|

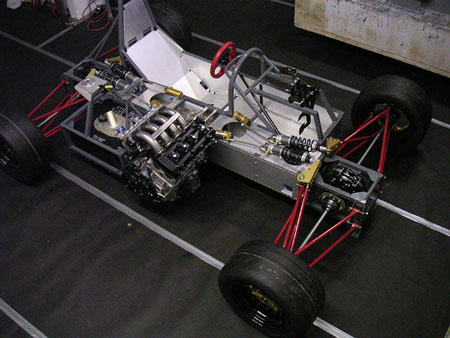

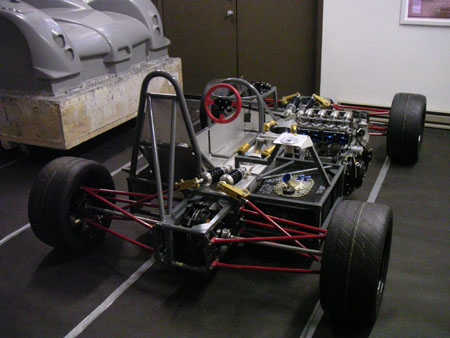

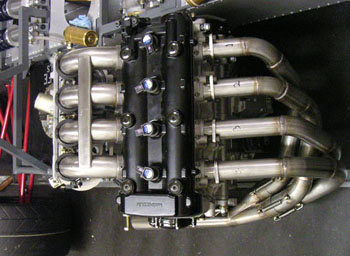

07/02/05 A big step today (though many remain). I'll just let pictures speak for themselves :) 07/26/05 Received the exhaust.

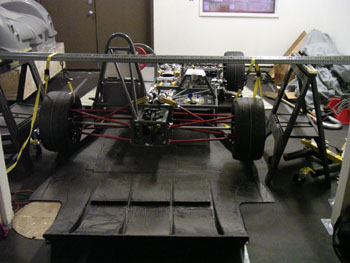

It took some doing to get the one-piece floor under the car to check the fit. Definitely have to split it into sections for production (both from installation and repair/replacement standpoints). The floor in general is going to see some evolution and I was pretty much anticipating this so it's not a big deal.

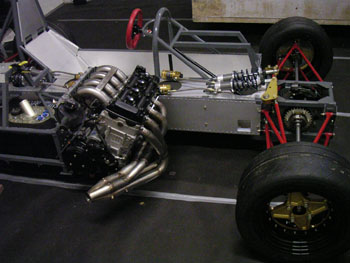

The exhaust was a bit of a gamble on my part - I had looked at the Stohr cars and it seemed like his exhaust would fit mine, so it would make sense to have one made using existing jigs. The caveat was that I was only able to look at Yamaha R1 motor installations, not the Hayabusa ones. I was told that the 'Busa header is similar - and it is. The problem is that in the R1-based cars the collector is in front of the engine (which would work fine for me) but on the 'Busa ones it's a few inches off to the side. Not an issue in Stohr DSR, but in my car with the motor offset to the right already, it doesn't fit. Not a huge surprise since I suspected it might be the case and was mentally ready for it, but now I have to figure out whether to try and modify the existing part or just make a new one.

Making a new one might be the better approach and maybe I can sell the existing part to a Stohr customer at some point. It's not a whole lot of money (I got a very good deal on it) so I'm not too worried about it. While I'm sorting out the exhaust, plumbing is next on the priority list. I'll have to get dry sump and fuel header tanks designed and fabricated, select and buy an oil cooler, then get all the fittings, hoses, etc. and put the whole thing together. Quite a few brackets to make as well. I've got my work cut out for me, in other words. If it were easy.... 07/28/05 On far less serious note, I spent a half-hour sketching logos for the car and the car company. OK, I have so many more important things to do, like actually coming up with drawings so I can get the exhaust re-made. Or designing the dry sump tank, fuel header tank, shifter, gas pedal... Not to mention actual work-type work which I'm behind on. But my brain being what it is, when an idea gets into it, the best way to let it go is to go with it.

All of the above are variations on the 'dp' theme (which is also the Random Research logo, rotated a bit). Even the lizard. The lizard has some significance to me personally and with the car intended to be small, agile and all-wheel-drive it kind of fits. The resemblance to a certain Italian car company logo is somewhat coincidental and I wonder whether people would notice and whether they'd think it humorous or lame. Guess I'll find out. I suppose if I made it black on a yellow background that would be too much - but it's tempting, I happen to like the combo. Need to give it more thought. Someday. For now, back to work. UPDATE: After it was pointed out to me that the lizard is very similar to Wiesmann logo I modified it a bit to be more dragon-like and to more clearly follow the 'dp' shape. I kinda like the result...

UPDATE: I got some good feedback from a number of people and decided that the lizard will be more of a mascot - it will appear on some items like T-shirts and such, but the dpcars logo itself needs to be simpler. So the result is what you see below

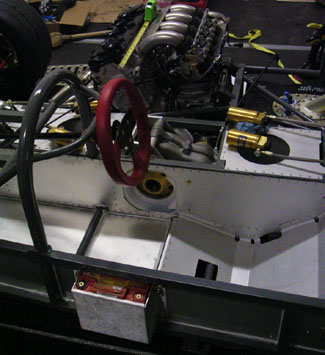

The design is also meant to resemble a 'curves ahead' road sign... Which just happens to be my favorite, for obvious reasons :) 08/23/05 Progress has been slow lately. Part of it is the need to do other things, part is the lack of emotional energy. Just had to take a break I guess. Well, at least I've mounted the battery.

Don't know if that's its final location but it'll do for now. I have to remind myself that what I'm building is a prototype and proof of concept so I shouldn't spend hours agonizing over every little detail. In that spirit, after giving a whole lot of thought to what to do about the exhaust and trying to model it in CAD I ended up just taking some measurements and making a very rough hand sketch with some basic dimensions. I then sent the sketch to the guy who makes the exhausts and let him do his magic. We'll see how it turns out. I'm also having some CV joint spacers made. I knew I'd be needing them because I designed the halfshafts intentionally about 1/4" too short just in case - it's easy to add spacers but hard to shorten halfshafts. Another reason for doing that is in case the center front brake doesn't work I can put a rotor on each halfshaft, the rotor carriers would replace the spacers. Yes, I have contingencies for some things. And finally, I had some discussions about fabricating the drysump oil tank, the fuel header tank and the gas pedal mechanism. I do need to get those into CAD before they can get made, no cheating like with the exhaust. Ah well. I'm waiting on a few drivetrain parts (UPS lost them so they're getting re-made) before I do final assembly on the chassis, tighten everything up and do the initial alignment. That'll be a big step although the car will not look any different than it does now. In other news, after trying to get the one-piece floor under the car I came to the conclusion that it's an idea that is neat in principle but fails miserably in real life. So the floor will need to be sectioned into 3 pieces. I also need to start working on the internal panels, hardpoints, mounting brackets, etc. To that end I need to get the molds from Scappoose. The floor mold of course is a big heavy piece that will require a forklift again. Sigh. So it goes. Really ought to take care of that next week though. Then there'll be lots of messy composites work. The whole thing has been running in my in-head simulator for a while so I basically know what needs to be done, it's just a matter of doing it. 09/16/05 Well, the good news is that the exhaust V2.0 is here. The bad news is that I was too aggressive on one measurement, trying to get it as far away from bodywork as possible, and ended up with the pipes touching the side of the engine...

I think this should be fixable with relative ease without redoing the whole thing. Sent e-mail to my vendor, we'll see what he says. The guy definitely does nice work - just have to give him the right dimensions! Duh. I should have taken the time to do the thing in CAD, at least then I could have checked clearances. Or I should have just measured correctly. Lesson learned? We'll see. In the meantime, other bits and pieces are trickling in. One of the tasks on the agenda is to assemble the drivetrain and get the initial suspension setup dialed in. That'll take some effort. Of course to complicate things the rear diff is leaking so I'll have to take it apart and re-seal - not a pleasant task but necessary because it's oiling the rear brake rotor. And so it goes. |