs, but that doesn't mean I can't find something better. A good starting point I guess. 7/12/02 As I am always thinking about the project, was sitting around and going through some concept refinements in my head. A couple turned out worth sketching:

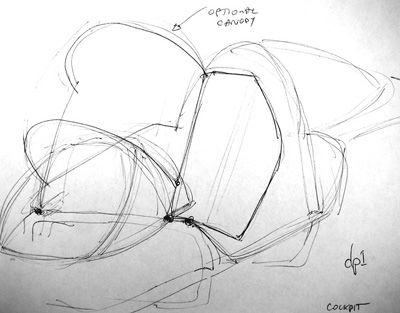

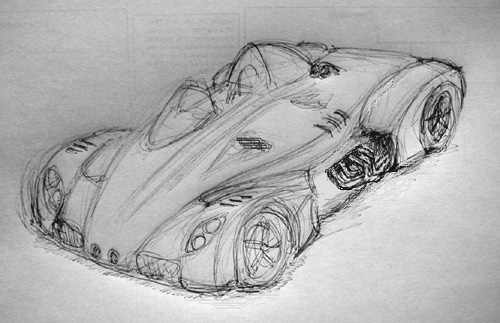

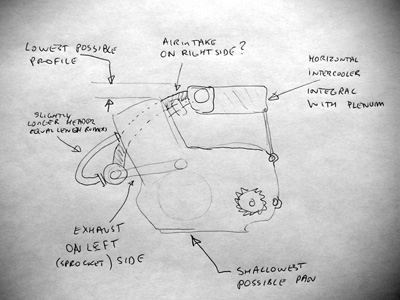

The aerodynamics now include diffusers under the nose as well as the back, changing one big radiator to two smaller ones and moving them into the nose with top exit vents, and better airflow management. From air's point of view this becomes a formula car with with wheels faired in like those on a light airplane. And a bunch of downforce-generating venturis. I also narrowed the bodywork in the middle wrapping it tighter around the driver and motor, which allowed the elimination of a door. The exhaust now pokes out the side and then ducks back into the bodywork where it either goes directly to the muffler in NA version or gets a turbo bolted to it in forced induction version (the exhaust header is the same for both). In FI mode the intercooler sits horizontally above the engine, gets fed air from below through a scoop and is vented to the low-pressure area above. NA version uses the scoop for ram air to the airbox that replaces the intercooler. Or that's the plan anyway. 07/18/02 Acquired a different differential, this one from Subaru WRX. It is quite a bit narrower than the Ford one, and more compact. It is also a limited slip, much more readily available and is $350 vs $500. Of course one big downside - it is 19 lbs heavier at 49 lb. This is because the case is cast iron vs aluminum. It should prove a lot more durable, and considering that I'm contemplating up to 350hp in this device, the extra toughness would be quite welcome. But... Given that there are two of them, that's 40 lbs of extra weight. On a car with a target weight of 700 lb that makes a huge difference. What to do, what to do...

This component selection by trial and error could get rather expensive. If I had a catalog of components with all pertinent data it would be so much easier. Well, if it were easy a lot more people would be doing this, I suppose. Onward. 8/01/02 Been thinking about the engine details a bit. Got in touch with a couple vendors of turbo kits, and made a sketch to send out to tell them what I'm looking to do:

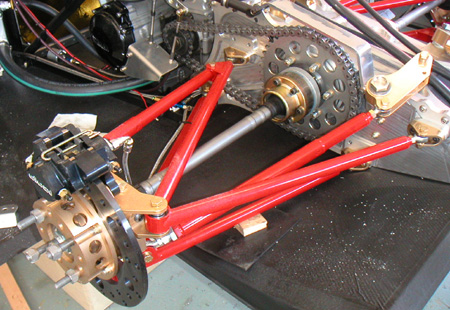

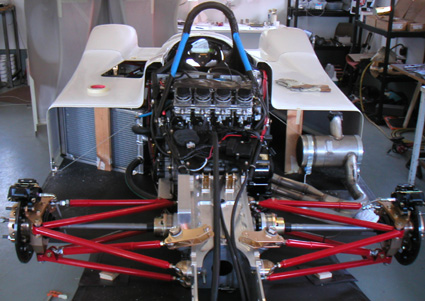

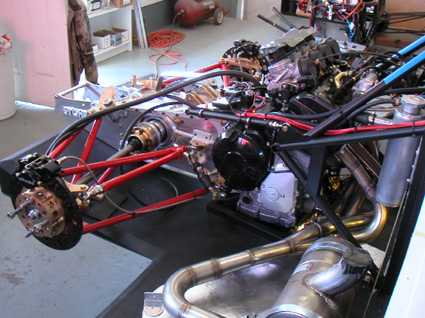

The general concensus is that 300 hp is not a problem, even on pump gas. Taller 5th and 6th gear is also a common modification, as is reinforced clutch. So in all I'm not trying to do anything too far out of the ordinary. If I recall correctly, my favorite car in college, the Renault R5 Turbo, had a 1.2 liter engine (vs 1.3 for the Hayabusa), and came stock with 180 hp, optional 225 hp tune and some versions up to 400 hp. All that using 1985 technology... So yes, this should be not only doable but reliable. Waiting for quotes now. I'm still struggling with the choice of differentials. Took apart one of the 'WRX' units only to find that instead of the limited-slip WRX diff it is an open diff from a standard Impreza. Dimensionally they are great, but the weight is a real issue. An extra 40 lbs in this car is a 5% weight penalty. Plus I suspect the weight is going to be an issue with some other components as well. The driveline is proving to be a real challenge. In addition to the diffs the choice of drive from reversing box to center diff and couplings between all the pieces is still up in the air. Yes, of course there are easier ways to do this - but that isn't the point :) 8/07/02 Paid a quick visit to Lee Stohr's workshop, to see how his latest DSR construction is going. The car is very impressive (hope one day someone will say that about mine ;)

It's great to have people like Lee here locally. He's been through the component selection, the design, subcontracting, development... And he's living proof that it CAN be done. Cool. 08/20/02 Going through a great debate - the source of the engine. Based on my experience with the Westie, I've decided that I definitely want a brand-new motor for the dp1. It would also be a requirement if I were to start selling them. Soo... The Hayabusa motors cannot be bought from a dealer. I can get ZX12R motors, which are equivalent, but the basic block costs $5K and I then have to spend another $3K on parts to make it run - downgrading the ignition coils and having to mess with custom ECU maps in the process. Another problem is that the source which I found in England for Hayabusa dry sumps doesn't have a ZX12 one. The people who supply the Kawi motors are working on one, to be available early next year at a price that's likely to be $1K more than the English 'Busa system. Also, I think I want to use the dashboard, turn signal blinkers, windshield and maybe a few other items from a bike. Therefore it's looking like I'm going to buy a brand-new Hayabusa and take it apart, then sell the parts I don't need on e-bay. Found a source for $10.2K out the door (great to have no sales tax here in Oregon). It's 95% decided. I'll keep thinking it over for the next two days... In other news, I've all but given up the search for proper shaft-driven differentials, and decided to go with belt drive instead. It will be more efficient (96% vs 94% for the shafts) and about 60 lbs lighter, at a similar overall cost. I'm making some headway on other driveline components, like CV joints, halfshafts, flanges and brakes. Waiting for a first-cut suspension geometry design from Stohr. The final component choices will dictate chassis design. This is quite a project.... 08/22/02 The engine debate is over. I've ordered a brand-new 2002 Suzuki Hayabusa, due to arrive in a week or so. I'll probably ride it for a month or so as I've always secretly wanted one but was aftraid it would be too much (the thing does almost 200mph, 9.6s in the quarter mile and will power wheelie in the first three gears - bone stock, right off the showroom floor). No, I won't be exploring anything near its full potential. I'm man enough to admit I'm nowhere near man enough for the job ;) Now put that motor on 4 driven wheels at similar weight, and it might be a different story... 08/31/02 Picked up the Hayabusa.

It's a BIG bike when just maneuvering it around before getting underway. Once moving it 'shrinks', somehow becoming compact and agile. And of course the thrust available is amazing. Even only using half-throttle and keeping it below 5K RPM. It just flies. But it also reminded me why I don't like inline fours in bikes - the high frequency vibrations feed through footpegs and handlebars and are annoying when just cruising along. I will definitely need to use rubber mounts for the motor in the dp1. Yes, the bike is cool. No, I don't want to have it as a motorcycle. In other words, it's perfect for what I need. The garage is definitely getting crowded. I need extra space soon. In the meantime the Duck will again move to the living room for the winter and once I disassemble the bike most of the parts will live in the spare bedroom, just like the Westfield bodywork did. Seems to be a seasonal pattern for me :)

09/01/02 I suppose today marks the official start of construction. Even though it's really deconstruciton - I've started taking the Hayabusa apart.

It has spent all of 33 miles of its life as a bike. Now the metamorphosis begins. Scary, in a way. The parts are migrating into the spare bedroom. Some I will use...

and some will need to go.

It's going to be a whole lot of work. I really hope I'm up to the task. On the plus side, it's neat to see how the bike was designed and put together. A learning experience all in itself. I think I'll end up using more of the parts than I had originally anticipated... Also it looks like there have been a few changes for 2002 model year. Interesting.... 09/07/02 With the parting of the engine and the frame, the disassembly of the bike is now complete.

It took quite a bit of effort and some inventiveness to do this single-handedly. Once it was out, I weighed the engine. It's 180 lbs complete with gearbox, clutch, starter, alternator and throttle bodies. Pretty impressive for a 175 hp powerplant. The rest of the bike is getting some bidding activity on e-bay, although it is not up to my reserve price yet. But it's close, and there are 3 more days to go in the auction. 09/24/02 The whole bike didn't sell on e-bay so now I'm having to part it out. What a pain.... In the meantime, did a lot of measuring of parts and got the basic drivetrain components into CAD.

Of course it will take a whole lot more work. The frame needs to be triangulated and tweaked, the brackets, shafts and couplers need to be designed, etc. So it is going slower than hoped for. Not a terribly big surprise. At least it's going...

|