|

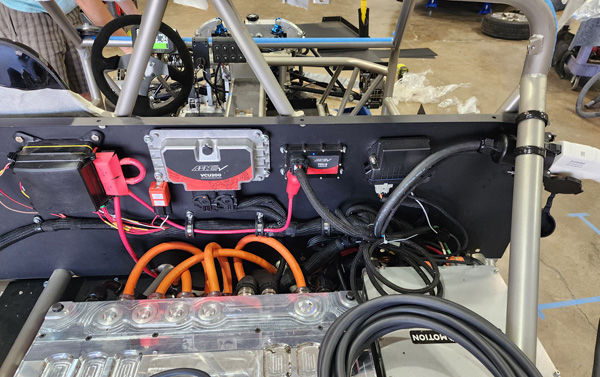

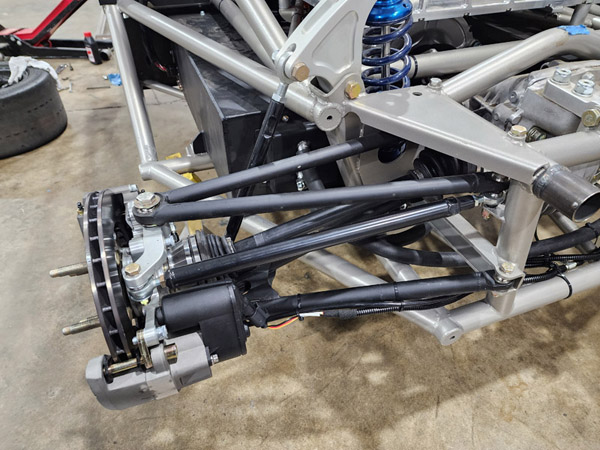

10/21/23 There is so much going on that I haven't had the energy for a blog post here. Even though some very significant developments have occurred with D47 - including its first, and then second, track outing. Read on. The first track drive date was set at August 18 and we had some work to do to get the car ready. Mostly getting the systems finished up, dash programmed, VCU settings to their initial state (to be evolved).

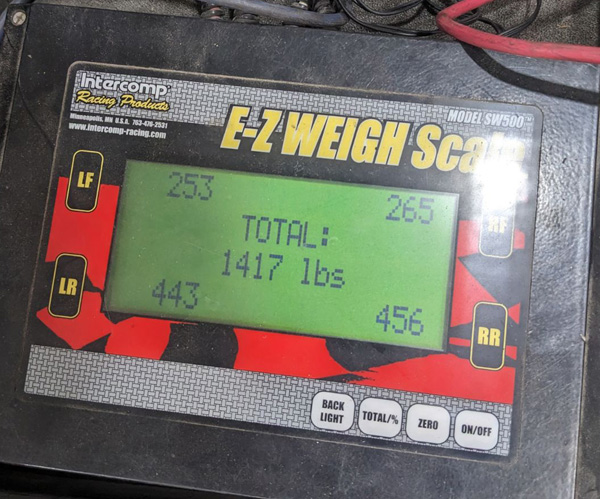

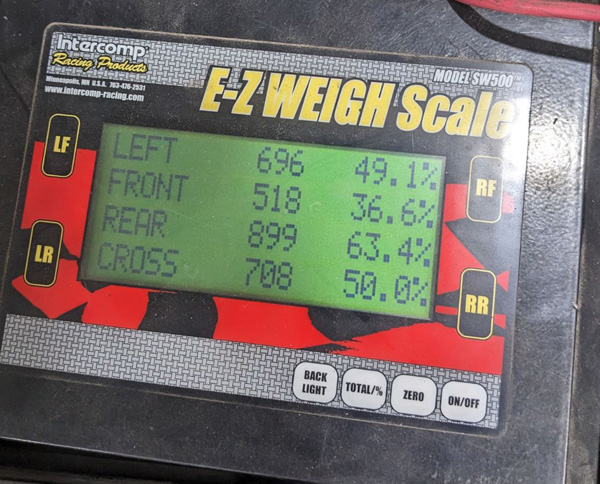

With that done enough for first try, time to put it on the scales. About 250 lbs more than the gas version in roughly the same state of assembly, but also double the peak power (500hp vs 250hp for gas car). Of course we won't be using anywhere near that to start.

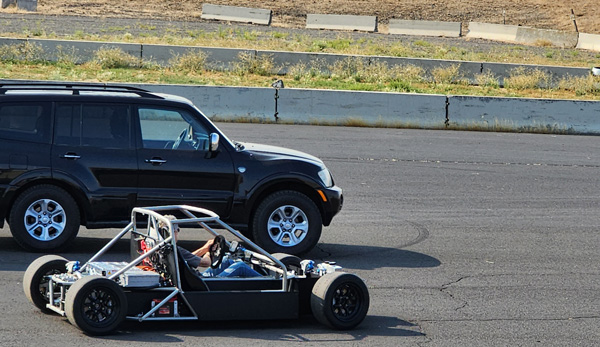

Loading and transport are uneventful. Nature has challenged us with a 105F day, so it's a good test of the cooling systems. And nice not to have the bodywork on.

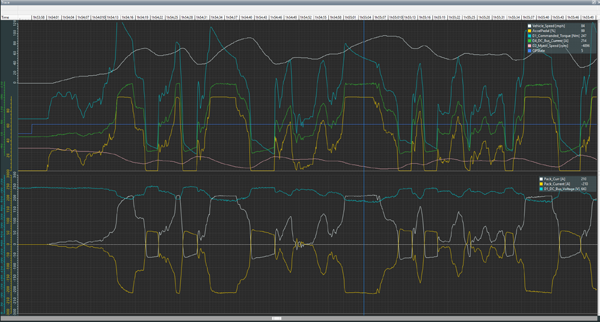

There several computers running the various systems, all of which decide to set limits to performance based on their own parameters. Programming the whole mess is a bit of a challenge. We'll be doing our own systems eventually, but this is a good learning curve. The battery pack is 800V nominal (675V under load), capable of 600A which comes out to 405KW (540hp) of available power. During the day as we chase all the various nannies we seldom see more than 200A. I get a session in with 400A limit, and that is FUN :) Here's a video of a lap. One goal is to get an idea of the kind of range we can expect with the 30KWh pack. We get about 20 laps, which is 50 track miles, at this pace. The pack is also set to only charge to 80% to preserve it for now. So reasonable. 10KW recharge from the available 50A RV plug is slow but gets us 1/3 pack back over 1 hour lunch.

With 105F (40C) ambient the battery temp never gets above 45C, so the liquid cooling of the battery is really not needed. There isn't any heat being removed at this temperature delta. All in all, a great day and much learned. Back at the shop, a number of revisions before the next event: 1. Redo the pedal plate for better pedal placement

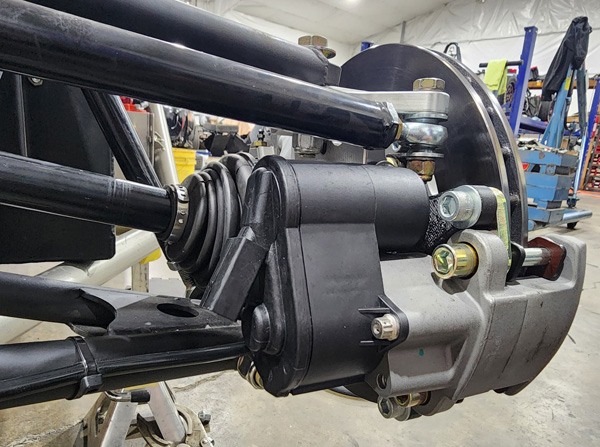

2. Add electric parking brake - with no gearbox to leave in-gear, the car had to be chocked when parked

3. Mess with software limits and better understand which nanny does what and how to get them to clock out.

4. Add slider to the driver's seat since the pedals are fixed.

5. Do initial fit of the bodywork.

We succeed with all of the above to varying degress. For the next track outing we want to use the D4 trailer towing with the Mazda, so that we can also bring out the D2 in the big trailer. The D47 fits fine without bodywork... not so much with. It physically fits, but weight balance is unacceptable facing either forward or back.

So the body comes off again and we run without. Another great test day, but for whatever reason (to be determined) we're now limited to 210A and so there is no point in video or photos really. That's development - incremental steps, some forward, some not. We got some good data, so there's that. And fun was had. Onward.

|