|

04/25/08 At the end of the day the sun was out. When this doesn't happen very often, as has been the case of late, one really learns to appreciate the opportunity and an effort is made to make the most of it. So we did, with a nice Bikini run. Wore helmets this time and it really makes a difference. So the car is exactly like a motorcycle - you need to dress the same way and with proper gear it's manageable. M got to drive it on some twisty roads and later when we dropped by Larry's house he drove it too. He liked it :)

After the run I wanted to put Kermit up on the lift so I can adjust the front A/R bar, so we moved the cars around the driveway. The logistics seemed a bit involved but made for a couple photo opps. Almost felt like pulling the bikes out too... Just kidding. I do need to do it, but that's a whole separate story for another day.

05/03/08 The rodends showed up from TMI a couple of days ago so today I finally got around to installing them. Removing the pushrods gave me a good opportunity to find out what the unsprung weight really is, as well as to set the corner weights afterwards.

First thing I did was weigh the car as it sits, complete with all fluids and about 6 gallons of fuel. The only thing still missing is the rollbar which will add another 20 lbs. Gas is about 40 lbs of the total, so figure 1,250 lb empty 'curb' weight. Not bad for a 400 hp V8 - about same as a '70s F1 car :)

Next on the agenda was supporting the car on jacks and dropping the lift to remove all the pushrods. This leaves just the unsrpung weight on the scales (minus pushrods themselves and the moving part of the shocks, so I'd add about 5 lbs to each corner). Now granted there is some error due to bushing preload since this was a bit above neutral ride height and I would assume (?) that Brammo had tightened the bushings once the car is resting on the springs (raising the lift relative to the car on jacks moved the numbers as high as 110 lbs all around, but now the bushings are working in the other direction). The real way would have been to actually loosen the bolts but I didn't feel like messing with it so this admittedly unscientific test will have to do.

So all in all call it 70 lbs, approximately. Which is actually not too bad - I was expecting more. What matters is not the absolute number but rather the sprung/unsprung ratio. Taking the 70 lb per corner number as a reasonable approximation makes for 280 unsprung and about 1,200 sprung, with driver and fuel (which is what matters). So about 4.25 sprung/unsprung ratio which is OK for a light car but not stellar. In comparison, the dp1 has 41 lbs unsprung per corner and is about 1,100 lbs with driver and fuel, so 936/164 is about 5.7 ratio - inboard brakes help, as does emphasis on weight reduction. A typical 3,000 lb sedan with OEM 17" wheels and tires has roughly 110 lbs per corner unsprung so the ratio is 2,560/440 or 5.8. The reason this matters is that from a dynamics standpoint, the sprung weight is what's pushing the wheels/tires down into the pavement. The unsprung weight is what wants to bounce up and down (just roll a wheel and tire over some bumps even at low speed and you'll see what it wants to do unrestrained). So the higher the ratio, the more control there is over the tires and therefore the contact patch. Explains why the Atom tends to bounce over bumps a bit. I just dialed in more damping, we'll see how it affects things. This out of the way I installed the new rodends and set the corner weights. With me in the driver's seat and fuel in the tank, the numbers look like this:

A passenger would even it out just about perfect. This should do for the moment. Now I need to get rollbar modified, a few electrical and oil-related loose ends to wrap up, a few more miles on the motor and then it should be ready to hit the track. Shooting for May 23 Lotus club day. While I was messing with the Atom M was installing the frame sliders and the new battery on the 748. She did it herself without any help from me including cutting the fairinigs. I know, I'm a lucky guy :) After this she went to a store, bought the ingredients and made awesome oatmeal and raisin cookies, blasting Marilyn Manson on the stereo all the while. I must be dreaming.

A bit more Bikini progress, among all the other stuff. Over the weekend Jared, my brother-in-law, fabricated the rollbar braces to fit around the engine.

Looks good and should work well. The silver bar detracts from the lines of the chassis tubes, in my opinion, so I'm going to have it powdercoated black. I'm also going to paint the tube that goes above the mufflers black as well (it's being blackened by the exhaust anyway). Below is a picture of the car as-is and a photoshopped one showing approximately how it will look when done.

The bar is now at the powdercoaters, should be back next week. In the meantime there are several other things that need to be taken care of. The oil pressure gauge sender seems to have died (scared me for a moment but since I have two gauges and the other one was showing pressure I quickly realized that it's a gauge problem and not actual lack of oil pressure). A new one is on the way. I need to fabricate a shield for the oil pump belt, it's getting a lot of crud on it from the road and won't last long like this. Also a better venting setup for the oil tank is called for, right now I'm getting some oil spraying out from the vent cap. A better fire extinguisher mount would be good too, the cheap one I put in broke loose on the last drive (should probably get a halon extinguisher anyway). And finally I don't have a speedo sensor hooked up, need to get a connector and then probably do some calibration too. So quite a few things on the laudry list but all are manageable and some are getting done. 05/19/08 (updated 5/20) Finally a track outing for Bikini. Proper Bikini weather, too - nearly 90F. The rollbar is back from powdercoaters and installed, fire extinguisher is now Halon and the new venting system for the drysump tank is on the car. Time to see how well it all works.

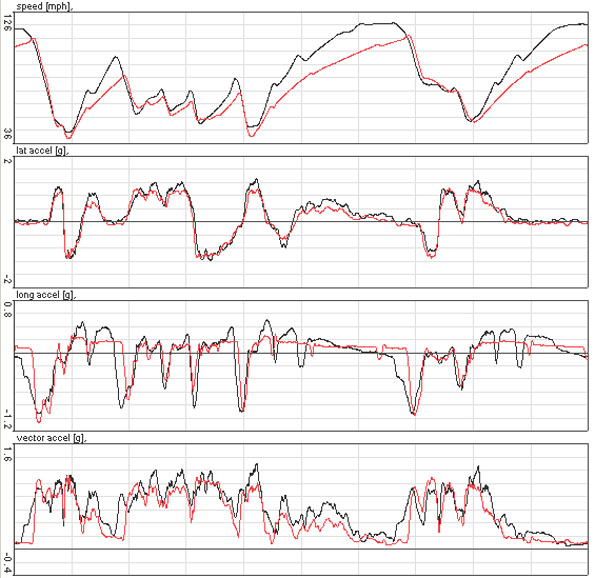

The first session was just getting a feel for how the car behaves on the track - turns out it's pretty composed and a lot of fun. The motor still has only about 200 miles on it so I set the rev limit at 7K RPM and resolved to be gentle with throttle and shifts. About half a dozen laps into the first session I get a 'meatball' flag - mechanical malfunction. Quick check of the mirrors showed no open flames so I finished the lap and pulled into the pits. No flames but smoke, definitely. There is oil all over the place including on the exhaust. A quick survey reveals that my drysump venting system is failing miserably and dumping oil on the whole left side of the car, including the tire. No wonder it felt a little funny in the last few turns. Some head-scratching and some help from Tristan produced a solution to try. Next session the plan is to take 3 laps then come in and check status. I do three laps, pull in - damn, still oil all over the place. Plan B replaces the filter on the catch tank with a cap and a further restriction in the vent plumbing. Third session same routine and while the result is better, it still is not perfect. So I need to come up with a whole new solution here. I therefore park the Atom and run the last session in the Mini. But I did get some initial data and it is quite interesting.... Below, the Atom trace (black) is overlaid with the Mini trace later in the day (red). Now keep in mind that this is still short-shifting well before the 11K rpm redline and taking time with the shifts themselves too.

The flattening of the speed curve at the top is because I reach 7K rpm in top gear and just cruise from there. Peak forward acceleration is a bit over 0.5g even at this reduced pace. The car is FUN and the above lap was an easy 1:30.6, without trying hard at all, and was only the second lap in the second session. So there's much more to come - and much work to be done still. On with it then. UPDATE: After taking apart the drysump tank and making some changes to baffling (we'll see how it all works Friday I guess) I decided to belatedly make the obvious comparison - Bikini to dp1 prototype. The first set of traces below is the Atom (black) vs. early dp1 proto (red), basically first trackday to first trackday.

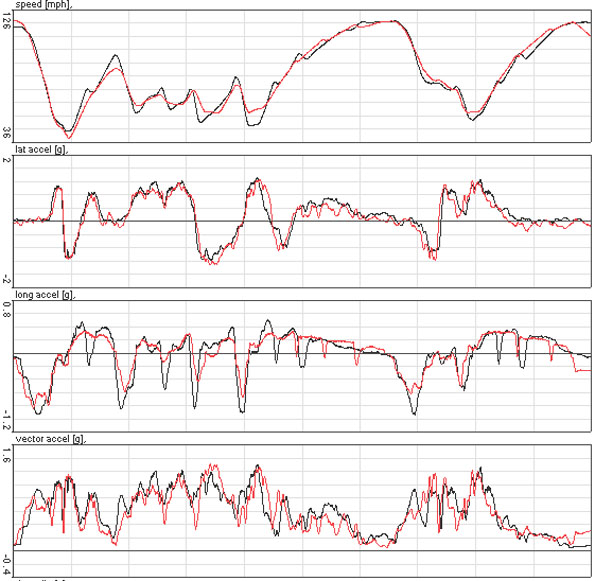

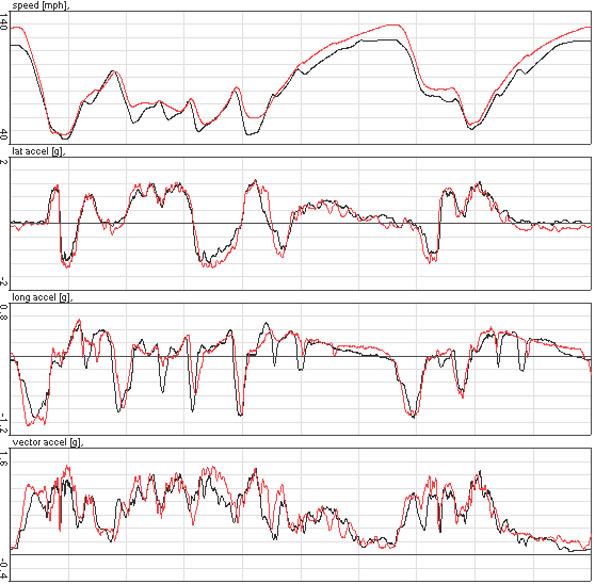

The times are pretty close, dp1 at 1:29.6 and Bikini at 1:30.6. It looks like I'm a lot more liberal with the Bikini engine (there's a lot more engine there) but cornering-wise dp1 is clearly ahead which is where the 1 sec difference comes from, mostly. More tire, less weight and better suspension so it's no surprise, although the Atom still has more to give. The next set of traces is the best recorded dp1 proto lap (1:24.2, red) vs the same Atom lap (OK, it should really be in the teens but I've got a lot to learn still as a driver).

Just using the dp1 proto better yielded another 6.4 seconds and of course the car can do more. Notice that the dp1 now accelerates at least as well as the Atom and better in some places. And that's a 180 hp car, albeit about 400 lbs lighter. Vs 400 hp. Obiously I'm not using Bikini anywhere close to potential yet, so I think it's a 1:25 or better car even in my hands. Time will tell, of course. And then the dp1 will get an even bigger/more powerful v8, less weight, more downforce and proper racing slicks that it can actually heat up... ;) 06/19/08 I tried modifying the original dry sump tank to solve the issues but the bottom line is that it's just too small, which isn't helped by the fact that it has to be mounted at a 30 degree angle. So I went through a half-dozen alternative designs and settled on a tubular shape that's 5" taller at 18" vs original 13. Some searching on the web produced a nice 14GA, 15" tube and a few fittings. The rest of the bits would be cannibalized off the old tank. I designed a baffle system that would account for the tilted installation and Jared did most of the fabrication (I helped by making some of the parts but he did all the welding). Mounts had to be modified also and I did all of that. Took a few hours but the result looks promising...

The resulting tank holds 75% more oil which should help with the slight pressure drop in the right-hand turns that I experienced previously. Old tank could only be filled about 1/2 way before it started spraying out, the new one can be filled almost to the input port and still have air space above for de-aeration. The venting system will take a few tries, I'm sure. The first approach is to just put a vented/filtered cap on it and see how it goes... Since the new tank is one piece getting it in the car required a lot of disassembly. The air filter and its mounts and ducting, engine cover, overflow tank, left shock absorber - all had to come out. Then once the tank was in (with 1/4" clearances on many sides, as usual) all the parts had to be reinstalled. All buttoned up it was time for a quick test on my local twisty road. The oil pressure stayed steady throughout which was good and M enjoyed the few bursts of acceleration between turns, with the rear tires scrambling for traction and tail sliding just a bit. Only 3/4 throttle, too. Upon getting back there was some minor oil leakage from the vent cap. Ugh. I was hoping that the mild exercise on the street would not cause any oil to flow out but I did put in a bit more oil than was called for, just as an experiment. Tomorrow is a trackday and I'll do more testing then. For now, a shop rag zip-tied around the vent cap should keep things somewhat contained.

I have a contingency for a solution if that doesn't work. We'll see how it goes tomorrow. What I have now is definitely better than what I had before so it's progress. |