|

06/02/07 Well, it's time to get back to work on Bikini. To this end I've decided to move the car to the garage at the house for easier and more immediate access. The lift will be a help too. The trip was easy - loaded up (this is becoming a routine now), trailered to the house, unloaded.

I definitely need to clean up the garage. This will be a good excuse to do it. Out in the open the car looks pretty neat, it's good to see it from a distance. The rollbar is definitely going to get powdercoated flat black. Over the past month there has been some steady progress on details - connected more plumbing, got a new oilpump belt tensioner pulley made, etc. I have this coming week to make some real progress after which it will have to sit until July. Such is life. 07/13/07 It may not seem like there's much progress but there are actually lots of things going on, some of which are pretty exciting. The dp1 has finally proven to be enough of a resume that I now have a design project for a bonafide automotive client, paying real money even. A few discussions are also taking place regarding moving the dp1 project forward and its future, although nothing is set yet. In the meantime, one of the many changes in my life is that I have lost the shop space where the dp1 was built so after coming back from Europe I had to scramble to try and find an alternative. Nothing useful came up in the two weeks so yesterday I had to move everything into the garage - the dp1, the buck and the mold. Of course the Atom and the MINI were already in it. The move was quite an ordeal because the buck in particular is very heavy and hard to maneuver without a forklift. But hey, I'm an engineer so I figured out the ways and means. Took from 10am until 4am this morning to get everything moved, get the garage cleaned out and organzied (somewhat), take the mold apart and figure out where to put the various pieces. But in the end it all fits - barely.

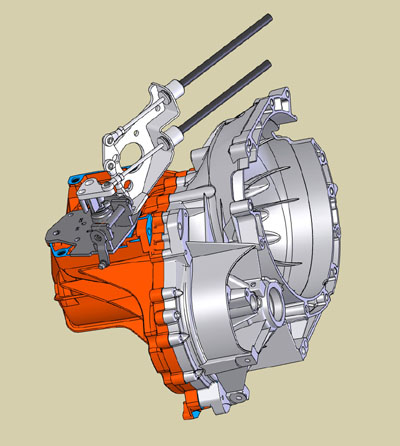

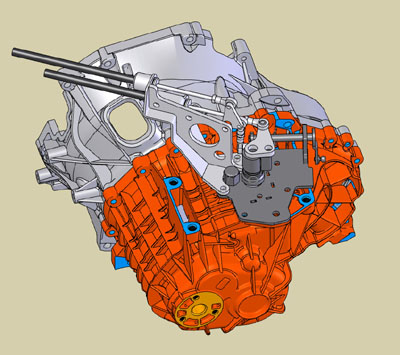

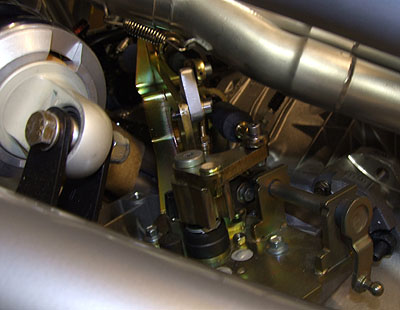

There's even some room to work on the Atom, kind of. It'll have to do in the near term. I'm glad I'm into small cars! The dp1 isn't going anywhere anytime soon but it's just as well since the next phase of testing and development primarily involves Bikini. The mold needs to be cleaned up too so that'll be easy with it sitting on its side like this. Whew. 08/14/07 OK, this is the honest push to get this done. To that end I finally figured out a shift linkage arrangement that I'm somewhat happy with - it's out for quotes now. It was a real pain and there is a possibility that it might flex in one direction but this is all that space will allow. Hopefully I won't have to redo it.

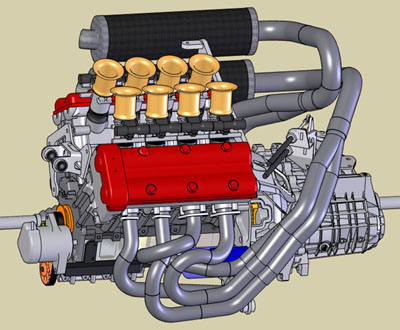

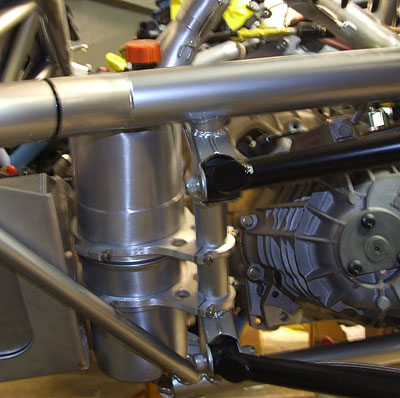

We'll see how it works. Time is running a bit short so I'm setting aside other projects as much as possible and just working on this one. A lot of minor fabrication remains but I know it can be done. After some discussions with John Hartley we came up with a really cool airbox design for the motor (well, I made a suggestion and he did all the hard work :) so that should be showing up shortly. It should be a treat and I wonder why at least some manufacturers don't do it this way - would be really cool on engines like the BMW V10. You'll see what I mean when I post the pictures. 08/21/07 The shifter is fabricated, along with a couple plumbing bits. Installed it and lo and behold the thing works. Clearance to the exhaust is really tight but that's an ongoing theme with this car and clear it does. The rubber boot probably won't live too long unless I come up with an effective shield which should be doable. There are a couple minor tweaks that I need to make and I'll try to get it plated this week.

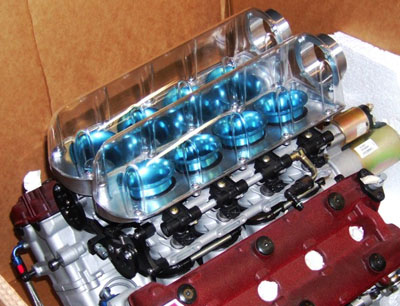

Lots of parts are on order, some are here and fabricated. So there's definitely progress but it's going to be really close for next week. Might just have to run the MINI at the Lotus day and save Bikini's debut for later. I'll keep trying though. We'll see. The airbox is not here yet but John has sent a couple pictures. The clear top allows the intake trumpets and throttles to be seen which I think is pretty cool. It always seemed a shame to hide those neat mechanical pieces inside a black airbox, especially on the Atom where the engine will be mostly exposed. We'll see how it looks on the car but so far I like it!

08/24/07 The calendar is moving along but so am I. Got a few of the parts today and spent some time figuring out how they will fit. The first is an air filter. It has two 2.75" outlets to match the intakes on the airbox and has a bit more than double the area of the stock panel filter that Brammo supplies. Needless to say, fitting it requires quite a bit of cutting and fabrication. The cutting is now done and I know exactly how I'm going to do the attachment points. The final mounting is tomorrow. Then I can do the overflow tank too, and that will let me finish water plumbing (but not without more cutting of course!).

Another thing that came in today is the laser-cut blanks for the oil tank mounts. The design is a bit of a trick - it's cut as one part (this way I only get charged for one part instead of the three that I'm really making). I will first drill the clamp bolt holes which will ensure they're aligned, then I'll separate the three parts and sand them for a reasonable finish. Anodizing, if I choose to do it, will come later.

When the mounts are done I can secure the oil tank and then finish the oil plumbing too. After that, fill the various fluids and move on to the wiring. The shifter parts should be back from plating Monday or Tuesday, some gauges and miscellaneous bits should be showing up around then as well. Tick tock.... :) 08/25/06 Some more progress. The oil tank mounts worked out pretty well. Quick, easy and relatively inexpensive. The tank is now in. It is pulled tight against the frame rails on both top and bottom and is vertically supported on the lower frame rail so the fact that the mounts are both close to the middle is not an issue. As with everything else, clearances are 1/8"-1/4" all around.

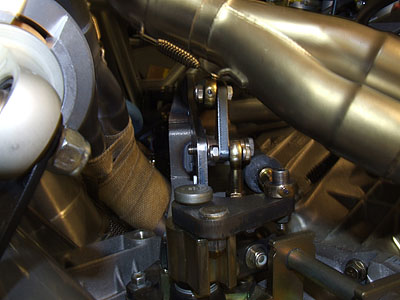

Finishing up the water plumbing is next. After all the rest of the sundry bits are in, some additional exhaust shielding will be in order. 08/28/07 This is turning out to be a real race against time. To help, John is flying down tomorrow to assist with the startup. In the meantime there is some progress. The shifter is back from the platers and installed. Looks completely like a factory part. It's a little hard to take a decent picture of it so the one below will have to do. It works quite well, too.

The oil plumbing is done except for hooking up pressure sensors on the supply and scavenge sides (I need to monitor scavenge pressure because of the unorthodox way I'm doing that section). The gauges are here, too. The water plumbing took a few tries but I finally have a solution I'm reasonably happy with. Yes, as with everything else, clearances are minimal.

It's really starting to look like a car now. Every time I go through this (first with the Westie, then the dp1 proto, and now with Bikini) I"m reminded just how much there is to making a functional vehicle. And how everything is connected to everything else. On a final note for today, the airbox showed up. Looks sweet! It will be quite easy to make a half of it for any Hayabusa-powered car, so if you have one and want an airbox like this drop John a line through his site. It will likely poke through the hood on most 7-like cars but with something that looks like this you'd want it to!

|